4

A - GENERAL INFORMATION

TO THE PURCHASER:

Congratulations! You are the owner of one of the

fi

nest

pumps on the market today. These pumps are products

engineered and manufactured of high quality components.

With years of pump building experience along with a

continuing quality assurance program combine to produce

a pump which will stand up to the toughest applications.

Check local codes and requirements before installation.

Servicing should be performed by knowledgeable pump

service contractors or authorized service stations.

RECEIVING:

Upon receiving the pump, it should be inspected for

damage or shortages. If damage has occurred,

fi

le a claim

immediately with the company that delivered the pump.

If the manual is removed from the crating, do not lose or

misplace.

STORAGE:

Short Term -

Pumps are manufactured for ef

fi

cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as

factory assembled, in a dry atmosphere with constant

temperatures for up to six (6) months.

Long Term -

Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained b40 deg. F and

+120 deg. F. Pump should be stored in its original shipping

container and before initial start up, rotate impeller by hand

to assure seal and impeller rotate freely.

SERVICE CENTERS:

For the location of the nearest Deming Service Center,

check your Deming representative or Crane Pumps &

Systems Service Department in Piqua, Ohio, telephone

(937) 778-8947 or Crane Pumps & Systems Canada, Inc.,

Bramton, Ontario, (905) 457-6223.

B - INSTALLATION

Standard pumps are completely assembled, carefully

adjusted and lubricated at the factory before shipment.

1. Carefully lower the pump into position. The base plate

(023) must be level and rest evenly at all points where

it will be bolted. If necessary, use metal shims as

required to level plate.

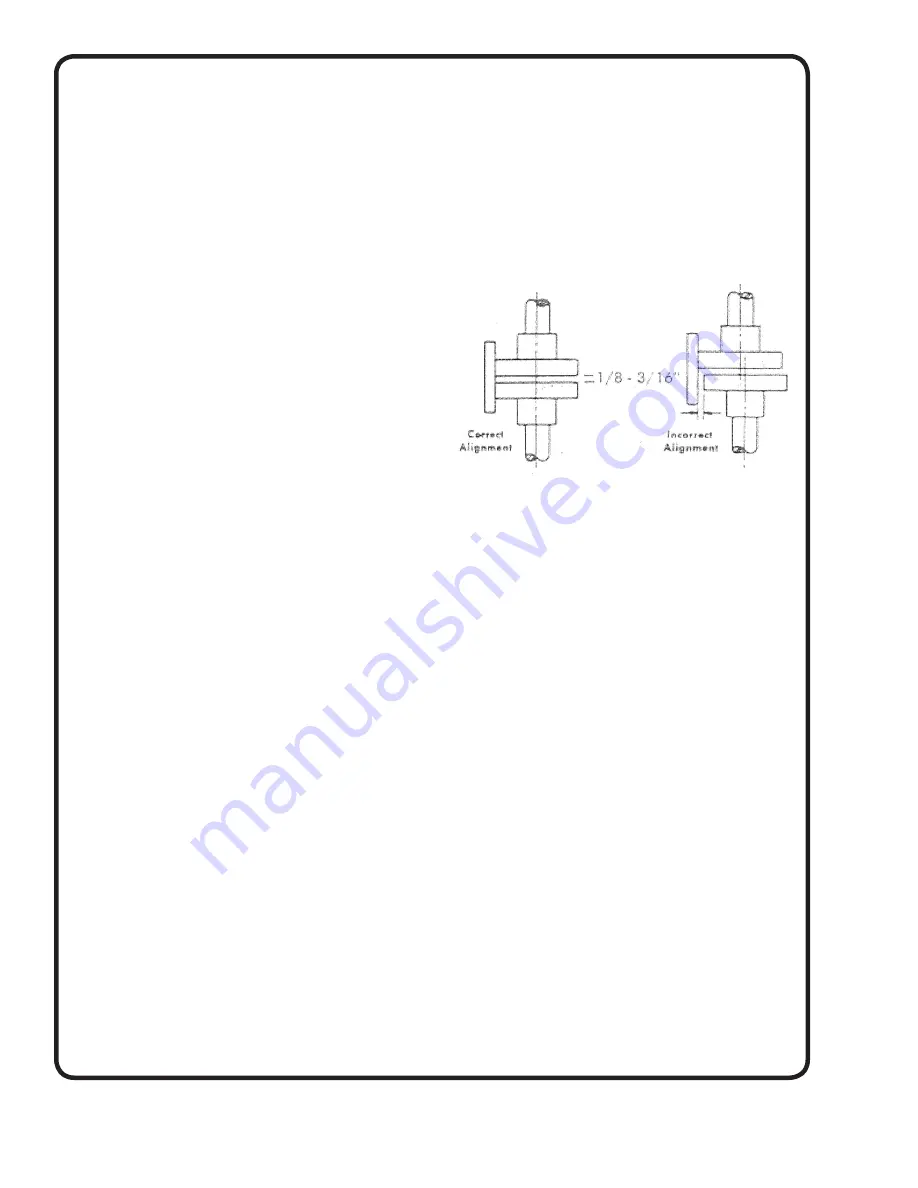

IMPORTANT ! - The alignment between the motor

and pump must be carefully checked before pump is

started.

In spite of careful assembly at the factory, alignment

may change during shipment due to handling. Hold

a straight edge on the coupling so that it extends

over both halves. The straight edge should rest evenly

across both rims of the coupling halves. Any

misalignment may be corrected by adjusting the set

screws in the lugs under the chair bracket, or possibly

metal shims under the motor feet. Chair bracket

mounted units should be checked for alignment every

other day during the

fi

rst week of operation, then once

a week until alignment remains constant.

2. The weight of the suction and discharge pipes and

fi

ttings must be supported independently of the pump

to eliminate any strain on the pump support plate or

pipe. A check valve and gate valve should be installed

in the discharge line close to the pump.

3. Rotate shaft by hand checking for impeller rubbing on

high spots. If either is noted check for (A) pipe strain,

(B) caps misalignment, (C) improper impeller

adjustment.

4. Connect discharge line to pump discharge pipe and

close gate valve. Connect power line to motor in

accordance with wiring diagram on the motor. Jog

motor control to test for rotation, standard pumps

rotate clockwise looking down on the motor. (Left hand

pumps operate in reverse direction.)

5. The pump should operate smoothly. If the pump

vibrates, there is severe distortion of the pump as a

result of excessive installation strain of the support

plate, pipe strain or misalignment between motor and

pump, improper impeller adjustment or a combination

of

these.

C - LUBRICATION

1. Pump bearings are properly lubricated at the factory

before shipment. Periods of subsequent lubrication

depend on local conditions, hours of operation, load,

speed, temperature, etc. It is recommended that

bearings (016) and (018) be periodically inspected and

lubricated.

Summary of Contents for DEMING 5411 Series

Page 7: ...7 ...