- 11 -

WARNING

Do not make any adjustments, or load, unload

work from vise when machine is running!

Adjusting Poor Cutting

The machine has been adjusted and

power-tested with several test cuts before

leaving the factory to insure proper cutting. If

th

e machine gives poor cuts

, correct it as

follows.

1. Bad cuts due to blade worn, replace a new

blade.

2. The saw uses fixed ball bearings and can

be adjusted ball bearing by eccentric

bearing shaft (B) in Fig.15, 16 (A) is to

keep the tolerance with the blade. For

keeping proper cutting, the best way is to

replace them every three or six months

depending on the frequency of service.

3. Poor cuts can be made because the nuts

(A) in Fig.15, 16 are getting loose. Then

tighten it properly.

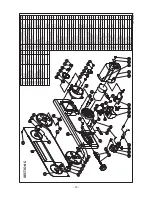

Fig. 15

Fig. 16

WARNING

SHUT OFF THE POWER SOURCE BEFORE

MAKING

ADJUSTMENT, MAINTENANCE, O

R

INSTALLING OR UNINSTALLING PARTS.

Changing the Motor Carbon

Brushes

If the motor is making an unusual noise then the

carbon brushes may need to be replaced.

1. Disconnect machine from power supply.

2. Remove two tap screws connected with

on/off switch box, and three Phillips head

screws around cover base. (Fig. 17)

3. There are two plastic covers on the motor

(Fig.18) after uncovering the motor’s cover.

Remove plastic covers.

4. There are coppers sheet with wiring

covered on the carbon brushes (Fig.19).

5. Slide copper sheet to the one way (Fig.20),

the carbon brush will jumps out (Fig.21).

6. Replace the carbon brushes

(Fig. 22)

.

Both brushes must be replaced at the

same time.

7. Replace the carbon brushes’ cover and

motor cover.

Fig. 17

A

B

A

B

Summary of Contents for CX112

Page 1: ...CX112 PORTABLE METAL BAND SAW User Manual Version 1 0 ...

Page 5: ... 3 Electrical Schematic ...

Page 15: ...1030318 V2 SECTION A 13 ...

Page 16: ...1030318 V2 SECTION B 14 ...

Page 17: ...1030318 V2 SECTION C 15 ...