-39-

SL-110P Service Data

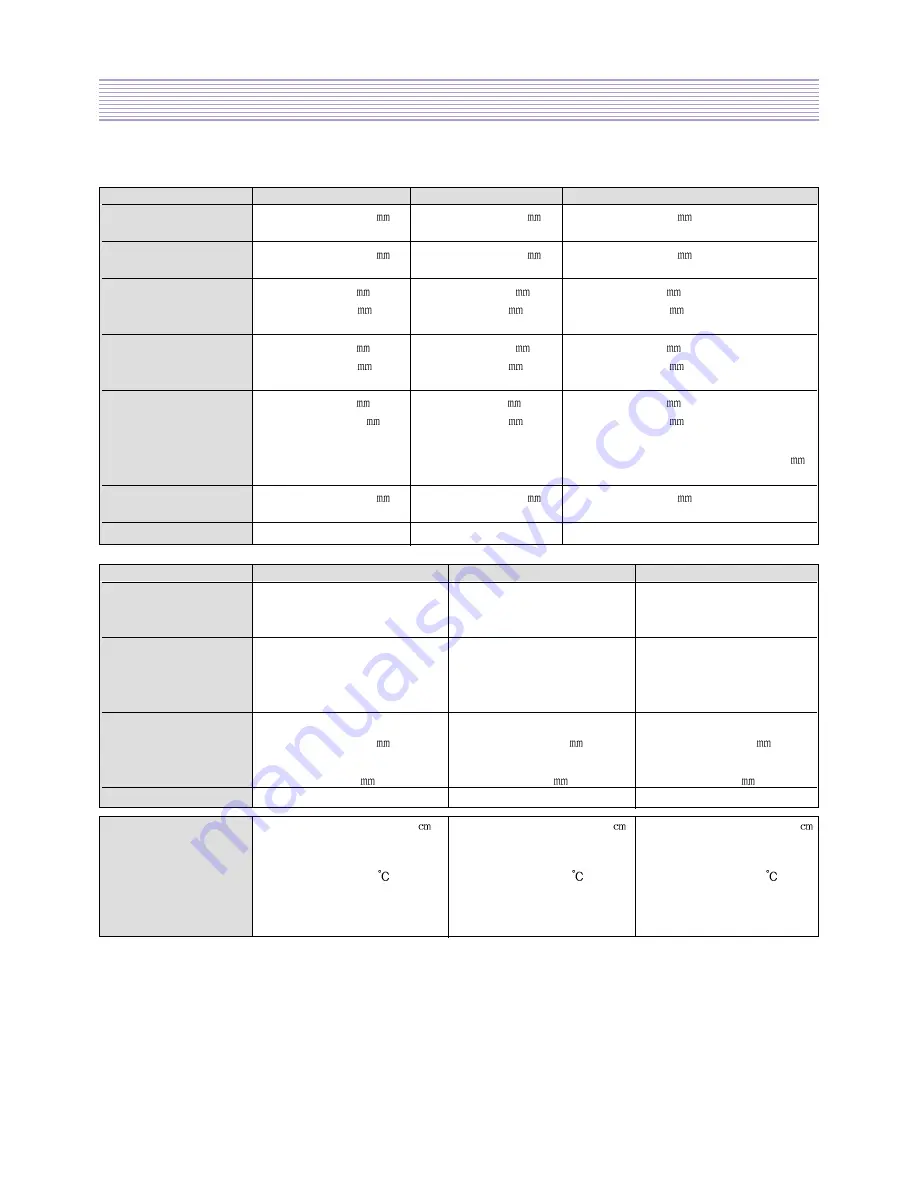

7-6. PANEL DEFECT Test

Visual Inspection

15” SS panel

17” SS panel

20.1” AUO panel

Bright Spot

diameter <= 0.8 .

diameter <= 0.8 .

diameter <= 0.5 .

Numberr <= 4.

Numberr <= 4.

Numberr <= 5.

Dark Spot

diameter <= 0.8 .

diameter <= 0.8 .

diameter <= 0.5 .

Numberr <= 4.

Numberr <= 4.

Numberr <= 5.

Width <= 0.1

&

Width <= 0.08

&

Width <= 0.15

&

Bright Lines

length <= 3.0 .

length <= 2.0 .

length <= 10.0 .

Number <= 4.

Numberr <= 4.

Numberr <= 5.

Width <= 0.1

&

Width <= 0.08

&

Width <= 0.15

&

Dark Lines

length <= 3.0 .

length <= 2.0 .

length <= 10.0 .

