S260-20-9

7

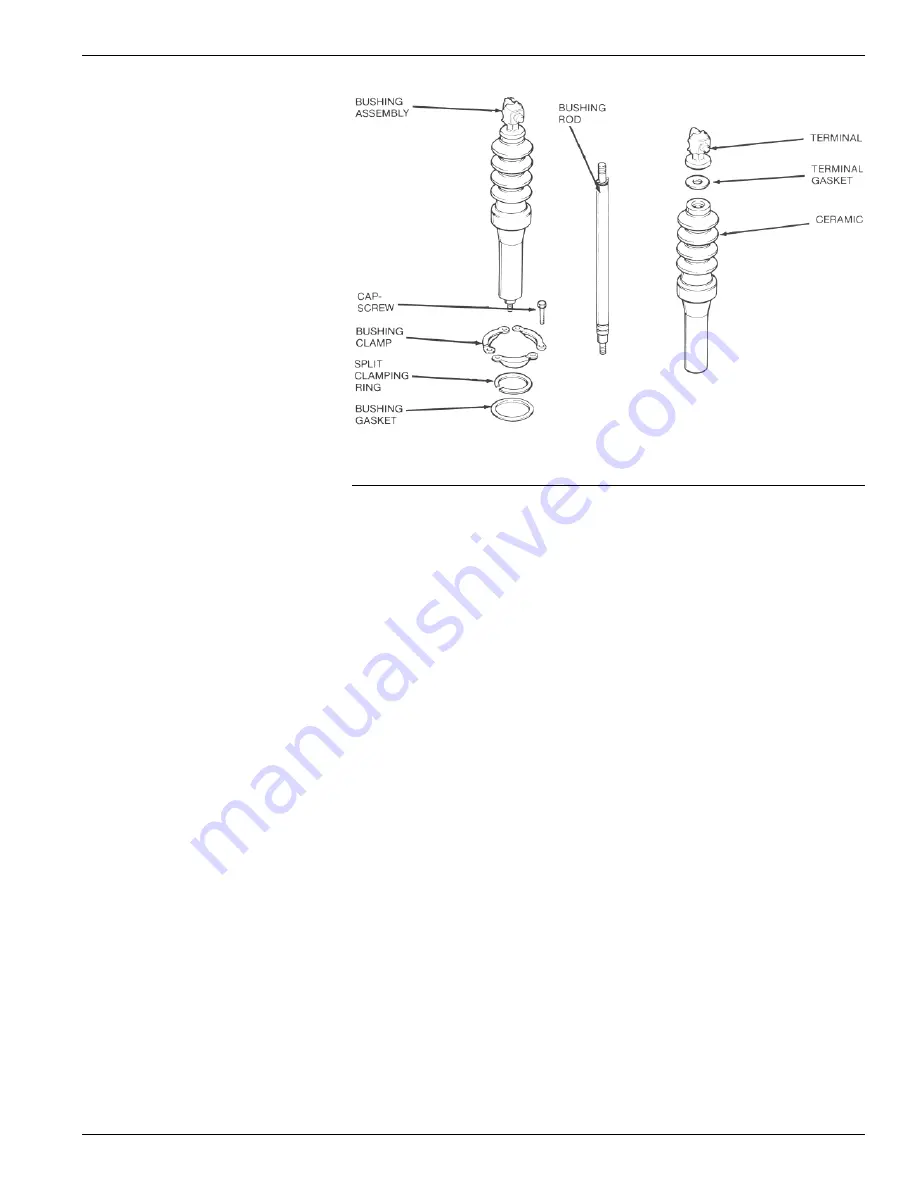

Figure 14.

Bushing parts.

TEST 2: Proceed as follows:

1. Close the switch.

2. Ground switch tank and head.

3. Ground the outer two bushings

(Phase A and Phase C).

4. Apply test voltage (37.5 kv) to the

center bushing (Phase B).

• The switch should withstand the

test voltage for 60 seconds.

