13 ― English

OPERATION FOR DRILL/DRIVER

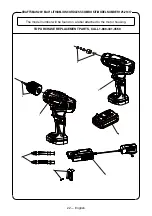

WARNING:

Make sure to insert the bit

straight into the chuck jaws. Do not insert the

bit into the chuck jaws at an angle and then

tighten, as shown in figure 10. This could

cause the bit to be thrown from the tool,

resulting in possible serious personal injury

or damage to the chuck.

REMOVING BITS

See Figure 9, page ii

1. Lock the trigger switch by placing the

direction-of-rotation selector in the OFF

(center-lock) position.

2. Open the chuck jaws by rotating the

chuck in the direction of the arrow marked

RELEASE.

NOTICE:

Do not use a wrench to tighten or

loosen the chuck jaws.

3. Remove the bit.

DRILLING HOLES OR DRIVING SCREWS

See Figure 11, page iii

1. Rotate the mode selector to the drill

position or one of the 19 driver torque

positions.

2. Check that the direction-of-rotation

selector is at the correct setting (forward

or reverse).

3. Use LO (1) speed for torque applications

and HI (2) speed for fast drilling or driving

applications. Refer to Two-Speed Gear

Box and Adjustable Torque Clutch.

4. When possible, secure the material in a

vise or with clamps to keep it from turning

when drilling or driving.

5. Hold the tool firmly, and place the bit at the

point to be drilled, or where the screw is to

be driven.

6. Depress the trigger switch to start the tool.

7. Move the bit into the workpiece, applying

only enough pressure to keep the bit

cutting. Do not force the tool or apply side

pressure to elongate a hole. Let the tool

do the work.

8. When drilling or driving into hard, smooth

surfaces, use a center punch to mark

the desired location of the hole. This will

prevent the bit from slipping off-center as

the hole is started.

9. If the bit jams when drilling into the

workpiece or if the tool stalls, stop the

tool immediately. Remove the bit from the

workpiece and determine the reason for

jamming.

NOTICE:

This tool is equipped with an

electric brake. When the brake is functioning

properly, sparks may be visible through the

vent slots in the housing. This is normal and

results from the action of the brake.

WOOD DRILLING

For maximum performance, use high-speed

steel or brad-point bits for wood drilling.

1. Select drill mode ( ).

2. Begin drilling at a very low speed to

prevent the bit from slipping off the starting

point.

3. Increase speed as the drill bit bites into the

material.

4. When drilling a “through” hole, place a

block of wood behind the workpiece to

prevent ragged or splintered edges on the

back side of the hole.

METAL DRILLING

For maximum performance, use high speed

steel bits for metal or steel drilling.

1. When drilling metals, use light oil on the

drill bit to keep it from overheating. The oil

will prolong the life of the bit and increase

the drilling action.

2. Select drill mode ( ).

3. Begin drilling at a very low speed to

prevent the bit from slipping off the starting

point.

4. Maintain a speed and a pressure which

allow cutting without overheating the bit.

Applying too much pressure will:

• Overheat the drill

• Wear the bearings

• Bend or burn bits

• Produce off-center or irregularly shaped

holes

5. When drilling large holes in metal, start

with a small bit, then finish with a larger

bit.