4

4. Build a dam around sub-base at least 2” high for

grouting in with thin cement and after cement has

hardened, tighten anchor bolts.

5. Recheck alignment at drive coupling. Any misalignment

now apparent should be corrected by metal shims

under pump or motor. When properly aligned, pump

shaft should turn freely by hand.

6. A foot valve and strainer must be installed on the lower

end of the suction pipe to keep pump completely

fi lled with liquid when the pump is used under suction

lift conditions. Connect suction pipe to pump casing.

When a foot valve is used, it is

absolutely necessary

to install a check valve

in the discharge line near the

pump to prevent possible broken casing due to line

shock or surge when the pump stops. A gate valve

should also be installed in the discharge line. Connect

discharge pipe to pump casing.

It is very important that the suction and discharge pipes

“line up” naturally with the pump. DO NOT “pull” pipes

into position with fl ange bolts. Support pipes

independently of the pump to eliminate all strain on

the pump casing. Select discharge pipe size so velocity

is under 8 feet per second. Avoid sharp changes in

pipe

sizes.

7. After pipes have been connected to pump, check

alignment at drive coupling. Correct any changes with

metal shims as in section “C”.

8. Check motor nameplate for electrical characteristics.

Be sure they are the same as the rating of the electrical

power available. Connect power lines to motor in accord

with wiring diagram on the motor and test motor

rotation, should turn in the direction indicated by arrow

cast on pump casing.

9. Fill pump (and suction pipe) with water. Close discharge

gate valve and start pump. When pump is up to speed,

slowly open the discharge valve to obtain desired

capacity and pressure.

D - LUBRICATION

The ball bearings (16) and (18) are double sealed and

lifetime lubricated by the manufacture before shipment.

Under normal operating conditions no further lubrication

is required. Any motor lubrication should be in accord with

motor manufacturer’s recommendations.

Figure 3

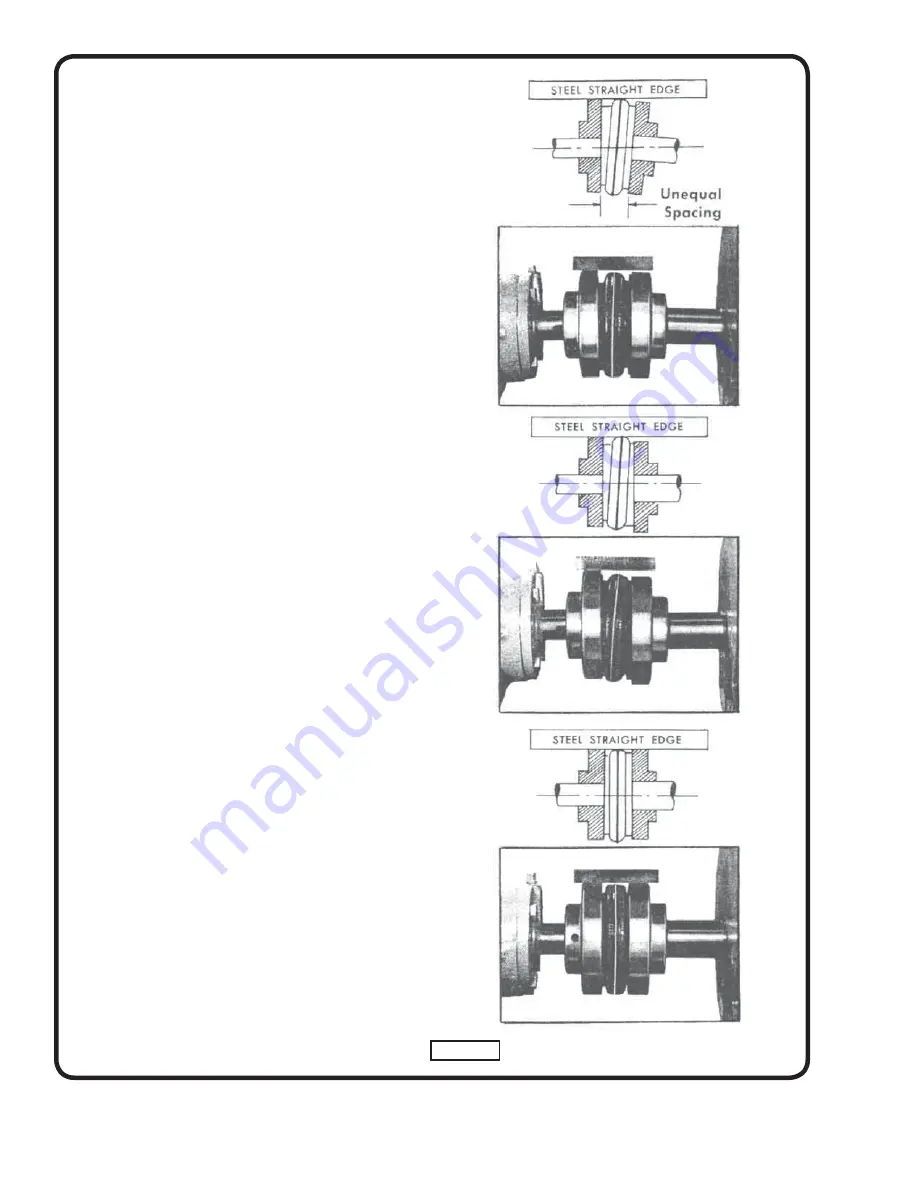

PERFECT

ALIGMENT

PARALLEL

MISALIGNMENT

ANGULAR

MISALIGNMENT

Summary of Contents for Deming 3904 Series

Page 10: ...Notes ...