35

4) HEATER

Failure

Cause

Diagnosis of Failure

Solution

PCB

Status

Error Mode

Can not

heat

water

Overheat

water

Can not

dry

Wiring Disconnection

Heater Wash

Disconnection

Connector/Terminal

Seclusion

Heater Wash/Thermistor

Wash Poor

Heater Wash/Thermistor

Wash Poor

Wiring Disconnection

Heater Dry Disconnection

Fuse Temp.

Connector/Terminal

Slipped out

Operation Trouble of FAN

MOTOR

Heater Wash/Thermistor

Fault of Thermistor (Dry)

Connecting the

disconnecting point

Replacing Heater Wash

terminal/connector tightly

Connecting

Replacing temp. sensor

Replacing Heater Wash

Inserting terminal/connector

Replacing Fuse Temp.

tightly

Connecting

Re-connecting

Replacing Fan motor

Re-assemble after

disassembling

Replace Thermistor

Check whether disconnected or not : See Fig. A

Check whether disconnected or not : if normal, the

resistance between two ends is 23.3~25.7

Ω

.

Check whether disconnected or not : See Fig. A

Measure the resistance of two ends of the sensor : if

11.981K

Ω

at R25, it is mormal

Measure the resistance of two ends of the sensor : if

11.981K

Ω

at R25, it is mormal

Check whether disconnected or not : See Fig. B

Check whether disconnected or not : if normal, the

resistance between two ends is 22.3~24.7

Ω

.

Shipped out

Check whether disconnected or not : See Fig. B

Excessive Noise : Restraint/Failure of Fan Motor

Fan slipped out : MOTOR is operating, but there is

rotating sound.

Measure the resistance of two ends of the sensor : if

26.065K

Ω

, it is mormal

"H6"

"H6"

"H6"

"H2"

"H2" or "H4"

"H7"

"H7"

"H7"

"H7"

"H7" or "E3"

"H7"

"H1"

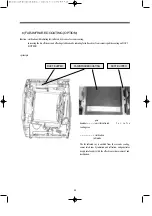

Checking Method of wiring/coil disconnection, connector slipping out on PCB board : Operate with the heater connected

* Inspect Wiring/Heater

Wash Disconnection :

Check the current and

resistance of two

terminals

3P Connector

orange wire

1P Connector

Blue Wire

* Inspect

Wiring/Heater Dry

Disconnection :

Check the current

and resistance of two

terminals

3P Connector

Red Wire

1P Connecor

Blue Wire

[Figure A]

[Figure B]

Summary of Contents for DWC-ED1213

Page 10: ...7 3 VERIFICATIONOFDRUM ASSY...

Page 11: ...7...

Page 16: ...12 3 CABINETFAS...

Page 19: ...15 5 DUCT DUCTPIPEAS...

Page 21: ...17 6 CABINETAS...

Page 23: ...19 7 BASEUAS...

Page 25: ...21 8 TUBAS...

Page 51: ...47 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE 7 Wiring Diagram...

Page 52: ...48 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 53: ...49 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 54: ...50 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 55: ...51 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 56: ...52 DWC E1213 DOUBLE VALVE BUBBLE DWC E1213 DOUBLE VALVE N BUBBLE...

Page 57: ...53 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 58: ...54 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 63: ...2005 09 DRUM WASHING MACHINE 686 360 8282 http www dwe daewoo co kr...

Page 64: ...SVCMANUAL DWD E1200R S DWD E1200W S 2005 09 DRUM WASHING MACHINE DRUMWASHINGMACHINE...