14

C6.2.15/0815/E

Figure 23: Suction tube brazing areas

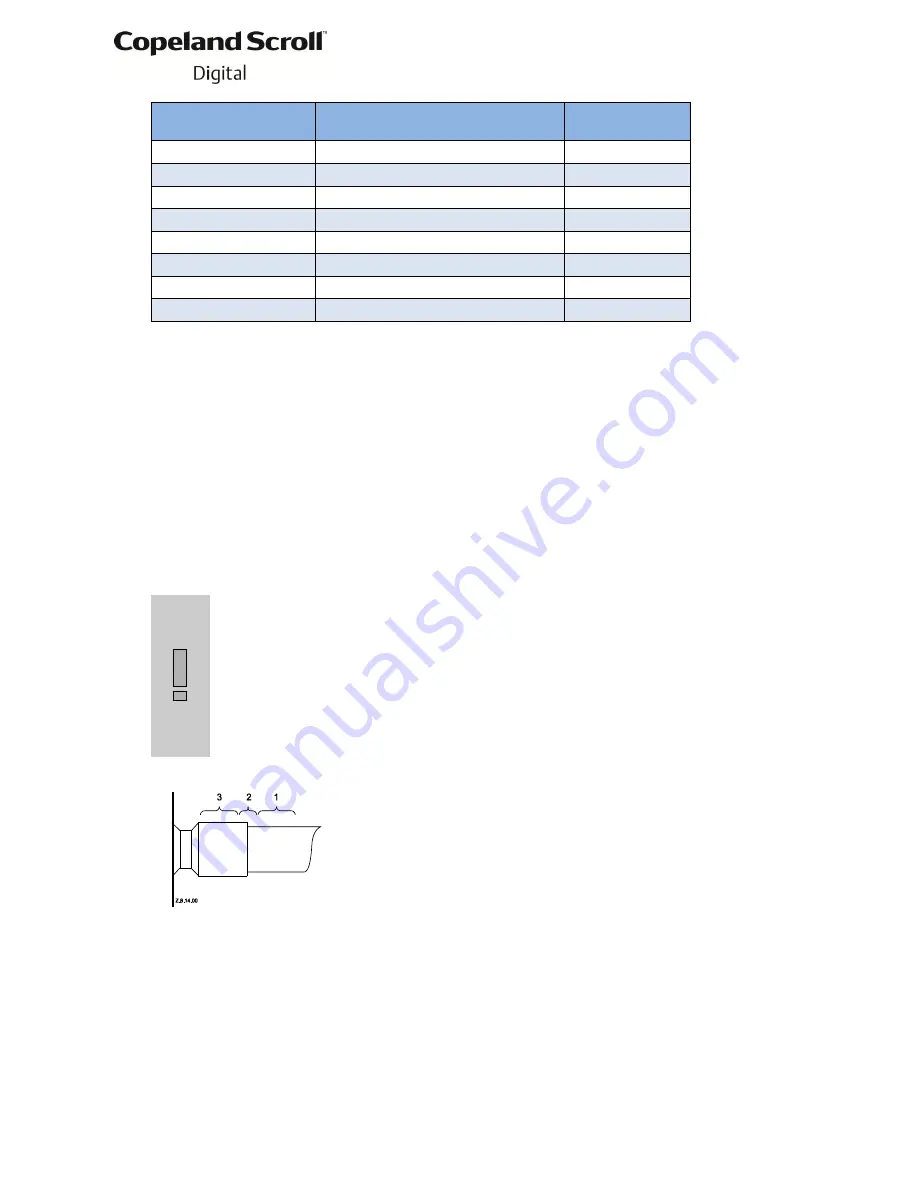

Compressor model

Base compressors

Available

voltages

ZPDT21MCE

ZP ZPD103KCE

TFD

ZPDT22MCE

ZP ZPD104KCE

TFD

ZPDT24MCE

ZP ZPD120KCE

TFD

ZPDT25MCE

ZP ZPD122KCE

TFD

ZPDT27MCE

ZP ZPD137KCE

TFD

ZPDT31MCE

ZP ZPD154KCE

TFD

ZPDT36MCE

ZP ZPD182KCE

TFD

ZRDT25MCE

ZR ZRD125KCE

TFD

Table 2: Tandem configurations with standard models and Digital Scroll compressors

3.5 Discharge check valve

There is

no

discharge check valve at the discharge port of Copeland Scroll Digital compressors

ZRD42K* to ZRD81K* and ZPD34K* to ZPD91K* since the high-side pressure is needed to

support the operation of the un-loader mechanism.

To avoid bypassing during the unloading process back to suction, a dynamic discharge valve is

fitted internally on the discharge port of the fixed scroll. This discharge valve cannot be used with

recycling pump-down because it is not leak-proof during the off period.

Models ZRD94K*, ZRD125K* and ZPD103K* to ZPD182K* work with an internal un-loader

mechanism (see

Figures 5 & 11

) and are equipped with a check valve in the discharge fitting

that will prevent backward flow of gas through the scroll when the compressor shuts off.

3.6 Brazing procedure

IMPORTANT

Blockage! Compressor breakdown!

Maintain a flow of oxygen-free

nitrogen through the system at very low pressure during brazing. Nitrogen

displaces the air and prevents the formation of copper oxides in the system.

If allowed to form, the copper oxide material can later be swept through the

system and block screens such as those protecting capillary tubes, thermal

expansion valves, and accumulator oil return holes.

Contamination or moisture!

Bearing failure!

Do not remove the plugs until

the compressor is set into the unit. This minimises any entry of contaminants

and moisture.

Copeland Scroll Digital compressors have copper-

plated steel suction and discharge tubes. These

tubes are far more robust and less prone to leaks

than copper tubes. Due to the different thermal

properties of steel and copper, brazing procedures

may have to be changed from those commonly used.

Refer to

Figure 25

and the procedure below for the

brazing of the suction and discharge lines to a scroll

compressor.

The copper-coated steel tubes on scroll compressors can be brazed in approximately the

same manner as any copper tube.

Recommended brazing materials: any Silfos material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is acceptable.

Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

Using a double-tipped torch, apply heat in area 1.

As the tube approaches brazing temperature, move the torch flame to area 2.