19

S

ection

5 — P

roduct

c

are

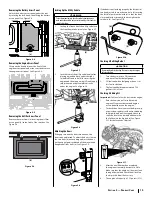

Cleaning Primary Air Filter Element

Open the air cleaner cover once a week under

ordinary conditions — or daily when used in a dusty

place — to get rid of large particles of dust and dirt.

Note:

Do not run the engine with filter element

removed.

1.

Remove the air filter access panel.

2.

Remove the air filter cover (a) from the three

air filter cover holders (b). See Figure 5-25.

(a)

(b)

(b)

(b)

Figure 5-25

3.

Remove the air filter element. See Figure 5-26.

Figure 5-26

4.

Remove the inner filter (a) from the paper

element (b). See Figure 5-27.

(a)

(b)

Figure 5-27

5.

Clean the paper element with a soft brush

or low pressure air. Be careful not to

damage the paper pleats during cleaning.

6.

Inspect the inner filter for deposits or damage.

7.

If either filter are excessively dirty or

damage replace filters as a set.

8.

Re-install the primary air filter element.

9.

Install the air filter case cover and be sure

the crankcase breather hose is connected.

Note:

Be sure to refit the air filter cover with

the arrow (on the rear of air filter cover)

upright. If the air filter cover is improperly

fitted the evacuator valve will not function

and dust will adhere to the air filter element.

Cleaning the Air Intake

Air Intake Screen

1.

Remove the hood and locate the air intake.

2.

Remove the rubber seal (b) around the front

of the air intake (a) and remove the air intake

screen (c). See Figure 5-28.

(a)

(b)

(c)

Figure 5-28

3.

Rinse the air intake screen (c) with water and

replace the air intake screen (c) and rubber

seal (b). See Figure 5-28.

Drain the Air Intake

1.

Remove the nine Allen-head bolts (a) and

washers (a) securing the middle skid plate

to the bottom of the utility vehicle. See

Figure 5-29.

(a)

(a)

(a)

(a)

(a)

(a)

(a)

(a)

(a)

Figure 5-29

2.

Remove the drain and allow the water to run

out. Then replace the drain and the middle

skid plate. See Figure 5-29.

(a)

Figure 5-30

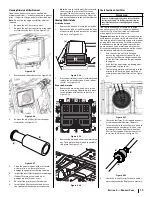

Check Fuel Line & Fuel Filter

WARNING

Be sure to stop the engine and remove the key. Check the

fuel lines periodically. The fuel lines are subject to wear

and old fuel may leak onto a running engine which may

cause a fire.

The fuel line connections should be checked

annually or every 100 service hours whichever

comes first. The fuel line is made of rubber and

wears regardless of service period.

Important:

When the fuel line is disconnected for

maintenance or repair, close both ends of the fuel

line with a piece of clean cloth or paper to prevent

dust and dirt from entering. Particular care must

be taken not to allow dust and dirt into the fuel

pump entrance. Even a small amount of dust or

dirt cause premature wear and the malfunction of

the fuel pump and injector components.

1.

Park the vehicle on a flat surface and

remove the engine access panel. There is

a primary fuel filter on the gas tank and an

in-line fuel filter between the gas tank and

the engine.

2.

If the fuel line and clamps are damaged or

deteriorated, replace them.

3.

There are two main lines (a) coming into the

primary fuel filter (b) and one main line (c)

exiting the primary fuel filter (b). See Figure

5-31.

(a)

(b)

(a)

(c)

Figure 5-31

4.

Check the fuel filter if it is clogged by debris

or contaminated with water, replace it.

5.

To remove the in-line fuel filter, use pliers to

squeeze tabs on the clamps (b), then slide

the clamps (b) away from the in-line fuel

filter (a). Twist and pull the fuel lines off of

the in-line fuel filter (a). See Figure 5-32.

(a)

(b)

(b)

Figure 5-32

6.

Check the in-line filter (a) for debris and/or

water contamination. Replace as necessary.