16

C6.2.15/0815/E

3.8 Oil separator

During any operating cycle of Copeland Scroll Digital compressors, there is a loaded state during

which the compressor operates at full capacity. The velocity of gas during this loaded state is

sufficient to return oil back to the compressor. Laboratory tests have established that there is no

problem in oil return, even when the length of interconnecting pipe used is

100 metres and the vertical elevation is 30 metres. Based on such performance, Emerson

Climate Technologies does not strictly recommend the use of an oil separator.

3.9 Accumulators

CAUTION

Inadequate lubrication! Bearing destruction!

Minimise liquid refrigerant

returning to the compressor. Too much refrigerant dilutes the oil. Liquid

refrigerant can wash the oil off the bearings leading to overheating and

bearing failure.

Due to Copeland Scroll’s inherent ability to handle liquid refrigerant in flooded start and defrost

cycle operation, an accumulator is not required for durability in most systems. However, large

volumes of liquid refrigerant which repeatedly flood back to the compressor during normal off

cycles or excessive liquid refrigerant floodback during defrost or varying loads, no matter what

the system charge is, can dilute the oil. As a result, bearings are inadequately lubricated and

wear may occur.

To determine if the accumulator can be removed, dedicated tests must be carried out to ensure

that excessive liquid does not flood back to the compressor during defrost or varying loads. The

defrost test must be done at an outdoor ambient temperature of around 0°C in a high humidity

environment. Liquid floodback must be monitored during reversing valve operation, especially

when coming out of defrost.

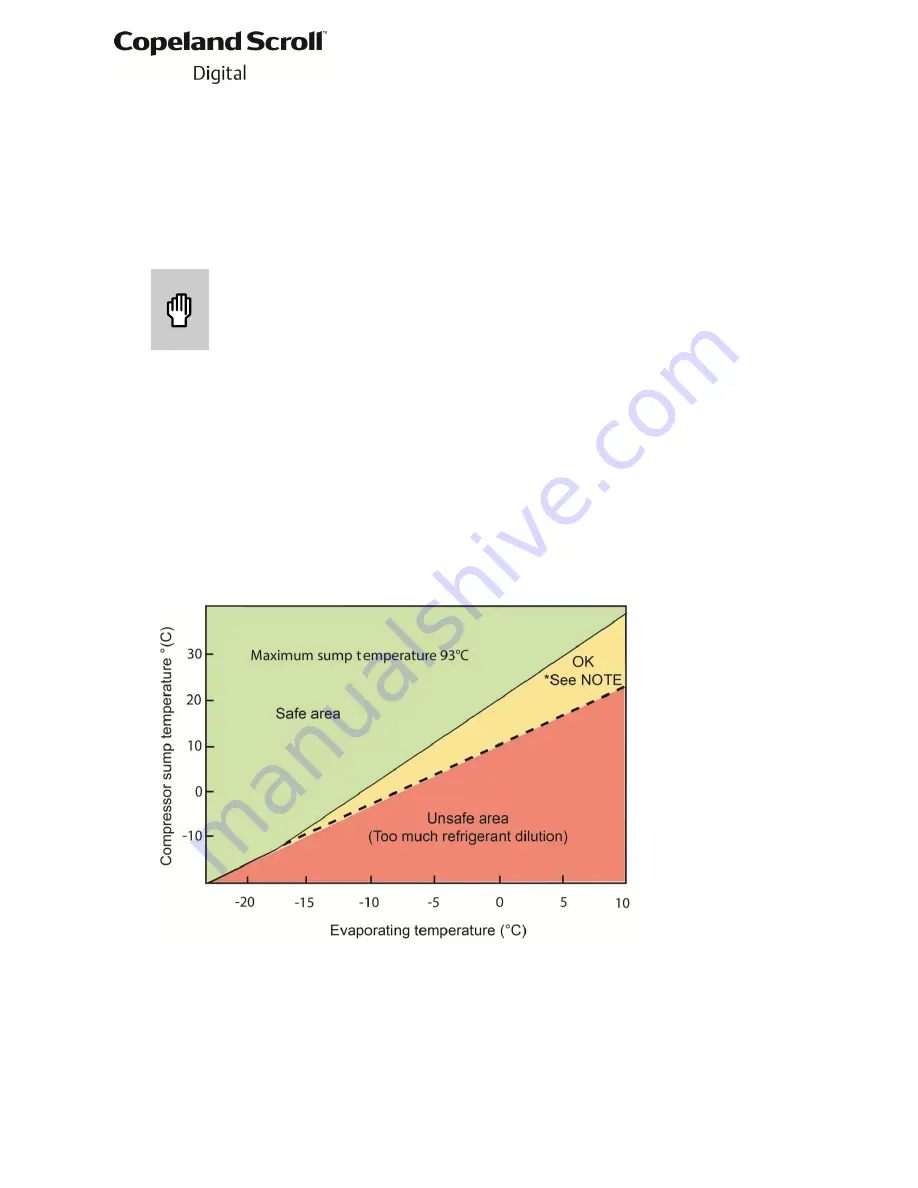

Excessive floodback occurs when the sump temperature drops below the safe operation line

shown in

Figure 27

for more than 10 seconds.

Figure 25: Bottom shell temperature

NOTE:

Operation in this refrigerant dilution area is safe in air-to-air heat pump heating

mode. For other applications, such as AC only, review expansion device to raise

superheat. A cold sump may result in high refrigerant migration after shutdown.

If an accumulator has to be used, the oil-return orifice

should be from 1 to 1.4 mm in diameter for

models ZRD42K* to ZRD81K* and ZPD34K* to ZPD91K*, depending on compressor size and

compressor floodback results. Models ZRD94K*, ZRD125K* and ZPD103K* to ZPD182K*

should use an orifice diameter of 2.0 mm.

A large-area protective screen with mesh no finer than

30 x 30 (0.6 mm openings) is required to protect this small orifice from plugging with system