PRE-INSTALLATION

1

INSTALLATION

1. Install screen by raising unit into position between joists at one end only. Install lag screws in mounting bracket or

hang from 3/8" rods.

2. Level unit lengthwise with a carpenter’s level and plumb level. Secure opposite end.

CAUTION! Do not secure access door or seal in until screen has been secured in position and properly tested for satisfactory

operation.

3. Remove screw at each end of roller access door (Fig. 1).

4. Remove junction box cover plate.

If your screen has the low voltage control built-in, remove access cover on right end of case. See Figure 3.

5. Install electric hook up that applies to your unit. Make sure to review your electrical installation checklist and wiring

diagram (included) for either 120 volt switch, 220/240 volt switch, or DRC low voltage control.

NOTE: Screen has been internally wired at Da-Lite. Wiring designated “external” is completed by installer conforming to local

and national codes.

CAUTION! DO NOT CUT TAPE ON FABRIC WITH A KNIFE OR ANY SHARP TOOL. REMOVE BY HAND.

▲

!

1. Carefully unpack screen and remove outer wrapping from case.

2. Make sure to recheck measurements of screen location before installation.

▲

!

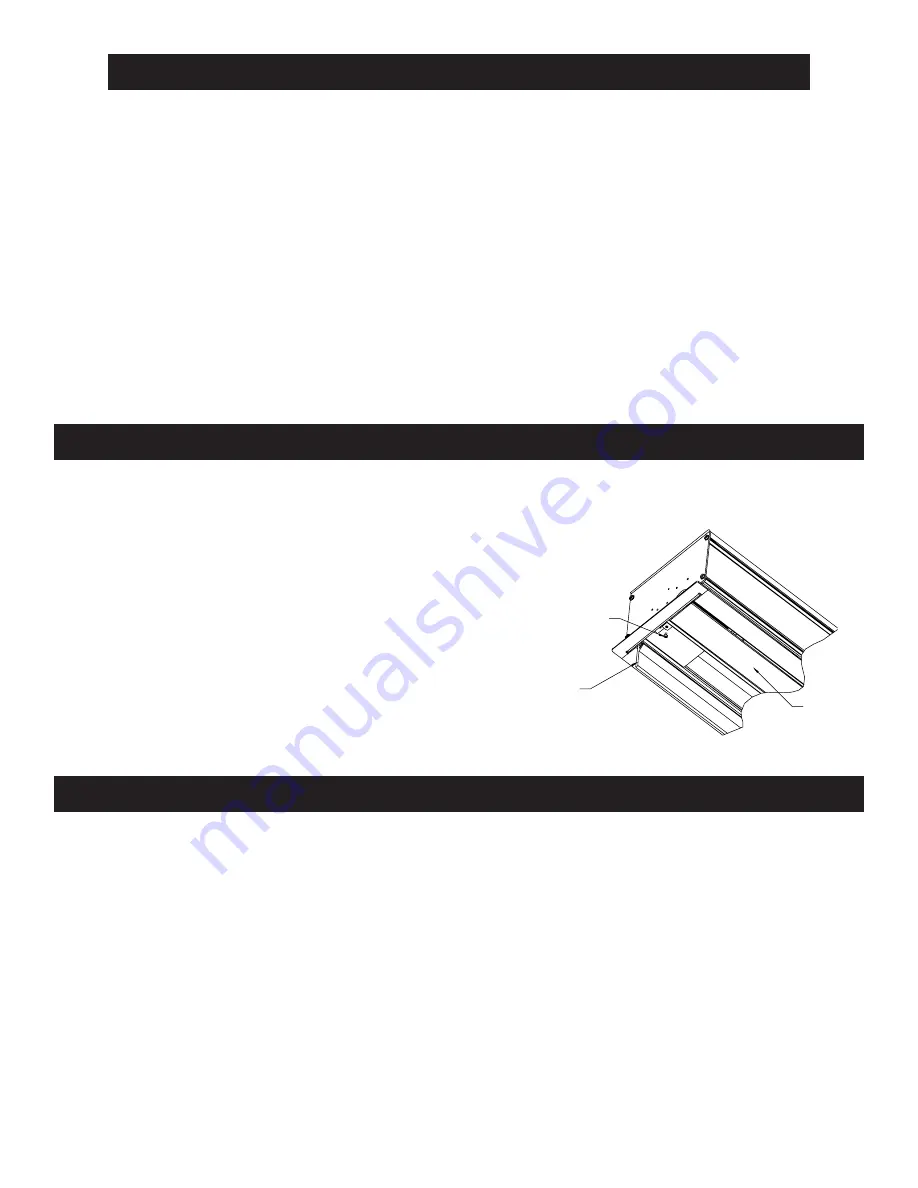

FABRIC DOOR

ACCESS

DOOR

SCREW FOR

SECURING ROLLER

ACCESS DOOR

FIGURE 1

IMPORTANT SAFETY INSTRUCTIONS

When using your video equipment, basic safety precautions should always be followed, including the

following:

1. Read and understand all instructions before using.

2. Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

3. If an extension cord is necessary, a cord with a current rating at least equal to that of the appliance

should be used. Cords rated for less amperage than the appliance may overheat.

4. To reduce the risk of electric shock, do not disassemble this appliance. Contact an authorized

service dealer when repair work is required. Incorrect reassembly can cause electric shock when

the appliance is used subsequently.

5. The use of an accessory attachment not recommended by the manufacturer may cause a risk of

fire, electric shock, or injury to persons.

SAVE THESE INSTRUCTIONS