Standard Recommended Procedure 206-455-AEN | Issue 1 | November 2018 | Page 12 of 14

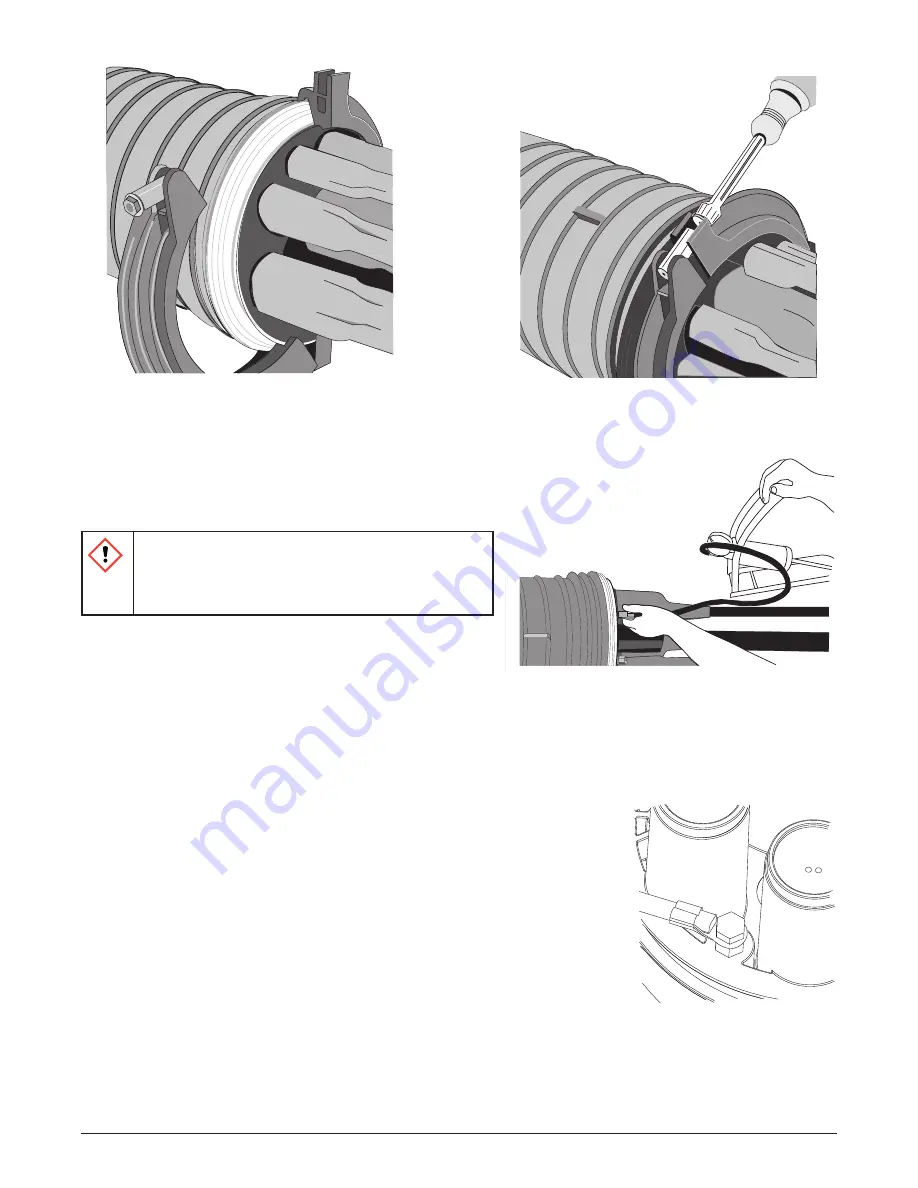

13. Perform Flash Test

Step 1:

Inject 12 to 14 psi (maximum) of air into the closure

. Check pressure after

each 25 pumps.

WARNING:

To avoid a potentially hazardous

situation that could result in death or serious

injury, do not exceed 14 psi (100 kpa) gauge

pressure. The closure could burst.

Step 2:

Apply soapy water to the edges of the heat-shrink

tubing and watch closure for signs of leakage

(bubbling of soap).

NOTE:

A correctly sealed closure maintains pressure with no leaks.

Step 3:

After the flash test has been performed and the closure sealed correctly, carefully remove the air valve

and allow air to escape.

14. Ground the Closure (Optional)

Step 1:

Apply a thin coat of lubricant retained previously to the threads of a

solid, two-piece, nonvented grounding plug

Step 2:

Install the larger plug into the end cap from the outside of the end cap

finger- tight, then another half turn (approximately 40 to 60 in-lb)

Step 3:

Connect a grounding cable (not supplied) to the plug.

Step 4:

Screw the smaller insert into the plug.

Step 5:

Tighten the insert using a small adjustable wrench.

Step 6:

Terminate the other end of the ground per local practices.

KPA-1723

KPA-1724

Figure 26

KPA-1726

Figure 27

TPA-5999

Figure 28