Routine

Maintenance

- 35 -

Using skills

Change

Fuse

Open fuse tray

Change

new

fuse

1

.

Frequent

cleaning

stains

on

the

rail

.

2

.

Lubricate

the

four guide rail.

3

.

Frequent cleaning feeder gear.

Notice: Don’t add too much lubricating

oil.

Print Setting

Of

Different Filament

*

The

data

is

only

for

reference, different environmental data will be different.F160 and F430 can print PEEK.

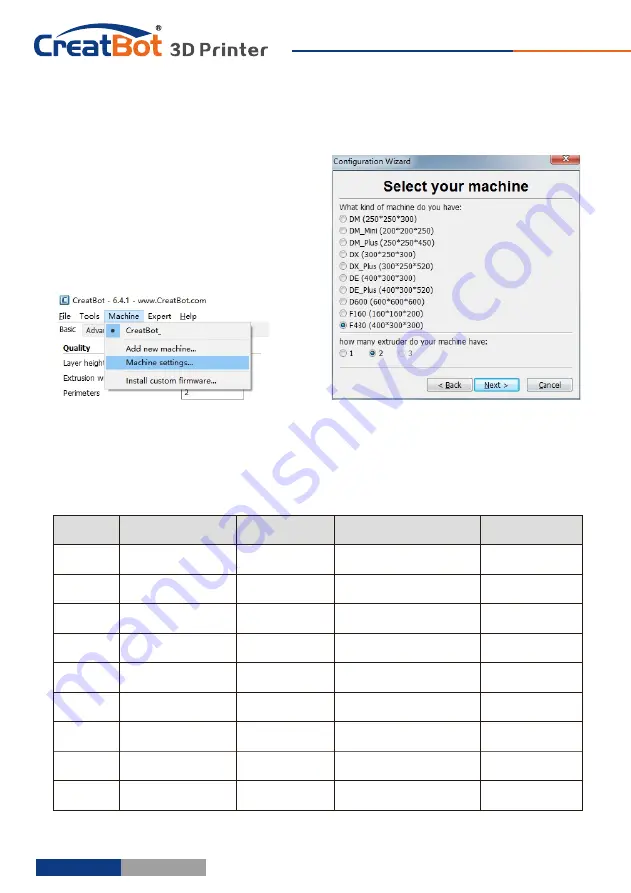

Add

Multi

Type

Printer

You

can

add

more

than

one

type

of

CreatBot

to

the

software, and easily

switch between them without re-config

all the different machine settings.

- 34 -

F430

Nozzle temperature

Hot bed

Plantform adhesion type

Fully enclose or

not

PLA

190~210

℃

N

one

/45℃

None/Raft

Can

open

ABS

240~250

℃

90 ℃

B

rim

/R

aft

Enclosed

Nylon

240~270

℃

100

℃

B

rim

/

R

aft

Enclosed

HIPS

230~260

℃

100

℃

N

one

/

Brim

Enclosed

PETG

230~260

℃

100

℃

N

one

/

B

rim

Enclosed

Flexible

210~230

℃

N

one/45

℃

N

one

Can

open

Wood

190~220

℃

N

one

/

45

℃

N

one

Can

open

PC

230

~

260

℃

100

℃

B

rim

Enclosed

PEEK

380~430

℃

Bed

120 ℃ /

Air 70

℃

Raft

Enclosed

Software

Operation

Using skills