4

、

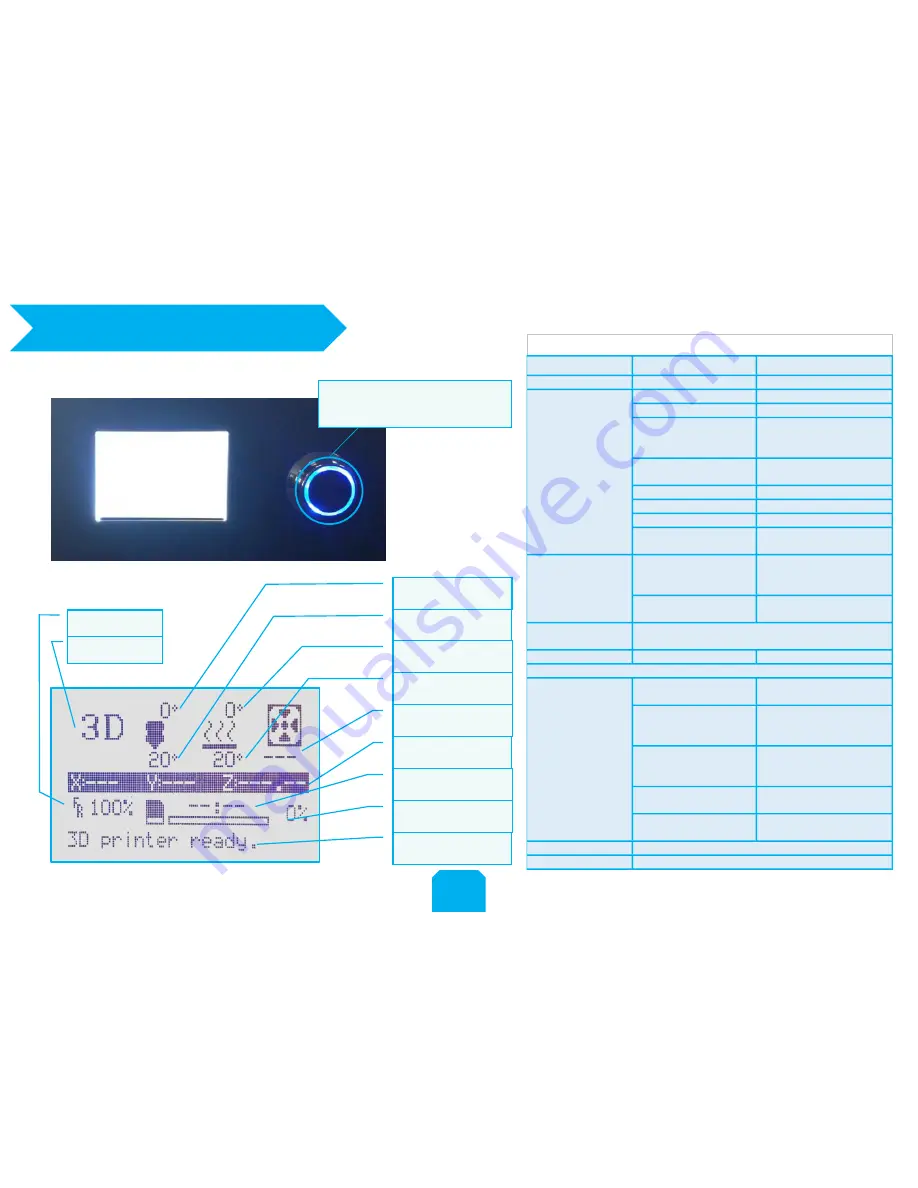

LCD Menu

5

Set temperature of the

Nozzle

Current temperature of

the Nozzle

Set temperature of the

Hot Bed

Current temperature of

the Hot Bed

Part Cooling Fan Speed

Current location of the

nozzle

Print time

Print progress

Prompt message

Print speed

Model

Push

:

OK/Enter Sub Menu

Turn

:

Change Option/Value

Information Displayed

Screen Options

Menu

Sub Menu

Explanation

Ė

Info Screen

Ė

Ė

main

Ė

Return

Prepare

ė

Auto Home

return to the origin

Bed Auto Leveling

ė

Move Axis

ė

Moving X Y Z axis or

Extruder by given

value.

Disable Steppers

Moving X Y Z axis by

your hands

Change filament

Load/Unload filament

Preheat PLA

Preheat ABS

Cooldown

Close and cooldown

the nozzle

Control

ė

Temperature

ė

Heat the nozzle and

the bed or change fan

speed by given value

Restore Failsafe

Restore factory

setting

No card

/Print from SD

LED Control

Pringting

Tune

ė

Speed

Change Printing Speed

by given value

Nozzle

Change the

temperature by given

value

Bed

Change the

temperature by given

value

Fan Speed

Change Fan Speed by

given value

Flow

Change filament flow

by given value

Pause Print

Stop Print

Select the printing model

ON/OFF

Summary of Contents for CR-2020

Page 6: ...1 2 3 4 1 2 3 3 Assembly ...

Page 7: ...4 3 4 How to start 1 Open the power switch 2 Open the Start switch ...

Page 10: ...5 Change Filament 7 Load Filament ...

Page 11: ...7 Unload Filament ...

Page 12: ...7 Software Installation 8 ...

Page 13: ...8 Preparing to Print 9 ...

Page 14: ...9 Trouble shooting 10 ...