14

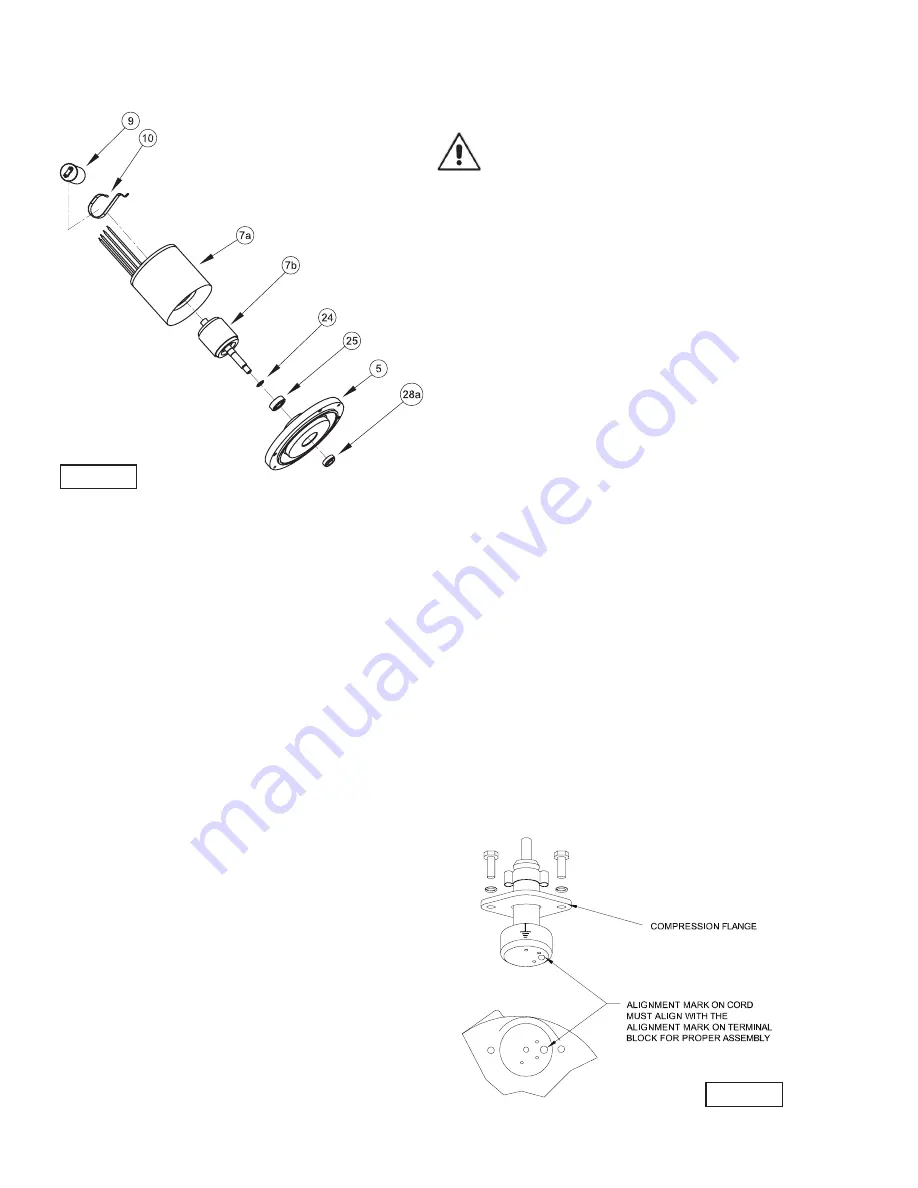

(25) and replace if required. If replacement is required, remove

bearing (25) from motor shaft using a wheel puller or arbor

press, see Figure 12

Check motor capacitor (9, single phase units) with an Ohm

meter by first grounding the capacitor by placing a screwdriver

across both terminals and then removing screwdriver. Connect

Ohm meter (set on high scale) to terminals. If needle moves

to infinity (∞) then drifts back, the capacitor is good. If needle

does not move or moves to infinity (∞) and does not drift back,

replace capacitor (9). To test the float switch (55 or 56 optional),

check for continuity between the pin receptacles of the cord

with the float in an “up” position. There should be no continuity

with the switch in the “down” position. Replace switch (55

or 56) if malfunctioning. If moisture sensors (4, optional) are

damaged, disconnect leads by removing machine screws (45)

and washers (46) from probes (4). Remove probes (4) from

seal plate (5). To test the temperature sensor (50, optional),

check for continuity between the black and white wires. If

found to be defective, contact a motor service station or Barnes

Pumps Service department. Inspect motor winding for shorts

and check resistance values. Check rotor for wear. If rotor or

the stator windings are defective, the complete motor must be

replaced.

IMPORTANT! - All parts must be clean before reassembly.