TEST 3: Proceed as follows:

1. Open the switch.

2. Ground switch tank and head.

3. Connect and ground all three bush-

ings on one side of the switch.

4. Connect together the three bush-

ings on the other side of the switch.

5. Apply test voltage (37.5 kv) to the

ungrounded side of the switch.

• The switch should withstand the

test voltage for 60 seconds.

6. Reverse the test and ground con-

nections to the bushings.

7. Again apply test voltage (37.5 kv) to

the ungrounded bushings.

• The switch should withstand the

test voltage for 60 seconds.

TEST RESULTS: These high potential

withstand tests provide information on

the dielectric condition of the switch.

A. If the switch passes the closed con-

tacts tests (Test 1 and 2) but fails

the open contacts test (Test 3) the

cause is likely to be in one or more

of the main contact assemblies.

B. If the switch fails the closed con-

tacts tests (Test 1 and 2) the cause

is likely to be a diminished electri-

cal clearance or failed insulation.

C. After correcting the problem, retest

to confirm the repair.

SHOP REPAIR PROCEDURES

The procedures described in this sec-

tion should be performed under the

cleanest possible conditions. No spe-

cial tools are required for any of the

repair procedures.

Bushings

Bushing replacement generally con-

sists of a thorough cleaning and care-

ful examination for chips, cracks, or

other mechanical damage during the

periodic maintenance inspection.

Bushings must be replaced whenever

damage is discovered.

Note that the contact structures are

suppor ted from the bottom of the

bushings. If more than one bushing is

damaged, replace only one bushing at

a time to maintain contact alignment.

To replace a bushing refer to Figure

14 and proceed as follows:

1. With the switch untanked, remove

the nut, lockwasher and flatwash-

er holding the contact structure to

the lower end of the bushing rod.

2. Remove the three hex head cap-

screws and clamps that secure the

bushing to the head and lift out the

complete bushing assembly.

3. Remove and discard the lower bush-

ing gasket.

4. The complete bushing assembly can

be replaced or new porcelain only

can be installed depending upon the

extent of damage. If new porcelain

only is to be installed, proceed as

follows:

A. Unscrew the bushing terminal

and withdraw the rod from the

bottom of the porcelain; discard

the terminal gasket.

B. Insert the rod assembly all the

way into the new porcelain, mak-

ing sure the roll pin is seated in

the locking groove in the top of

the bushing.

C. Assemble the ter minal to the

bushing rod using a new terminal

gasket; tighten to a torque of 35

ft-lbs.

NOTE: Apply a very small amount of

petroleum jelly to the knurled surface

of the inside face of the terminal

before assembling the terminal to the

bushing rod.

5. Twist off the split aluminum clamping

ring from the old bushing and reuse

if it is in good condition; replace the

ring if damaged.

NOTE: The clamping ring cushions and

distributes the pressure between the

porcelain and the clamps. DO NOT OMIT.

6. Install the bushing assembly (new or

reworked) into the head casting

using a new lower bushing gasket.

Position the bushing with the stud-

end of the terminal pointing out-

ward.

7. Position the clamping ring with the

split centered between two clamp-

ing bolts.

8. Reassemble the bushing to the head

casting. Tighten the clamping bolts

evenly, a little at a time, to a torque

of 6-10 ft-lbs.

NOTE: Clamping forces must be applied

gradually and equally in rotation to each

bolt. This results in an evenly distributed

gasket sealing pressure.

9. Reconnect the bushing to the con-

tact structure.

10. Recheck contact alignment as spec-

ified on page 9 or 12.

Contacts

The Type VR switch utilizes two sets of

wedge-shaped moving contacts; one set

for arcing, the second set for load-carry-

ing (Figure 3). The Type VCR switch uti-

lizes a set of wedge-shaped contacts for

arcing, a set of bayonet-type contacts

for load carrying, and resistors in series

with the arcing contacts for damping

capacitor switching transients (Figure

2). Contact service and alignment pro-

cedures are similar for both switches.