www.cs-lab.eu

CS-Lab s.c. | CSMIO/IP-A 6-axis CNC controller. Manual tunning

16

4)

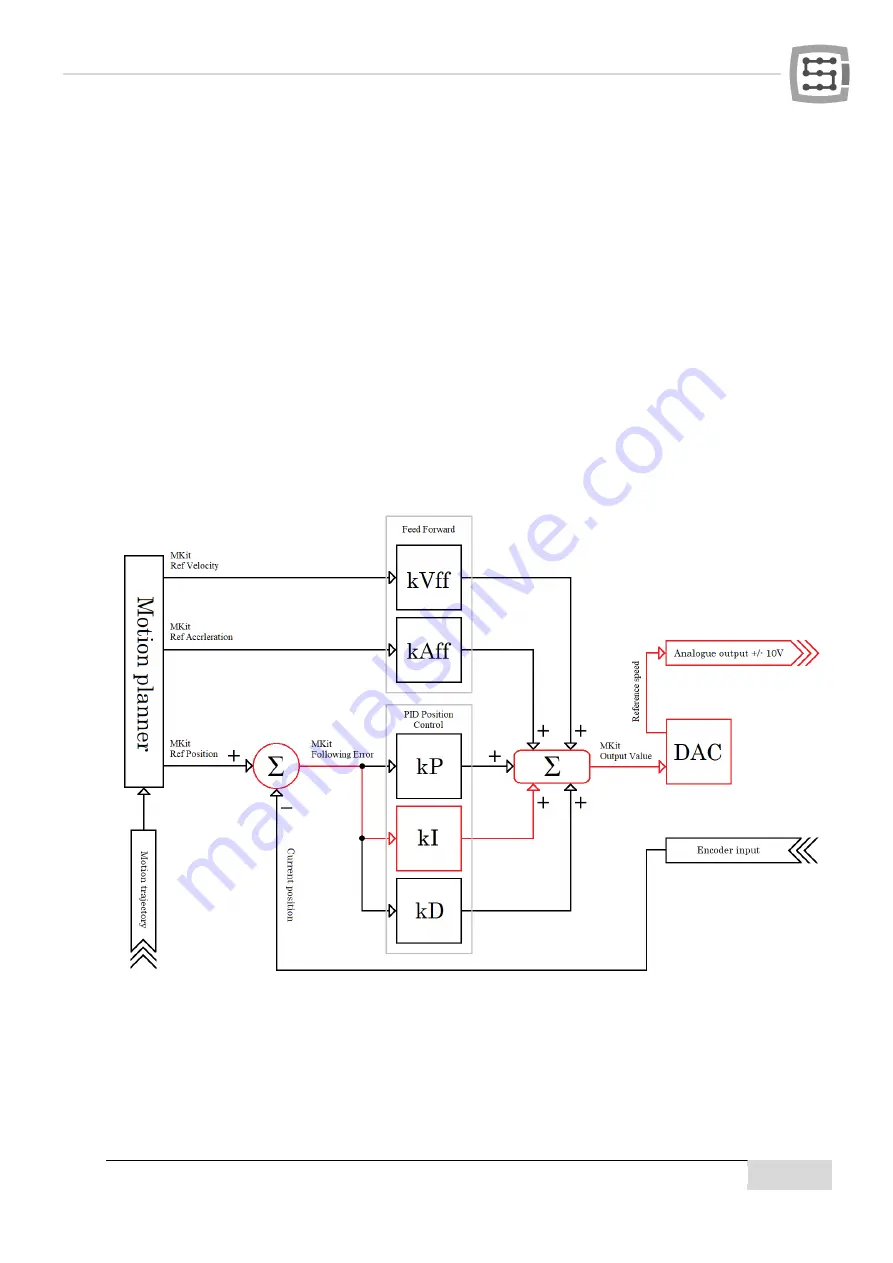

The next stage is to find the correct value of the "kI" parameter. It's used in situations when the servo

drive velocity PID regulator doesn't have an integral term or does not fulfill its task sufficiently due to the

servo drive's outdated design.

Increase the "kI" parameter as long as the "Mkit Following Error" value decreases and axis oscillations

aren't noticeable.

•

A too high value of the "kI" causes the integral term of position PID regulator reacts to "Mkit Follow-

ing Error" value much faster and harder than a servo drive can provide what causes the before men-

tioned axis oscillation.

•

A too low value of "kI" parameter causes the integral term of position PID regulator reacts too slow

and weak on the "Mkit Following Error" value what translates into an unnecessarily high value of

"Mkit Following Error".

The "kI" is a value of integral term gain of position PID regulator. In simplification, the higher "kI" and "Mkit

Following Error" value and the longer the value lasts, the higher voltage value will go to the +/-10V analog

output of a CSMIO/IP-A controller.