8

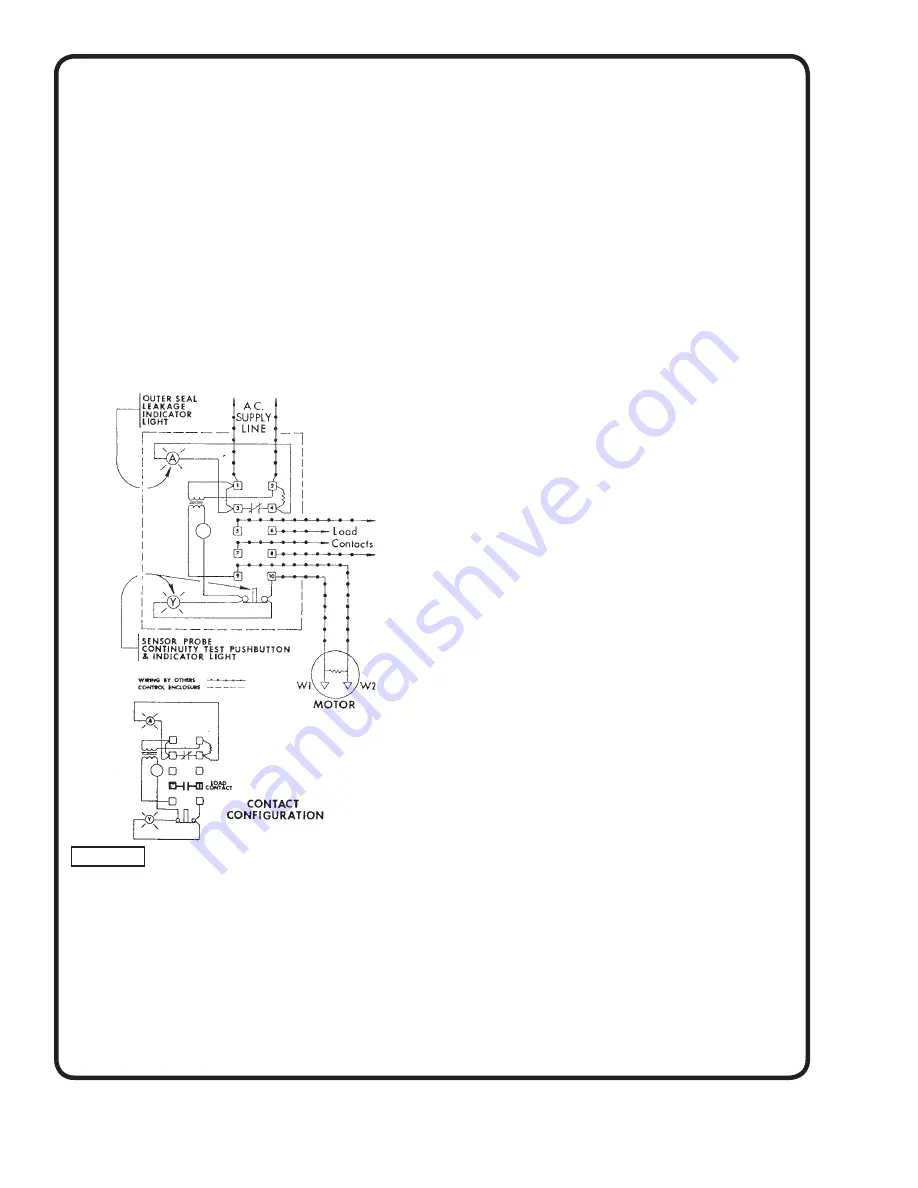

MOISTURE SENSING RELAY

Moisture sensing replay is a conductance actuated control

for detecting moisture in the oil chamber of a submersible

motor. It is used as a warning device to indicate a

seal leakage and to signal the need for preventive

maintenance.

Mount the control box vertically on a wall or other solid

structure and complete all indicated wiring as shown

on the above wiring diagram. Terminals on the control

are numbered, as shown Terminal Pair I and 2 must be

continuously energized from an AC supply line of the correct

voltage as shown on the control data plate. Contacts 5 and

6 or 7 and 8 are available for connecting audible alarm

or light if required and must be wired in series with such

device; and that series branch circuit connected across the

power source compatible with the load. Terminals 9 and 10

are connected to the moisture sensing probe in the motors

marked WI and W2 by means of the cable provided with

the motor. See Figure 5.

OPERATION

Normally the oil surrounding the probes is non-conductive

and the control and seal leakage indicator light will be de-

energized. An infl ux of moisture past the outer seal and into

the oil reservoir will change the conductivity of the oil and

this condition will cause the relay to energize and the seal

leakage light and/or alarm will energize to indicate a seal

leakage. Load contacts 5 and 6 or 7 and 8 will also change

from their normally open position to a closed position when

the control energizes.

TEST PROCEDURES

A normally closed push-button and neon indicating

light are provided as a part of the control for testing the

moisture sensing components. The motor manufacturer

has provided a resistor across the probes inside the motor

to complete the test. When the test button is depressed

the neon indicating lamp and alarm if installed will be

activated to indicate:

A) Power is supplied to the control;

B) Control is operative;

C) The wiring to the moisture sensing probe in the

motor is intact.

This check does not stimulate a seal leakage, but indicates

that the circuit is operative should a leak occur.

Caution: The voltage will be present at all terminals on

the control when this test is being made.

LIQUID LEVEL CONTROL SYSTEM

A liquid level control system, to automatically start and

stop the pump(s), such as fl oat switch, mercury switches,

such as Deming Fig. 1601, or electrode probes with proper

relay must be installed with the pump. The actuating switch

for such controls is connected in the control circuit of the

magnetic starter.

Liquid level controls must be adjusted to stop the motor if

liquid level in the sump lowers to a point uncovering the

motor. If sump is to be drained—that is, motor uncovered—

some means, such as an automatic timing device, must

be used to limit uncovered operation to 10 minutes with

suffi cient time allowed for cooling of the motor before

restarting.

STARTING

On the initial start-up, the motor and pump must be

checked for proper rotation prior to fi nal installation. See

section on “Direction of Rotation”. The motor should under

no conditions be operated for any appreciable length of

time unless submerged in the liquid as indicated above.

OPERATION

After the pump is in position, discharge piping has been

completed and all electrical connections made, the unit

may be started as follow’s:

1.

Adjust liquid level controls. Make certain that the

controls will stop the pump when the liquid level

reaches the level shown on the Dimension Print on

Page 3. This minimum level is for continuous

operation and results in the motor being completely

submerged at all times.

2.

Open discharge valve, if used.

3.

Allow liquid to enter sump or pit.

4.

Energize motor, either by automatic control device or

manually.

5.

Check liquid level operation as described in Step #1.

Figure 5