9

9

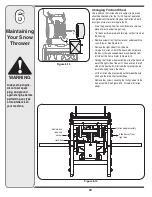

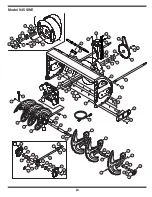

Parts List

REF

NO.

PART

NUMBER

DESCRIPTION

1

05244B

Housing, Bearing

2

618-0279

Dogg, Steering Drive, LH

3

618-0280

Dogg, Steering Drive, RH

4

618-0282E

Shaft Assembly, Steering

5

618-04178

Assembly, Friction Wheel

718-04034

Wheel, Friction, Bonded

710-0896

Screw, Hex Wash

6

684-0118A

Bracket, Auger Actuator

7

684-0119A

Bracket, Drive Actuator

8

684-04235

Sprocket, 32T

9

684-0161

Arm, Shift

10

684-04212

Brkt, Friction Drive Suprt.

11

684-04103

Rod Assembly, Shift

12

784-0385B

Brkt., Idler, Auger

13

710-0538

Screw, Hex Cap Lock,

14

756-0178

Idler, Flat, 2.75 OD

15

754-0222A

V-Belt, 1/2 x 44.0

16

750-04718

Spcr., .51 ID x 3.66 Lg.

17

710-1652

Screw, Hex Wash.

18

750-04717

Spcr., .51 ID x 7.895 Lg.

19

710-3001

Screw, Hex Cap, 3/8-16

20

750-04703

Spcr., 1.0 ID x 1.50 OD

21

710-0788

Screw, Hex, 1/4-20 x 1.00

22

710-0459A

Screw, 3/8-24 x 1.50

23

711-04279

Shaft, Hex Drive

24

711-04605

Shaft, Actuator

25

716-04048

Ring, Retainer

26

712-0116

Nut, Hex Insert Jam Lock

27

712-0138

Nut, Hex, 1/4-28 GR5

28

784-5726

Bracket, Idler, Drive

29

712-04065

Nut, Hx Flnge Insert Lk

30

712-0413

Nut, Hx Insert Jam Lk

31

710-04484

TT Screw, 5/16-18 x .750

32

712-0717

Nut, Insert 3/8-16

33

713-0284

Chain, Endless, #41 x 36L

34

713-0286

Chain, #420 x 40L

35

713-04015

Sprocket, #41 x 10T

36

714-0135

Key, Woodruff

37

714-0104

Pin, Internal Cotter

38

716-0104

E-Ring

39

714-0388

Key, Hi-Pro, 3/16 x 5/8

40

716-0136

Ring, Retaining

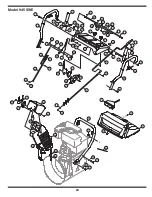

REF

NO.

PART

NUMBER

DESCRIPTION

41

717-0302

Plate, Drive

42

732-0121

Spring, Extension

43

732-0209

Spring, Extension

44

756-0241B

Pulley, Dbl, 3.25 OD

45

736-0158

Washer, Lock, 5/8

46

756-0240

Pulley, Flat Idler, 3.0 OD

47

634-0225

Wheel Ass’y. - LH

634-0226

Wheel Ass’y. - RH

734-2031

Tire

734-0255

Valve

741-0246A

Bearing

48

711-04615

Pin, Clevis

49

736-0242

Wsh, Bell., .34 x .872 x .06

50

736-0300

Wash, .406 x .875 x .059

51

736-0329

Washer, Lock, 1/4

52

714-0149B

Pin, Internal Cotter

53

737-3000

Fitting, Lube, 3/16 Drive

54

738-0143

Screw, Shldr., .498 x .34

55

738-0279

Spindle, Drive Plate

56

738-0924A

Screw, Hex Shldr., 1/4-28

57

741-0163A

Ass’y, Bearing/Housing

58

741-04108

Bearing, Hex Flange

59

741-04025

Bearing, Self Aligning

60

741-04076

Bearing, Ball

61

741-0563

Bearing, Ball

62

741-0748

Bush, Flg, .5 ID x .627 OD

63

746-0949A

Cable, Steering

64

746-0951

Cable, Auger Idler

65

747-0973

Rod, Drive Clutch

66

750-0903B

Spcr., .514 x .632 x 2.44

67

750-0997

Spacer, .675 x 1.0 x .23

68

750-1302B

Spcr, .6725 x 1.125 x 2.48

69

756-0344

Pulley, Drive

70

756-0625

Roller, Cable

71

790-00257

Cover, Upper Frame

72

790-00259

Cover, Lower Frame

73

711-04606

Axle, Wheel

74

790-00255

Frame, Transmission

75

784-0406A

Bracket, Frame Support

76

784-0407

Bracket, Axle Support

77

790-00254

Bracket, Belt Cover

78

710-0191

Screw, 3/8-14 x 1.25 GR8

To order replacement

parts, call the Customer

Dealer Referral Line at

1-877-282-8684,

or visit

www.cubcadet.com to

find the nearest Cub

Cadet service dealer in

your area.

G

E N U I N E

FA

CTO

RY PAR

TS

Continued on following page