4

REASSEMBLY

Reassembly will generally be in reverse order of

disassembly. If disassembly was not complete, use only

those steps related to your particular repair program.

1.

The sleeve must be checked for abrasion, damage

during disassembly, or corrosion that can occur

when

fl uid residue penetrates between the seal (80)

and sleeve (14). The sleeve under the seal should

be lightly polished to a 32 RMS fi nish before

reassembly.

Do not

reuse a pitted or damaged

sleeve. Slide the sleeve (14) on the motor shaft (6).

2.

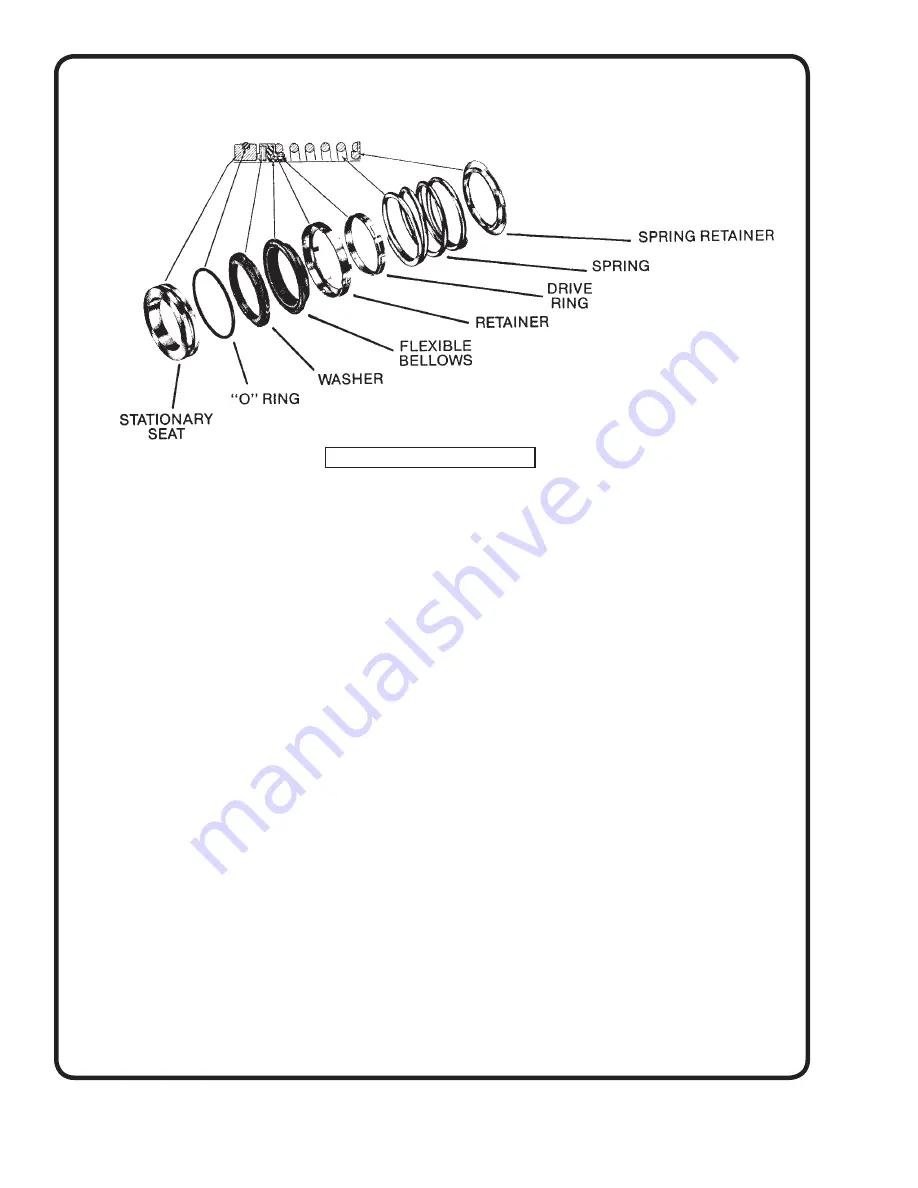

The mechanical seal (80) (See Figure 2) cannot be

installed as an assembly. It is necessary to have the

seal seat properly in place before the balance of

parts can be added. Thoroughly inspect the seal

cavity in the bracket for burrs or nicks which could

damage the seat of the seal. Apply a fi lm of soap

paste

or

fl ax soap

(Do not use oil or grease)

to

the seal seat and install, taking care to seat it evenly

and

squarely.

NOTE:

If it is not possible to insert seal with fi ngers, place

cardboard protecting ring furnished with seal over lapped

face of seat and press into place with a piece of tubing

having end cut square. The tubing should be slightly larger

than diameter of the shaft. Remove cardboard after seat is

fi rmly in place.

3.

Position casing cover (11) on the motor and secure

with capscrews (83). Tighten screws evenly to

assure proper alignment.

4.

Wipe the sealing faces of the seat and seal washer

clean. Oil these surfaces with a clean light oil. Lightly

oil the shaft sleeve (14). Slide the entire mechanical

seal rotating assembly onto the sleeve.

5.

Press wearing rings (25) and (27) into the casing

(1) and casing cover (11). Rings should not be

hammered into place. Use a press, or clamp the

parts in a bench wise, using wooden blocks to

protect the rings. It may be necessary to pin or

dowel the rings after assembly if the insert or casing

has had rings replaced before, since each

reassembly can stretch or tear metal and thereby

loosen

the

fi ts.

6.

Assemble key (32) and impeller (2) to motor shaft.

Secure impeller (2) to motor shaft. Secure impeller

(2) with washer (28) and impeller screw (26).

7.

Install all drain plugs in the casing. Position the

gasket (73) and casing (1) against the casing cover

(11) and secure with screws (82).

8. Repalce

all

fl ushing or drain lines. Connect

discharge piping and suction piping if required,

making sure to install gaskets on the fl anged

connections. Connect electric power to motor.

STARTING PUMP AFTER REASSEMBLY

Do not pump until all air and vapor has been bled. Make

sure that there is liquid in the pump to provide the neces-

sary lubrication, (Without the fl uid around it, the seal may

be ruined in a few seconds of operation). It is possible that

the mechanical seal may drip during the fi rst few minutes

to one hour of operation.

Figure 2 - MECHANICAL SEAL

Summary of Contents for WEINMAN 6012CV

Page 8: ...Notes ...