13

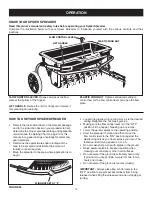

OPERATING TIPS

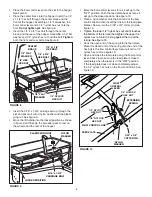

• To help prevent

granular

material from compacting

and clogging the hopper, avoid unnecessary towing

when the hopper flow plates are closed.

• Reduce the flow setting for speeds slower than

3 M.P.H. and increase the setting for higher speeds.

• To avoid misses or striping, overlap the previous

wheel tracks by approximately 5" to 6".

FIGURE 25

MAINTENANCE

Spike points are sharp. Exercise caution

when handling or working near spike disks.

Service Dates

Check for loose fasteners

X

Lubrication

X

Cleaning

X

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service.

Bef

ore each use

After each use

Ev

ery y

ear

Bef

ore stor

age

CUSTOMER RESPONSIBILITIES

• Read and follow the maintenance schedule and the maintenance procedures listed in this section.

CHECK FOR LOOSE FASTENERS

•

Before each use make a thorough visual check of

the spiker spreader for any bolts and nuts which may

have loosened. Retighten any loose bolts and nuts.

LUBRICATION

•

Apply a few drops of oil to wheels and to plastic

bearings in spike disks and at end of spike axle.

• Remove chain cover, clean and oil drive chain.

CLEANING

• Always empty spiker spreader after each use, storing

leftover material in it's original bag.

•

Wash the spiker spreader and dry thoroughly after

each use.

•

For easiest application, first apply material across

both ends of the area. Two or three passes on each

end are sufficient. Then apply material back and forth

as shown. Use the end areas for turning around,

shutting off the spreader as you enter the end areas

and turning the spreader on again as your leave the

end areas for your next pass. See figure 25.

• If lawn is odd shaped, spread a border around the

edges and then spread between the border.

•

Be careful when spreading around ornamental plants

because weed control chemicals can damage these

plants.

• Empty the spiker spreader, storing leftover material in

it's original bag.

• Apply a light coat of oil on exposed metal to help

prevent rust.

STORAGE

•

Wash the spiker spreader and dry thoroughly before

storing.

• Store in a clean, dry area.

Flow Rate Setting

MATERIAL

TYPE

At 3 M.P.H.

SETTING CHART

Fertilizer

Granular / Pelleted

5-6 / 6-7

Grass Seed

Fine / Coarse

5-6 / 7-8

3 M.P.H. is equivalent to traveling 100 feet in 23 seconds.