STANDARD RECOMMENDED PROCEDURE 009-221 | ISSUE 8 | AUgUST 2015 | PAgE 10 OF 10

Corning Optical Communications LLC • PO Box 489 • Hickory, NC 28603-0489 USA

800-743-2675 • FAX: 828-325-5060 • International: +1-828-901-5000 • www.corning.com/opcomm

Corning Optical Communications reserves the right to improve, enhance, and modify the features and specifications of Corning Optical Communications products

without prior notification. A complete listing of the trademarks of Corning Optical Communications is available at www.corning.com/opcomm/trademarks. All other

trademarks are the properties of their respective owners. Corning Optical Communications is ISO 9001 certified. © 1997-2000, 2003, 2009, 2015 Corning Optical

Communications. All rights reserved.

9. Maintenance

The unit requires very little maintenance to ensure fibers and parts remain in good condition.

• External components may be cleaned occasionally with a damp, nonabrasive cloth.

• Check nuts, bolts, and screws; tighten as needed.

•

Check fiber optic cable to make sure bends do not exceed the minimum bend radius.

• Check cables for unnecessary strain, for crimping or crushing at entries and exits, and for

damage.

• Check unit record labels to make sure all are clear and accurate.

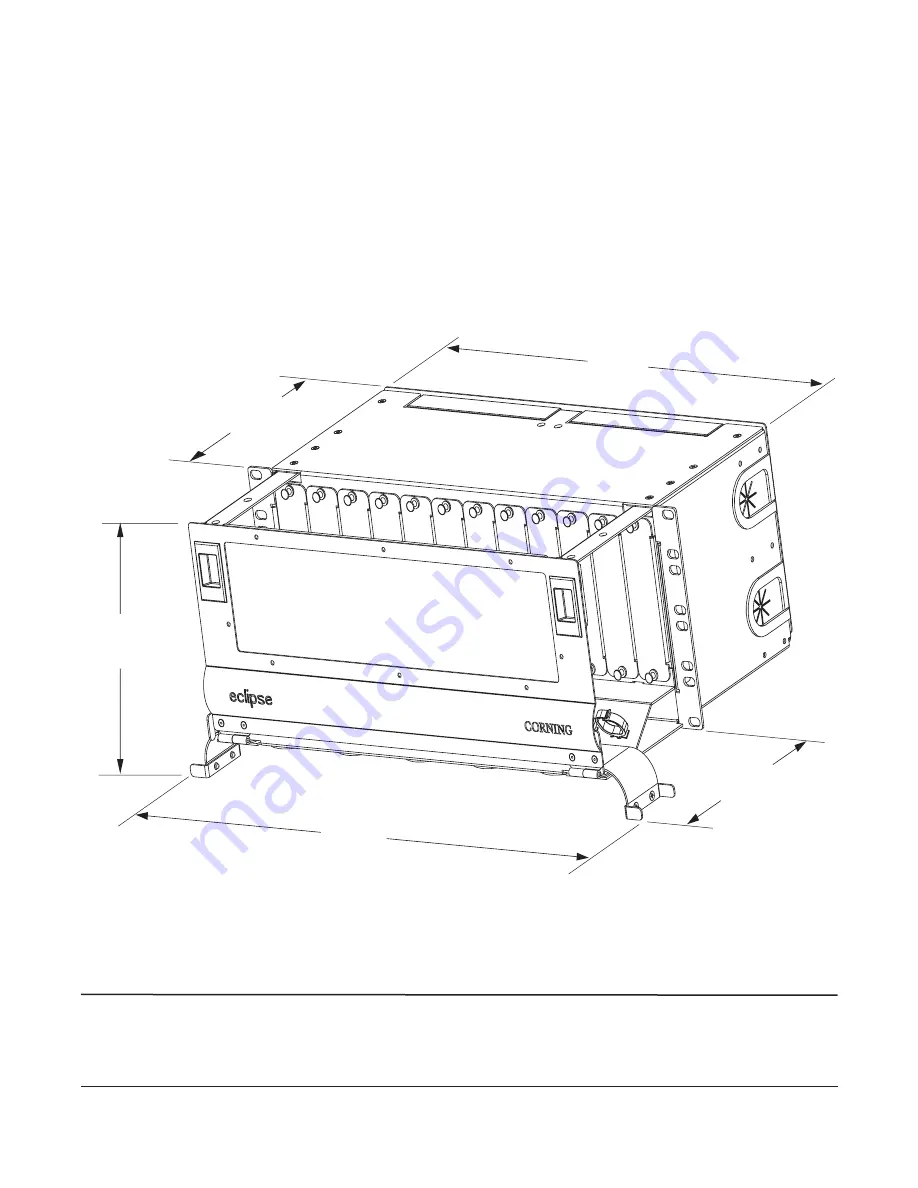

10. Dimensions

Figure 17

44 cm

(17 in)

17.8 cm

(7 in)

21.3 cm

(8 in)

51.6 cm

(20 in)

12.4 cm

(5 in)

KPA-2205