4

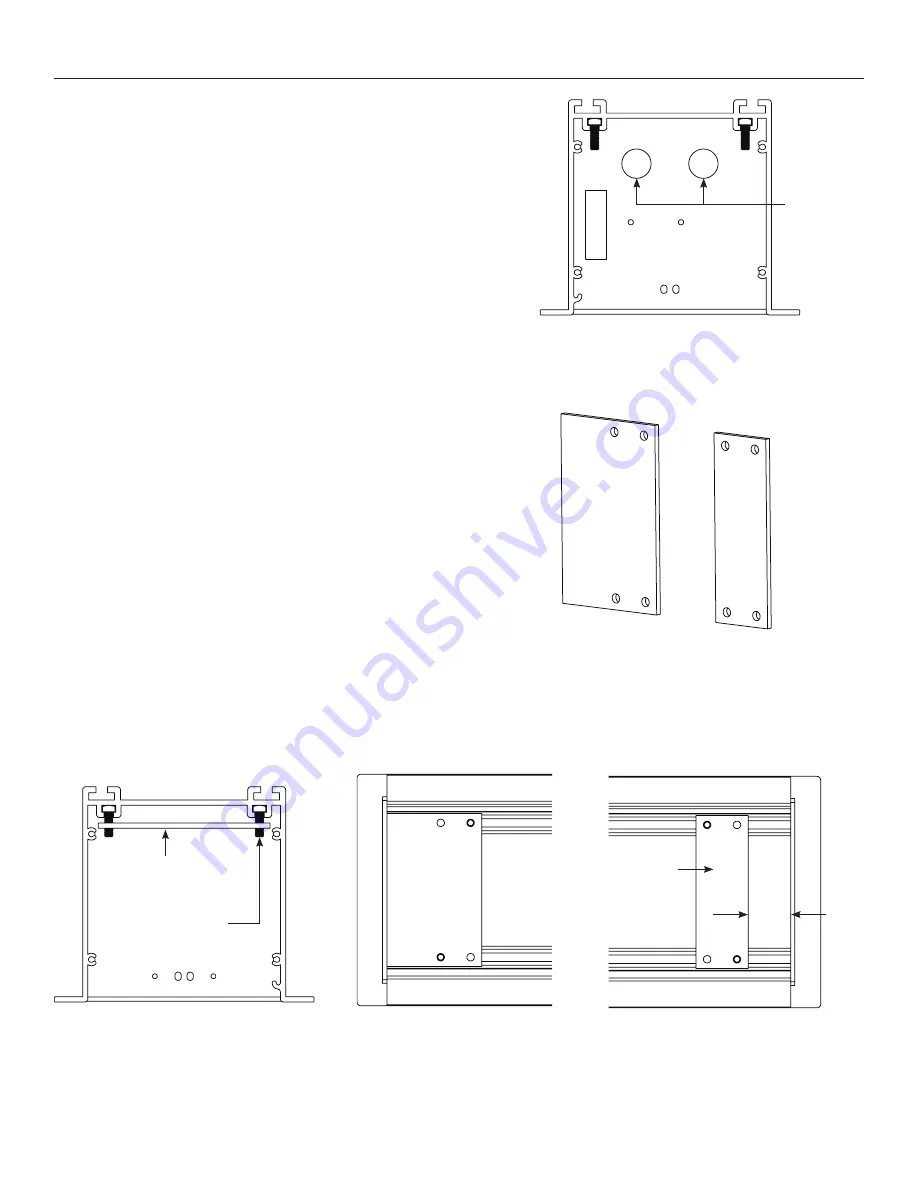

Pre-Installation of ViewShare Screen and Roller Assembly

1. Remove existing motor and pin end roller assembly brackets

from inside the case.

NOTE:

At this point the inside of case will be empty except for

the junction box connections on the motor end.

2. Remove a single circular knockout from motor end of case for

CAT5 cable needed in the Installation of ViewShare Screen and

Roller Assembly (Figure 4).

NOTE:

The CAT5 cable should be run from the Local CAT5 to

USB Extender in Camera and Speakerphone Installation to this

location. Final connection of this CAT5 cable running through the

knockout will occur in Step 10 of Installation of ViewShare Screen

and Roller Assembly.

3. Place the two spacing gaskets (shown in Figure 5) on the bracket

bolts with 1/4” – ½” of the bolts showing through the bottom

(Figure 6).

4. Slide the motor end spacing gasket until it makes contact with

the end of the case (Figure 7).

5. Slide the pin end spacing gasket until it is approximately 1 ½

inches from the end of the case (Figure 8).

6. Carefully unpack the new ViewShare screen and roller assembly

and set aside. Be sure to leave the packing paper on the roller.

NOTE:

If your screen and roller assembly was ordered with a

new motor, please proceed to “Installation of ViewShare Screen

and Roller Assembly”. If you are utilizing your existing motor,

please continue to “Transfer of Existing Motor”.

Figure 4

Figure 5 – Spacing Gaskets

Figure 6

Figure 7

Figure 8

Circular

Knockouts

for CAT5

Cable

Spacing

Gasket

1/4" to 1/2" of

bolt showing

Motor End

Gasket

Motor End

Spacing

Gasket

Pin End

Spacing

Gasket

1 ½ in.

Pin End

Gasket

Summary of Contents for ViewShare Tensioned Advantage Electrol...

Page 1: ...INSTRUCTION BOOK FOR ViewShare Tensioned Advantage Electrol Retrofit...

Page 18: ...18...

Page 19: ...19...