17

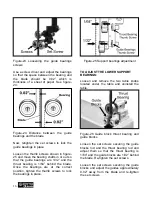

BLADE TENSION

A properly tensioned blade is very

important to get the best performance from

any band saw. If the blade is too loose

there is a possibility that the blade will slip

or drift off the line while in operation and it

will be hard to have accuracy in the line of

cut. If the blade is tensioned too tightly, it

will be very difficult to make tighter radius

cuts and there will be a great possibility of

blade breakage. When using a wider blade

for making straight cuts, for re-sawing or

making wide radius cuts, tighter blade

tension is recommended; while using

narrower blades for cutting shorter stock or

making tighter radius cuts, less blade

tension is recommended.

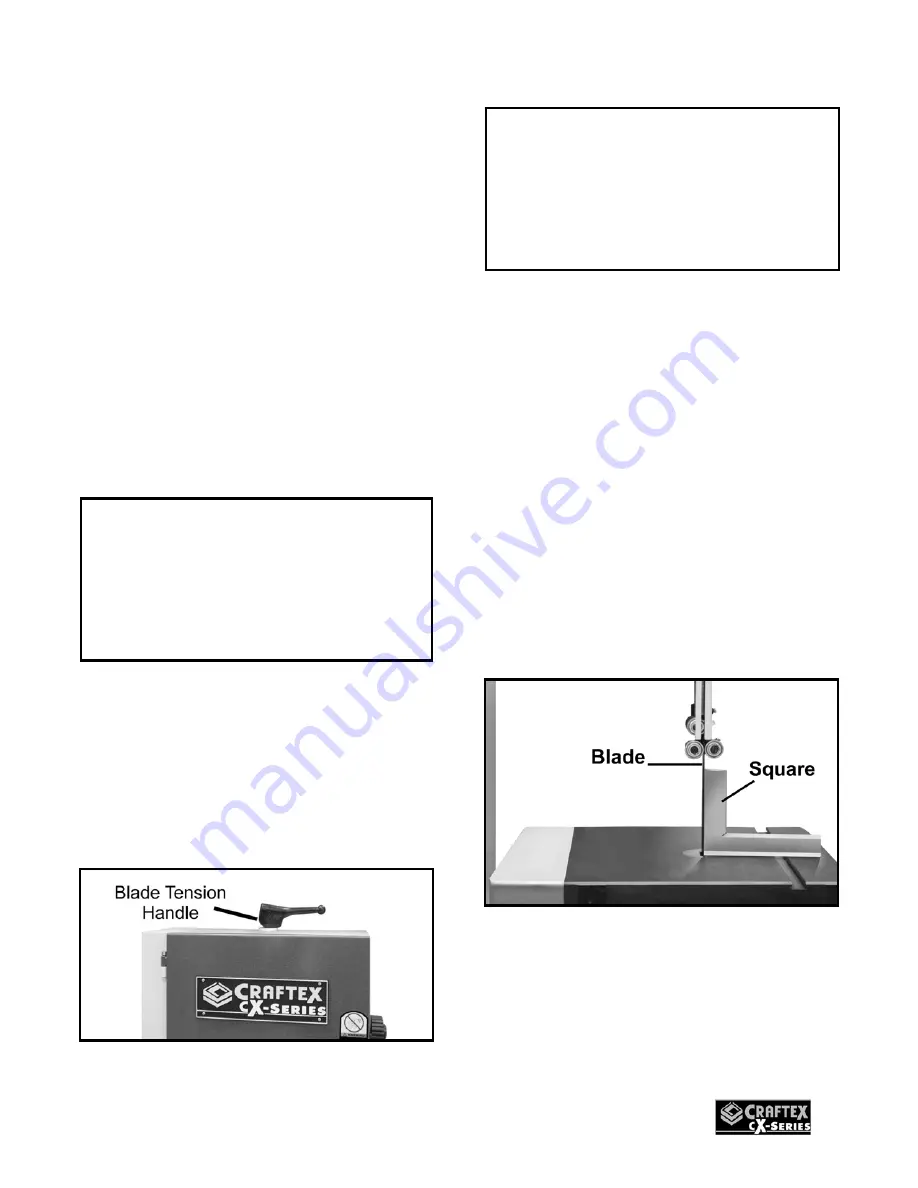

BLADE TENSION ADJUSTMENT

To adjust the blade tension, turn the blade

tension handle shown in figure-27

clockwise to increase the blade tension and

counter-clockwise to decrease it.

To release tension simple lift the handle up.

Figure-27 Blade tension adjustment

TABLE ADJUSTMENT

CX104 features a table stop which allows

the table to easily come to 90° if the table is

tilted.

To adjust the table stop so that the table

sits at 90°, you should first make sure the

switch is in “OFF” position and the power

cord is unplugged.

Loosen the two table lock knobs under the

table.

Place a square on the table as shown in

figure-28.

Figure-28 Table adjustment

Loosen the lock nut on the table stop bolt

and thread the table stop bolt in or out so

that the square is touching the table and the

blade with its full length and the table is at a

90° with the blade.

IMPORTANT

The information above is just a guideline

for you to understand to set the blade

tension according to the cut. However,

understanding the blade tension

adjustment comes with practice.

IMPORTANT

To prolong the life of the blade and

reduce blade stretching, when the

machine is not in use for period of 24

hours or more release the tension on the

blade.