11

Place all motor leads above motor. Position square ring (42)

on seal plate (25) and lower motor housing (2) over motor

and into pilot. Place socket head cap screws (39) through

seal plate (25) into motor housing (2) and torque to 75

inch pounds. Make wire connections per paragraph F-3.3.

Assemble impeller and volute per paragraph F-2.2.

F-3.3) Wiring Connections:

Check power cords (10) for cracks or damage and replace

if required. Make internal wiring connections which are

independent of the terminal block as shown in (Figure 10),

using connectors (23) and wire assemblies (29) as required.

Do not use wire nuts. Slip motor leads and ground wire

through fi berglass sleeve (22). Lower motor housing (2)

down onto seal plate (25) while aligning holes and stringing

motor leads through the cord entry bore(s). (Slipping cords

inside a 1 ft. length of .5” conduit makes this easier). Place

socket head cap screws (39) through seal plate (25) into

motor housing (2) and torque to 75 in-lbs.

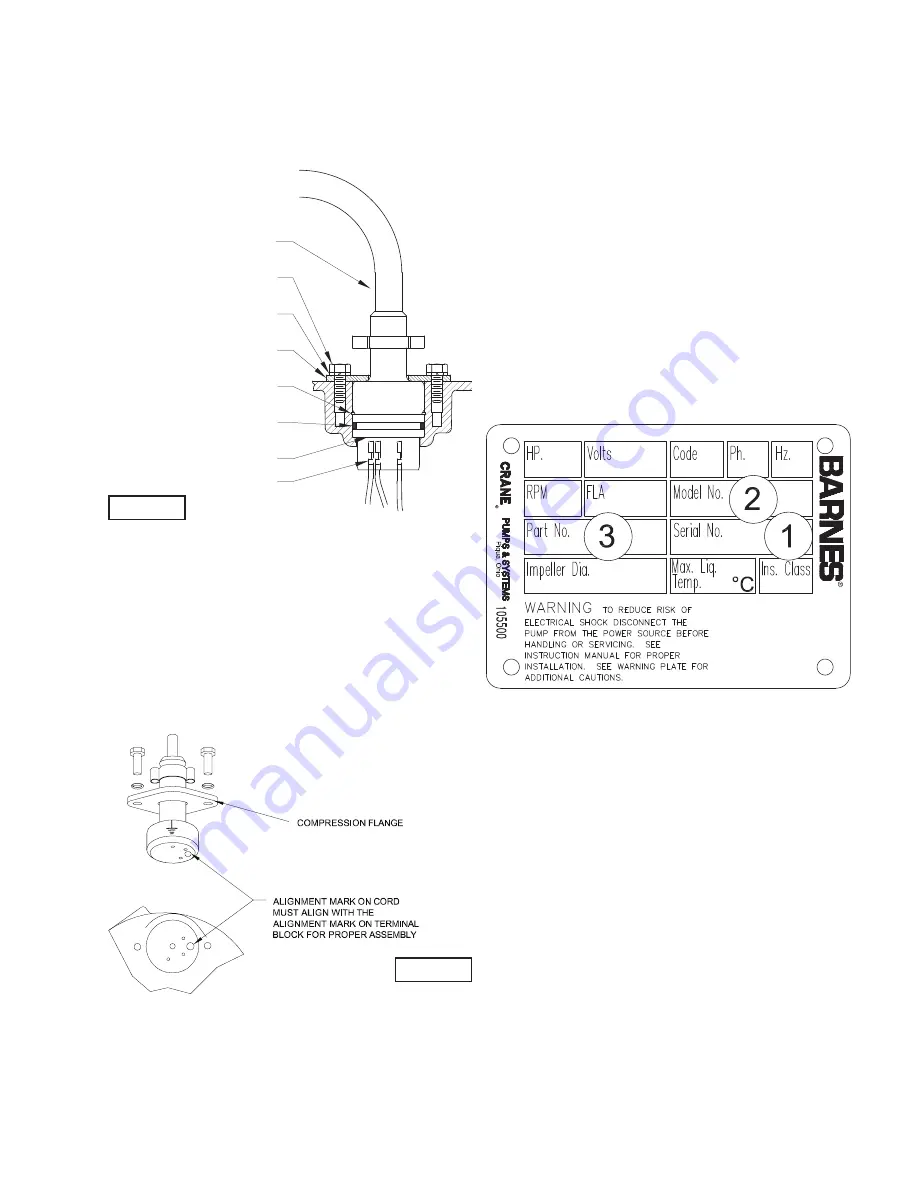

Reconnect motor leads to the underside of the terminal

block(s) (27) as shown in Figure 8. Note that the pins are

numbered underneath the terminal block. Place o-ring (12)

into groove in terminal block (27) and lubricate with dielectric

oil. Press the terminal block (27) into the housing so it seats

completely below the snap ring groove. Place snap ring (8)

into groove in cord entry bore of motor housing (2). Repeat

terminal block installation for sensor cord, if equipped.

F-3.4) Cord Assemblies:

Power -

Refi ll the cooling oil as outlined in paragraph F-1.4.

Make wire connections as outlined in paragraph F-3.3.

Insert female end of cord plug into housing bore aligning

timing mark with hole in terminal block (27) (see Figure

5). Compress cord plug with compression fl ange (10a)

by tightening cap screws (24) into the motor housing (2).

Torque to 132 in-lbs.

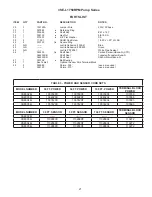

SECTION: G REPLACEMENT PARTS

G-1 ORDERING REPLACEMENT PARTS:

When ordering replacement parts, ALWAYS furnish the

following information:

1. Pump serial number and date code. (Paragraph G-4)

2. Pump model number. (Paragraph G-3)

3. Pump part number. (Paragraph G-2)

4. Part description.

5. Item part number.

6. Quantity required.

7. Shipping instructions.

8. Billing Instructions.

G-2 PART NUMBER:

The part number consists of a six (6) digit number, which

appears in the catalog. A one or two letter suffi x may follow

this number to designate the design confi guration. This

number is used for ordering and obtaining information.

G-3 MODEL NUMBER:

This designation consists of numbers and letters which

represent the discharge size, series, horsepower, motor

phase and voltage, speed and pump design. This number is

used for ordering and obtaining information.

G-4 SERIAL NUMBER:

The serial number block will consist of a six digit number,

which is specifi c to each pump and may be preceded by

a alpha character, which indicates the plant location. This

number will also be suffi xed with a four digit number, which

indicates the date the unit was built (Date Code). EXAMPLE:

A012345 0490.

Reference the six digit portion (Serial Number) of this number

when referring to the product.

FIGURE 8

POWER CORD (10)

CAP SCREW (6)

Lock washer (4)

COMPRESSION FLANGE (10a)

SNAP RING (8)

O-RING (12)

TERMINAL BLOCK (27)

TERMINAL

FIGURE 9

Summary of Contents for Barnes 3SE3024L

Page 12: ...12 FIGURE 10 ...

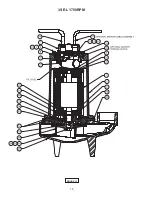

Page 14: ...14 FIGURE 11 3SE L 3450RPM ...

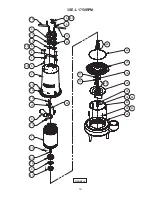

Page 18: ...18 3SE L 1750RPM FIGURE 13 ...

Page 24: ...24 Notes ...