30

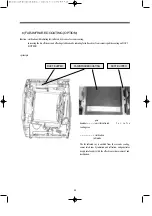

4. ERROR DISPLAY

ERROR

SINGAL

ERROR

CAUSE

COUNTERPLAN

1

inlet valve broken

Change the Inlet-Valve

IE

WATER

2

drain motor working during water supply

Change the Drain Motor

INLET ERROR

3

pressure switch disorder

Change the Sensor Pressure

4

PCB can not check water level

Change the PCB

1

drain motor out of order

Change the Drain Motor

OE

DRAIN

2

inlet valve working during drain

Change the Inlet-Valve

ERROR

3

pressure switch disorder

Change the Sensor Pressure

4

PCB can not check water level

Change the PCB

UE

UNBALANCE ERROR

1

laundry unbalance

rearrange the laundry

1

door opened during processing

Clode the Door

LE

DOOR

2

LOCK S/W broken

Change the LOCK SW

OPEN ERROR

3

PCB can not check door lock

Change the PCB

1

continuous water supply

Change the Inlet-Valve

E2

Overflow

2

drain motor can not work

Change the Drain Motor

3

pressure switch disorder

Change the Sensor Pressure

E3

FAN MOTOR

1

fan motor cannot work

Change the Fan-Motor

disorder

2

PCB cannot control fan motor

The contact of the Connector or Change the PCB

E9

SENSOR PRESSURE

1

abnormal water level

Change the Sensor Pressure

ERROR

1

huge noise

re-installation

E5

HIGH VOLTAGE

2

spining with jamming clothes between gasket

rearrange the laundry

ERROR

3

PCB broken

Change the PCB

1

huge noise

re-installation

E6

EMG ERROR

2

spining with jamming clothes between gasket

rearrange the laundry

3

motor broken

Change the Motor

4

PCB broken

Change the PCB

E7

Direction Error

1

move opposite direction

2

motor Hall IC broken

check the connector and change

E8

motor disorder

1

connector problem

The contact of the Connector

2

abnormal loading condition

check the loading condition and change

H1

sensor temp.

1

sensor temp broken

Change the Sensor Temp.

dry disorder

2

connector problem

The contact of the Connector

H2

sensor temp.

1

sensor temp. of washing broken

Change the Sensor Temp.

wash disorder

2

connector problem

The contact of the Connector

H3

overheating

1

fan motor cannot move

Change the Fan Motor

dry heater

2

sensor temp. of dry broken

Change the Sensor Temp.

H4

overheating

1

heater working with no water supply

check water level

wash heater

2

sensor temp. of wash broken

Change the Sensor Temp.

H6

abnormal of washing heater

1

washing heater cannot work

Change the Heater Wash

H7

abnormal of drying heater

1

dry heater cannot work

Change the Heater Dry

H8

abnormal of sensor temp.

1

heater working with no water supply

check the water level and washing heater

of washing

PEF

Pump Filter

1

The drain filter is clogged.

Clean the drain filter

Summary of Contents for DWC-ED1213

Page 10: ...7 3 VERIFICATIONOFDRUM ASSY...

Page 11: ...7...

Page 16: ...12 3 CABINETFAS...

Page 19: ...15 5 DUCT DUCTPIPEAS...

Page 21: ...17 6 CABINETAS...

Page 23: ...19 7 BASEUAS...

Page 25: ...21 8 TUBAS...

Page 51: ...47 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE 7 Wiring Diagram...

Page 52: ...48 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 53: ...49 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 54: ...50 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 55: ...51 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 56: ...52 DWC E1213 DOUBLE VALVE BUBBLE DWC E1213 DOUBLE VALVE N BUBBLE...

Page 57: ...53 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 58: ...54 DWC ED1213 DOUBLE VALVE BUBBLE DWC ED1213 DOUBLE VALVE N BUBBLE...

Page 63: ...2005 09 DRUM WASHING MACHINE 686 360 8282 http www dwe daewoo co kr...

Page 64: ...SVCMANUAL DWD E1200R S DWD E1200W S 2005 09 DRUM WASHING MACHINE DRUMWASHINGMACHINE...