12

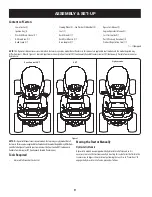

ASSEMBLY & SET-UP

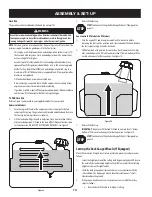

1.

Remove the seat adjustment knob (a) from the bottom of the seat (b). See

Figure 6.

(a)

(b)

(c)

Figure 6

2.

Align the seat (b) over the seat pivot bracket (c) as shown in Figure 6 and fit

the seat (b) onto the seat pivot bracket (c) inserting the two tabs on the seat

(b) bottom into the slots on the seat pivot bracket (c).

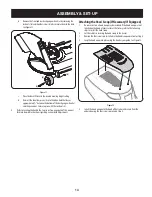

3.

Slide the seat (b) rearward in the seat pivot bracket (c), lining up the center

rear slot in the seat pivot bracket (c) with the remaining hole in the seat (b)

base. See Figure 7.

(b)

(c)

(a)

Figure 7

NOTE:

Be certain the two seat tabs engage the seat pivot bracket as shown in

the bottom right inset of Figure 7.

4.

Select the desired position for the seat (b), and secure with the adjustment

knob (a) removed in Step 1. See Figure 7.

5.

To adjust the position of the seat, remove the adjustment knob (a) on the

bottom of the seat (b). Slide the seat (b) forward or backward as desired.

Reinstall the adjustment knob (a). See Figure 7.

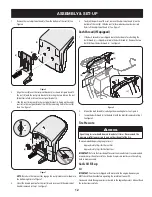

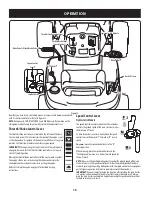

Dash Shroud (If Equipped)

1.

If the dash shroud (a) was shipped loose, the hardware for attaching the

dash shroud (a) is shipped installed in the dash shroud (a). Remove the two

bolts (b) from the dash shroud (a) . See Figure 8.

(b)

(a)

(c)

(a)

(b)

Figure 8

2.

Mount the dash shroud (a) and align the mounting holes. See Figure 8.

3.

Secure the dash shroud (a) to the dash (c) with the bolts (b) removed in Step 1.

See Figure 8.

Tire Pressure

WARNING

Equal tire pressure should be maintained at all times. Never exceed the

maximum inflation pressure shown on the sidewall of the tire.

The recommended operating tire pressure is:

•

Approximately 10 psi for the rear tires

•

Approximately 14 psi for the front tires

IMPORTANT:

Refer to the tire sidewall for exact tire manufacturer’s recommended

or maximum psi. Do not overinflate. Uneven tire pressure could cause the cutting

deck to mow unevenly.

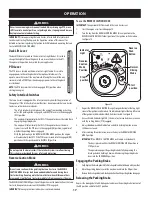

Gas & Oil Fill-up

Oil

IMPORTANT:

Your tractor is shipped with motor oil in the engine. However, you

MUST check the oil level before operating. Be careful not to overfill.

Service and check the engine oil as instructed in the Engine Operator’s Manual. Read

the instructions carefully.