14

6. To remove high voltage capacitor.

1) Remove a screw which secure the grounding ring

terminal of the H.V. diode and the capacitor holder.

2) Remove the H.V.diode from the capacitor holder.

3) Reverse the above steps for reassembly.

High voltage circuit wiring

7. To remove magnetron.

1) Remove a screw which secure the magnetron.

2) Remove the magnetron.

3) Reverse the above steps for reassembly.

DISASSEMBLY AND ASSEMBLY

Never install the magnetron without the metallic gasket plate which is packed with each magnetron to prevent microwave

leakage. Whenever repair work is carried out on magnetron, check the microwave leakage. It shall not exceed 4mW/

for a fully assembled oven with door normally closed.

NOTE

cm

2

Summary of Contents for KOR-637V

Page 5: ...4 EXTERNAL VIEW 1 OUTER DIMENSION ...

Page 27: ...26 WIRING DIAGRAM ...

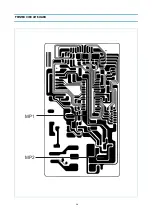

Page 29: ...MP1 28 PRINTED CIRCUIT BOARD MP2 ...

Page 30: ...29 PRINTED CIRCUIT BOARD ...

Page 32: ...31 2 P C B CIRCUIT DIAGRAM PRINTED CIRCUIT BOARD ...