Number <= 4.

Numberr <= 4.

Numberr <= 5.

Width <= 0.1

&

Width <= 0.1

&

Width <= 0.15

&

length <= 10.0 .

length <= 5.0 .

length <= 20.0 .

Polarizer Scratch

Number <= 3.

Numberr <= 3.

Numberr <= 5.

(circle scratch : diameter <= 20.0 .

Number <=

5.)

Polarizer dent/bubble

diameter <= 0.8 .

diameter <= 0.8 .

diameter <= 0.5 .

Numberr <= 3.

Numberr <= 6.

Numberr <= 5.

Max. Defects

Numberr <= 7.

Numberr <= 10.

Electrical Inspection

15” SS panel

17” SS panel

20.1” AUO panel

random number <= 2.

random number <= 2.

random number <= 2.

Bright Dot

2 neighboring dots <= 1.

2 neighboring dots <= 1.

2 neighboring dots <=0.

3 neighboring dots <= 0.

3 neighboring dots <= 0.

random number <= 7.

random number <= 6.

Dark Dot

2 neighboring dots <= 2.

2 neighboring dots <= 2.

random number <= 5.

3 neighboring dots <= 1.

3 neighboring dots <= 0.

2 neighboring dots <= 0.

neighboring dots<= 0.

distance between

distance between

distance between

defect min distance

bright sots >=15 .

bright sots >=15 .

bright sots >=15 .

distance between

distance between

distance between

dark dots >=5 .

dark dots >=5 .

dark dots >=5 .

Max. Defects

number <= 7.

number <= 6.

number <= 5.

watching distance : 30 - 50

watching distance : 50 - 70

watching distance : 60 +- 5

Iuminance : 300 - 700 Iux

Iuminance : 300 - 700 Iux

Iuminance : 300 - 700 Iux

(nominal 500 Iux)

(nominal 500 Iux)

condition

temperature : 25+-3

temperature : 25+-5

temperature : 25+-25

angle : front

angle : front

angle : front

pattern : R, G, B, black, white

pattern : R, G, B, black, white pattern : R, G, B, black, white

test : active area

test : active area

test : active area

(1) SVC KEY on the SVC remote controller => PART key => PR DOWN / UP KEY

TEST PATTERN : R, G, B, White, Black (Toggle : PR KEY)

PART KEY : Cancel

(2) Test method : In each pattern of R, G, B, White, Black, Check the DOT DEFECT number.

Summary of Contents for DLP-15D3SHS

Page 7: ...7...

Page 8: ...8...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29 DLP 15D3SHS DLP 17D3SHS TOP...

Page 30: ...30 DLP 15D3SHS DLP 17D3SHS BOTTOM...

Page 31: ...31 DLP 20D3SHS TOP...

Page 32: ...32 DLP 20D3SHS BOTTOM...

Page 64: ...64 DLP 15D3SHS...

Page 65: ...65 DLP 17D3SHS...

Page 66: ...66 DLP 20D3SHS...

Page 67: ...LCD Projection TV Service Training 13 13 SOFTWARE INSTALL SOFTWARE INSTALL...

Page 69: ...2 Copy FlashUpgrader exe in the PW113 folder to PC...

Page 72: ...2 Click the Setup_Visual_I2C_v3 2b18 file twice to execute...

Page 73: ...3 Progress the Install as shown below Select the YES Y button Select the Next button...

Page 74: ...Select the Next button After check I accept the agreement Choose the Next button...

Page 75: ...Select the Next button Select the Next button...

Page 76: ...Select the Next button Select the Install button...

Page 77: ...Installing Select the Finish button...

Page 79: ...5 Progress the Install as shown below Select the I Agree button Select the Next button...

Page 80: ...Select the Install button Select the Close button...

Page 81: ...6 Copy VCTI_D2 folder to PC in the CD...

Page 82: ...7 Restart the PC 8 Run the LptDrvTest in Micronas folder as shown below...

Page 85: ...LCD Projection TV Service Training 14 14 SOFT UPGRADE SOFT UPGRADE...

Page 87: ...Figure 2 Click twice the PwSDK inf Figure 1 Click the Choose button Figure1 Figure2...

Page 92: ...FIGURE 1 Click the TVT button FIGURE 2 Click the Bootloader button Figure1 Figure2...

Page 93: ...FIGURE 3 Normal condition Figure3 Figure4 FIGURE4 Error condition Repeat 2 progress...