8

MMD24S

MMD24B

OPERATION

DESCRIPTION OF OPERATING SEQUENCE

The following is a description of component functions dur-

ing oven operation.

OFF CONDITION

Closing the drawer activates the door sensing switch and

secondary interlock switch. (In this condition, the monitor

switch contacts are opened.)

When oven is plugged in, 20 volts A.C. is supplied to the

control unit. (Page 0).

. The display will show flashing "Enjoy Your Drawer Touch

Clear and Touch Clock".

To set any program or set the clock, you must first touch

the STOP/CLEAR pad. The display will clear, and " : "

will appear.

COOKING CONDITION

Program desired cooking time by touching the NUMBER

pads. Program the power level by touching the POWER

LEVEL pad and then a Number pad.

When the START pad is touched, the following operations

occur:

. The contacts of relays are closed and components

connected to the relays are turned on as follows.

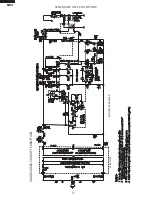

(For details, refer to Page 0)

RELAY

CONNECTED COMPONENTS

RY-

oven lamp/stir fan motor/fan motor

RY-2

power transformer

2. 20 volts A.C. is supplied to the primary winding of the

power transformer and is converted to about 3.3 volts

A.C. output on the filament winding, and approximately

2370 volts A.C. on the high voltage winding.

3. The filament winding voltage heats the magnetron

filament and the H.V. winding voltage is sent to a voltage

doubler circuit.

4. The microwave energy produced by the magnetron is

channelled through the waveguide into the cavity feed-

box, and then into the cavity where the food is placed

to be cooked.

5. Upon completion of the cooking time, the power

transformer, oven lamp, etc. are turned off, and the

generation of microwave energy is stopped. The oven

will revert to the OFF condition.

6. When the drawer is opened during a cook cycle, the

monitor switch, door sensing switch, secondary interlock

switch, relay (RY) and primary interlock relay are

activated with the following results. The circuits to the stir

fan motor, the cooling fan motor, and the high voltage

components are de-energized, the oven lamp remains on,

and the digital read-out displays the time still remaining

in the cook cycle when the door was opened.

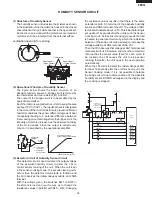

7. The monitor switch electrically monitors the operation of

the secondary interlock switch and secondary interlock

relay and is mechanically associated with the drawer so

that it will function in the following sequence.

8. When the drawer opens from the closed position, the

primary interlock relay (RY2) and secondary interlock

switch open their contacts. And contacts of the relay

(RY) remains closed. Then the monitor switch contacts

close.

9. When the drawer is closed from the open position, the

monitor switch contacts open first. Then the contacts of

the secondary interlock switch and door sensing switch

close. And contacts of the relay (RY) open.

If the secondary interlock switch and primary interlock

relay (RY2) fail with the contacts closed when the drawer

is opened, the closing of the monitor switch contacts will

form a short circuit through the fuse, secondary interlock

switch, relay (RY) and secondary interlock relay (RY2),

causing the fuse to blow.

POWER LEVEL P-0 TO P-90 COOKING

When Variable Cooking Power is programmed, the 20

volts A.C. is supplied to the power transformer intermittently

through the contacts of relay (RY-2) which is operated by

the control unit within a 32 second time base. Microwave

power operation is as follows:

VARI-MODE

ON TIME

OFF TIME

Power 0(P-HI)

32 sec.

0 sec.

(00% power)

Power 9(P-90)

30 sec.

2 sec.

(approx. 90% power)

Power 8(P-80)

26 sec.

6 sec.

(approx. 80% power)

Power 7(P-70)

24 sec.

8 sec.

(approx. 70% power)

Power 6(P-60)

22 sec.

0 sec.

(approx. 60% power)

Power 5(P-50)

8 sec.

4 sec.

(approx. 50% power)

Power 4(P-40)

6 sec.

6 sec.

(approx. 40% power)

Power 3(P-30)

2 sec.

20 sec.

(approx. 30% power)

Power 2(P-20)

8 sec.

24 sec.

(approx. 20% power)

Power (P-0)

6 sec.

26 sec.

(approx. 0% power)

Power 0(P-0)

0 sec.

32 sec.

(0% power)

Note: The ON/OFF time ratio does not correspond with the

percentage of microwave power, because approx. 2

seconds are needed for heating of the magnetron

filament.