F-4.2) Reassembly:

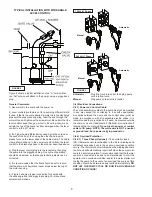

Moisture Sensors, DS Models -

If pump is equipped with

optional moisture sensors, reassemble by applying thread

compound to threads on probes (4) and install in upper seal

plate (5), see Figure 20 & 21. Connect wire assemblies (53) to

probes (4) with washers (46) and machine screws (45).

Thermal Sensors -

If pump is equipped with optional thermal

sensors, use terminal connectors (52) to connect wire

assemblies (51) to sensor leads. If sensor is not functioning,

contact factory approved Service Center or Contact factory

Service Department.

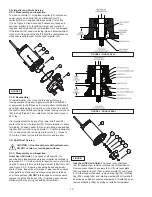

Bearings -

When replacing bearing, be careful not to damage

the rotor or shaft threads. Clean the shaft thoroughly. Press

bearing (25) on the motor shaft, position squarely onto the

shaft applying force to the inner race of the bearing only, until

bearing seats against the retaining ring (24) (Included with

motor).

Motor -

Slide lower bearing (25) and motor shaft

squarely into the seal plate (5) until bearing seats on

the bottom. Place stator over rotor, lining up motor bolts with

holes in seal plate (5). Position capacitor (9, single phase units)

so that it will lay on the opposite side of the cable entry bosses

of the motor housing (6). Reconnect capacitor leads. Torque

motor tie bolts to 17 in-lbs. Set square ring (27) in groove on

seal plate (5).

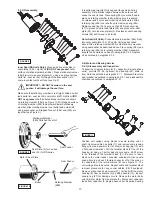

F-4.3) Wiring Connections:

Check power cables (16) and control cable (56, if used), for

cracks or damage and replace if required (see Figure 14).

Make internal wiring connections which are independent of

the terminal block as shown, using connectors (48) and wire

assemblies (49) and (63) as required. Do not use wire nuts. Slip

motor leads and groud wire through fiberglass sleeve. Lower

motor housing (6) down onto seal plate (5) while aligning holes

and stringing motor leads through the cable entry bore(s).

(Slipping cords inside a 1 ft. length of .5” conduit makes this

easier). Place socket head cap screws (47) through seal plate

(5) into motor housing (6) and torque to 60 in-lbs.

Reconnect motor and optional control leads to the underside

of the terminal block(s) (21), (54 optional) as shown in

Figure 13. Note that the pins are numbered underneath the

terminal block. Place o-ring (20) into groove in terminal block

and lubricate with dielectric oil. Press the terminal block (21)

into the housing so it seats completely below the snap ring

groove. Place snap ring (19) into groove in cable entry bore of

housing. Repeat terminal block installation for control cable, if

equipped.

F-4.4) Cable Assemblies:

Power/Control Cable- Refill the cooling oil as outlined in

paragraph F-1.3. Make wire connections as outlined in

paragraph F-4.3. Insert female end of cable plug into housing

bore aligning timing mark with hole in terminal block (21) see

Figure 15. Compress cable plug with compression flange

(16a) by tightening hex bolts (11) into the housing (6). Torque

to 132 in-lbs.

SECTION: G REPLACEMENT PARTS

G-1

FIGURE 12

FIGURE 15

Summary of Contents for 104872

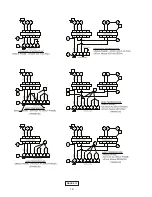

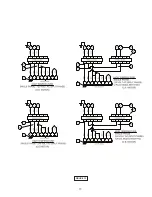

Page 16: ...16 FIGURE 13 ...

Page 17: ...17 FIGURE 13 ...

Page 18: ...18 FIGURE 13 CONTIUED ...

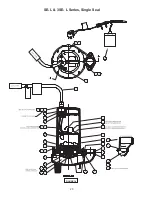

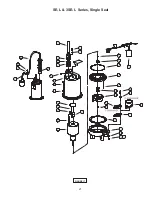

Page 20: ...20 FIGURE 16 SE L 3SE L Series Single Seal ...

Page 21: ...21 FIGURE 17 SE L 3SE L Series Single Seal ...

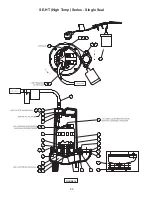

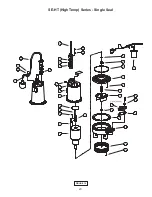

Page 22: ...22 FIGURE 18 SE HT High Temp Series Single Seal ...

Page 23: ...23 FIGURE 19 SE HT High Temp Series Single Seal ...

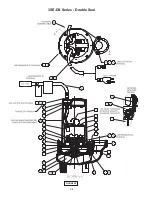

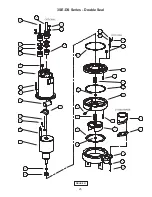

Page 24: ...24 FIGURE 20 3SE DS Series Double Seal ...

Page 25: ...25 FIGURE 21 3SE DS Series Double Seal ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...