8

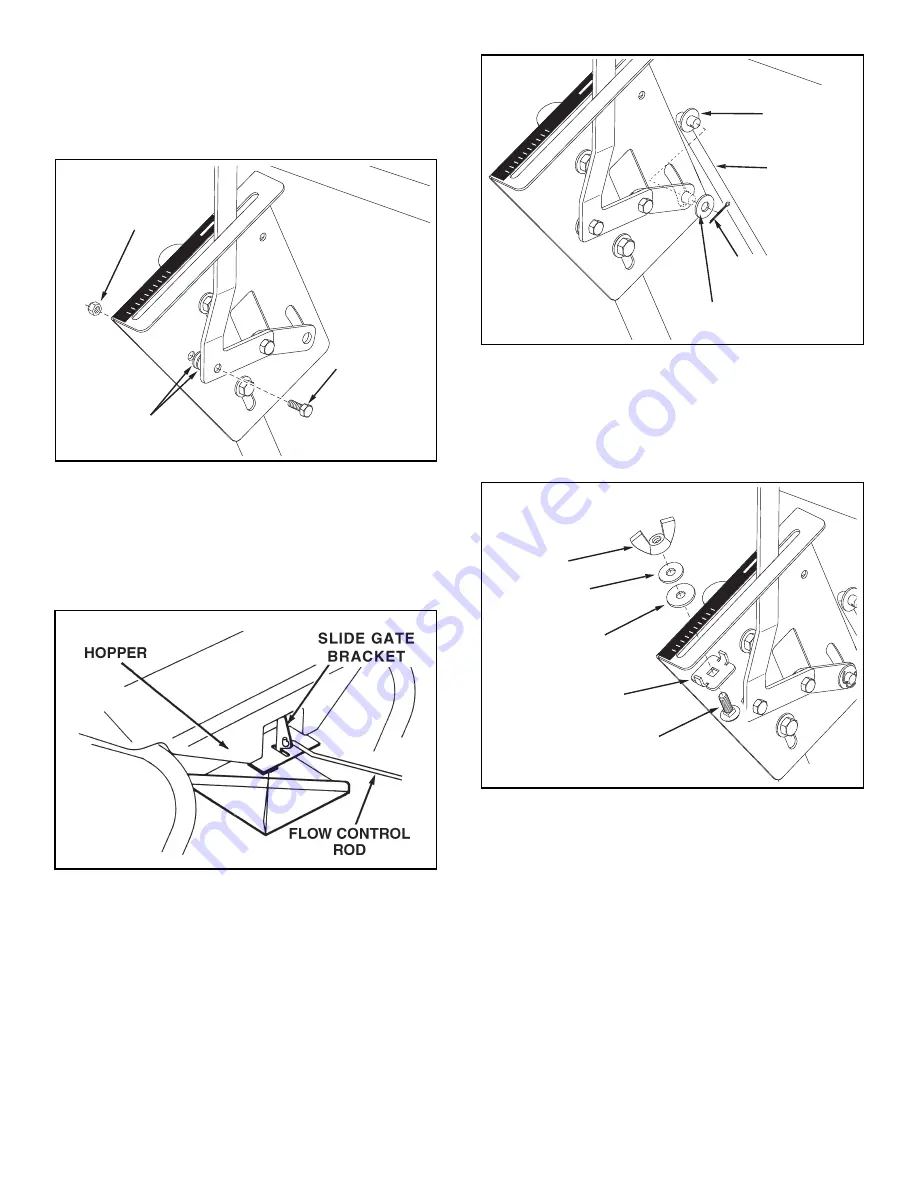

• Hook the double bent end of the flow control rod

through the hole in the slide gate bracket located near

the bottom of the hopper. See figure 10.

• Assemble the flow control arm to the flow control

mounting bracket using a 1/4" x 1" hex bolt, two nylon

washers and a 1/4" nylock hex nut.

Tighten carefully.

The flow control arm should be snug but should pivot

with no more than slight resistance. See figure 9.

FIGURE 9

• Place a 5/16" flat washer onto the other end of the

flow control rod. Insert the end of the rod through the

curved slot in the flow control mounting bracket and

through the hole in the flow control link. Secure with

a 5/16" flat washer and a 3/32" x 3/4" cotter pin. See

figure 11.

NOTE:

You can leave off the second washer if there is

not enough room on the end of the rod.

FIGURE 10

OFF

ON

1

2

3

4

6

7

8

9

10

5

1/4" x 1"

HEX BOLT

1/4" NYLOCK

HEX NUT

NYLON

WASHERS (2)

• Place the adjustable stop into the "ON" end of the slot

in the top of the flow control mounting bracket. Secure

with the 1/4" x 3/4" carriage bolt, a nylon washer, a

5/16" flat washer and the nylon wing nut. See figure

12.

FIGURE 12

FIGURE 11

NYLON

WING NUT

OFF

ON

1

2

3

4

6

7

8

9

10

5

5/16" FLAT

WASHER

NYLON

WASHER

ADJUSTABLE

STOP

1/4" x 3/4"

CARRIAGE BOLT

5/16" FLAT

WASHER

3/32" HAIR

COTTER PIN

FLOW

CONTROL

ROD

OFF

ON

1

2

3

4

6

7

8

9

10

5

5/16" FLAT

WASHER

• Position the flow control mounting bracket. See figure

13.

a. Push on flow control arm until it locks in "OFF"

position.

b. Slide flow control mounting bracket along tube

until closure plate in bottom of hopper just

closes.

c. Snug the 5/16" nylock hex nuts just enough to

hold flow control mounting bracket in place.

d. Set adjustable stop at "5". Pull flow control arm

against stop. Verify that closure plate has opened

about half way.

e. If closure plate does not open half way, adjust

position of flow control mounting bracket until

closure plate will open about half way at "5"

and will still close when arm is locked in "OFF"

position.

Tighten

the 5/16" nylock hex nuts.