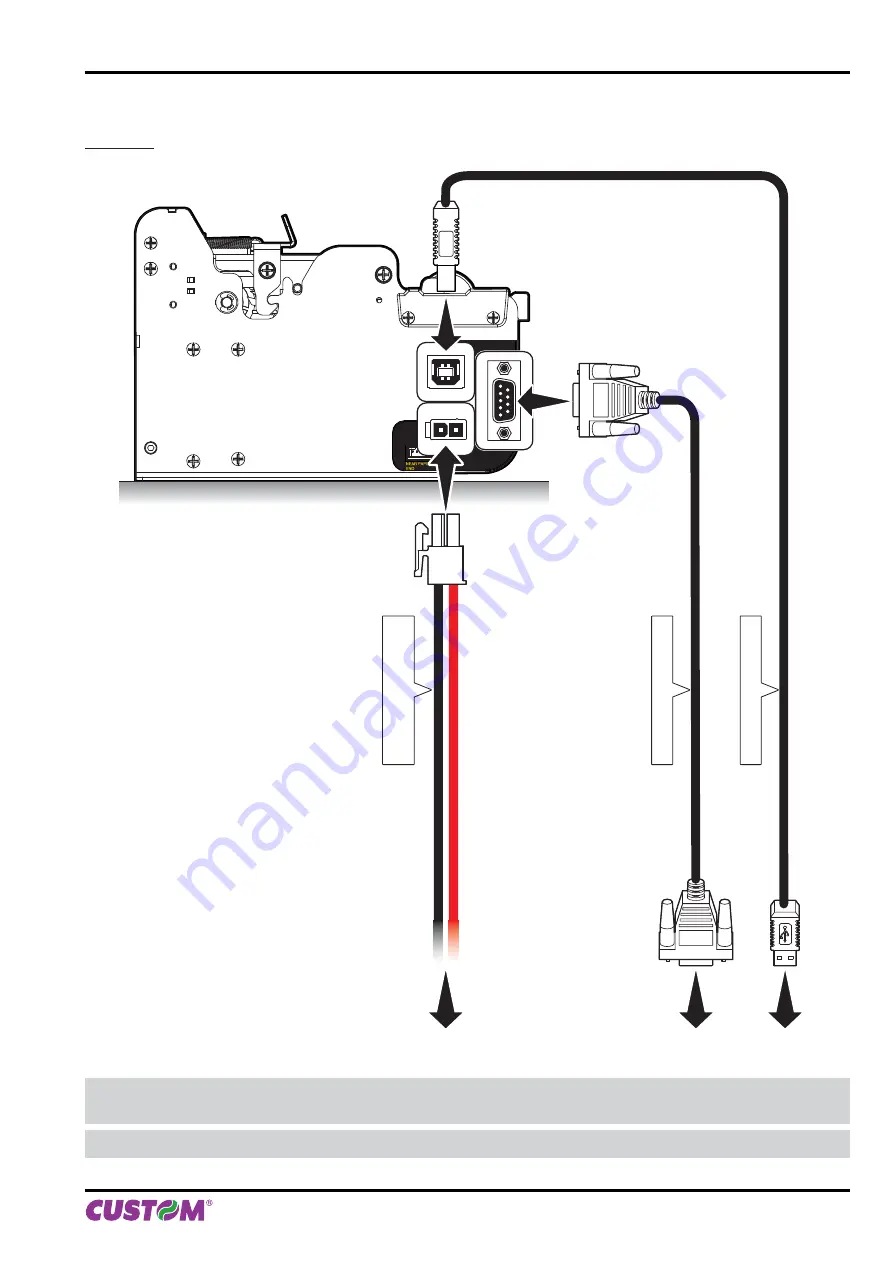

3.3 Connections

KPM150H

RS232

POWER SUPPLY

USB

Serial standard cable

USB standard cable

Power Supply cable

(supplied)

WARNING: In some using conditions, we recommend the installation of a ferrite core on the power supply

cable and on the serial cable.

NOTE:

If RS232 and USB connectors are inserted, communication port is USB.

3. INSTALLATION

User manual

KPM150H-AERO 29

Summary of Contents for B202H

Page 1: ...OEM AIRPORT KPM150H KPM150H B202H B202H USER MANUAL...

Page 2: ......

Page 4: ......

Page 8: ...1 INTRODUCTION 8 KPM150H AERO User manual...

Page 24: ...2 DESCRIPTION 24 KPM150H AERO User manual...

Page 54: ...4 OPERATION 54 KPM150H AERO User manual...

Page 66: ...5 CONFIGURATION 66 KPM150H AERO User manual...

Page 80: ...6 MAINTENANCE 80 KPM150H AERO User manual...

Page 98: ...8 ACCESSORIES 98 KPM150H AERO User manual...

Page 108: ...11 ADVANCED FUNCTIONS 108 KPM150H AERO User manual...

Page 109: ......

Page 110: ......

Page 111: ......