OPERATING PRINCIPLES

• With release valve closed, an upward

stroke of the jack handle draws oil from the

reservoir tank into the plunger cavity.

Hydraulic pressure holds a valve closed,

which keeps the oil in the plunger cavity.

• A downward stroke of the jack handle

releases oil into the cylinder, which forces

the ram out. This raises the saddle. (NOTE:

To avoid damage to the cylinder if the load

exceeds the rated capacity of the jack, oil

is automatically released back into the

reservoir through the safety overload

valve.)

• W h e n t h e r a m r e a c h e s m a x i m u m

extension, oil is bypassed back into the

reservoir to prevent an over-extended ram

stroke and possible damage to the jack.

• Opening the release valve allows oil to flow

back into the reservoir. This releases

hydraulic pressure on the ram, which

results in lowering the saddle.

HOW TO USE YOUR JACK

RAISING THE JACK

• Chock the vehicle wheels with appropriate

devices to prevent vehicle from moving and

to ensure lifting stability.

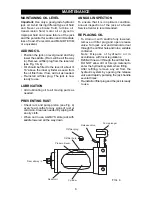

• Close the release valve by turning the jack

handle clockwise until tight. (see Fig. 3)

• Refer to the vehicle manufacturer’s owner’s

manual to locate approved lifting points on

the vehicle. Position jack so that the saddle

(see Fig. 3) is centered under the load at

an appropriate lift point.

• Pump jack handle until saddle ALMOST

contacts the vehicle. Check to see that the

saddle is centered and will contact the load

lifting point firmly.

OPERATION

• Continue to pump the jack handle to lift the

vehicle to the desired height. After lifting,

immediately support the load with

appropriately rated jack stands BEFORE

working on the vehicle.

Rated capacity of jack stands is

per

pair

, it is

NOT

the sum of individual

capacities unless specifically noted to the

contrary by the jack stand manufacturer.

Do Not

exceed rated capacity.

Ensure

that

the vehicle support points are fully captured

between the outer lugs of both jack stands.

Use

a matched pair of jack stands

per

vehicle to support

1

end

only

.

Use

1 pair

per vehicle

only

. Failure to do so may

result in sudden loss of load, which may

cause personal injury and/or property

damage.

LOWERING THE JACK

To avoid crushing injuries and property

damage: Keep hands and feet clear of work

area when lowering load.

• Raise load high enough to clear the jack

stands, then carefully remove jack stands

(

always

used in pairs).

• SLOWLY open the release valve by turning

the handle counterclockwise, but never

more than 1/2 full turn. If the load fails to

lower:

a. Use another jack to raise the vehicle

high enough to reinstall jack stands.

b. Remove the affected jack and then the

stands.

c. Using the other jack, lower the load by

turning the operating handle counter-

clockwise, but no more than 1/2 full turn.

• After removing jack from under the load,

push saddle down to reduce ram exposure

to rust and contamination.

5

!

!