User Manual 6414 Plus

MAN10xxx-01 14

3 Printer Setting and Control

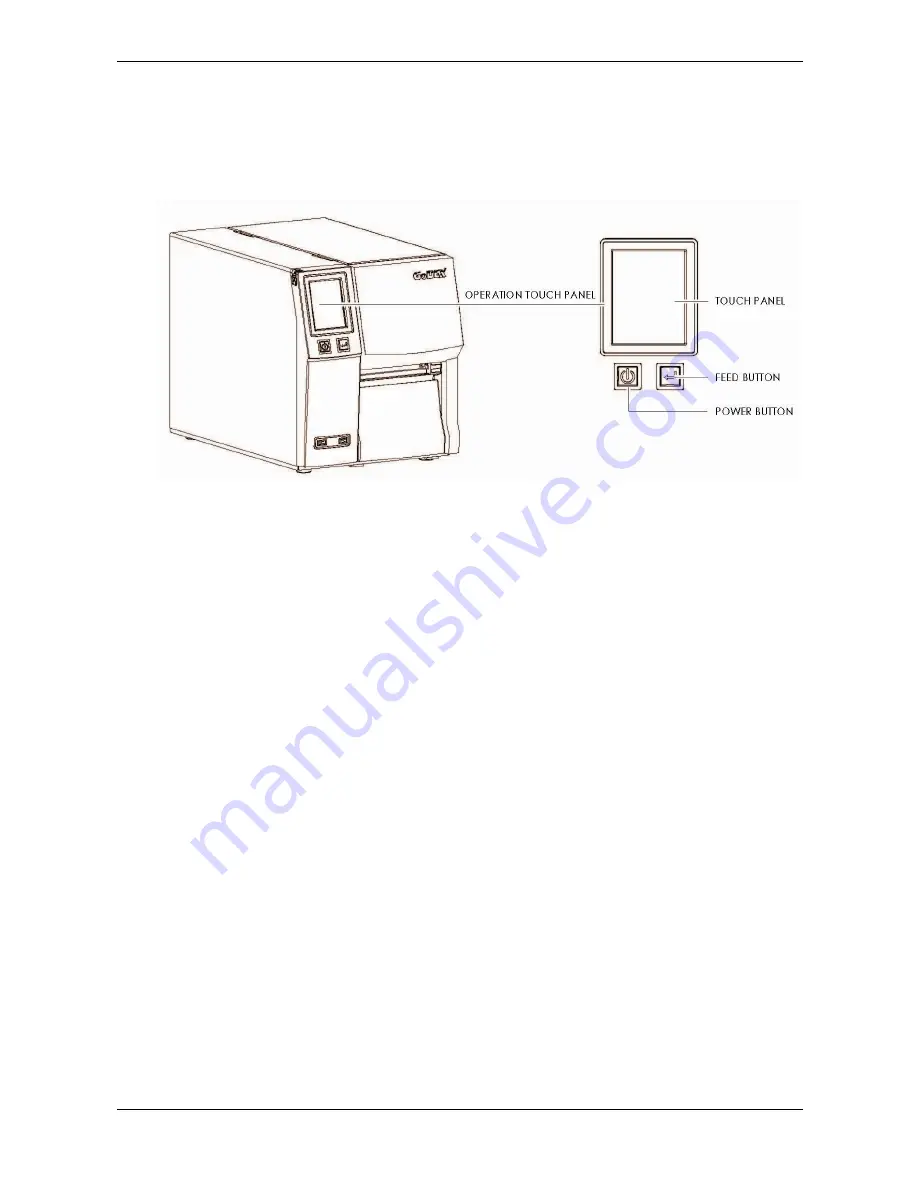

3.1 Operation Panel

Operation Panel Introduction

POWER Button

Press the POWER button to turn on the printer, and the START UP SCREEN appears. The printer is on

“ready to print” status, the LCD screen should display the message “READY“ on the screen.

When printer is turned on, keep pressing the POWER button for 3 second will turn the printer off.

FEED Button

When you press the FEED button, the printer moves the label to the defined stop position.

If you are using continuous labels, pressing the FEED button will move label stock until you release the

button again.

If you are using individual labels, pressing the FEED button will move only one label.

If the label does not stop at the correct position, you need to run the auto-detection function on the label

stock, please see Section 3.4 Label Calibration and Self Test.

PAUSE PRINTING_FEED Button

Pressing the FEED button while the printer is in standby mode will set the printer to pause mode. In this

mode, the printer can receive commands, but it can only process them when it is reset to standby mode.

Pressing the FEED button again will reset the printer to standby mode.

Pressing the FEED button during printing will interrupt printing. When the PFEED button is pressed again,

the printer resumes printing. Example: While a 10-label print job is running, you press the FEED button to

pause the printer. Two of the labels have been printed. To resume printing and print the remaining eight

labels, you press the FEED button again.

CANCEL PRINTING_FEED Button

Pressing the FEED button over 3 seconds during printing cancels a print job. The current print job is

cancelled. Example: While a 10-label print job is running, you press the FEED button. Two of the labels have

been printed. The print job is cancelled and the remaining eight labels are not printed.

Summary of Contents for 6414 Plus

Page 1: ...User Manual MAN10xxx 01...

Page 2: ......

Page 8: ...User Manual 6414 Plus MAN10xxx 01 3 The Internal View of Printer...

Page 12: ...User Manual 6414 Plus MAN10xxx 01 7...

Page 13: ...User Manual 6414 Plus MAN10xxx 01 8 2 2 Loading and Removing the Ribbon Loading Ribbon...

Page 14: ...User Manual 6414 Plus MAN10xxx 01 9 Note Do not pass the ribbon under the sensor...

Page 22: ...User Manual 6414 Plus MAN10xxx 01 17...

Page 25: ...User Manual 6414 Plus MAN10xxx 01 20 3 3 LCD Interface Function Main Page...

Page 26: ...User Manual 6414 Plus MAN10xxx 01 21 Device Page...

Page 27: ...User Manual 6414 Plus MAN10xxx 01 22 Setting Item in Setting Mode...

Page 28: ...User Manual 6414 Plus MAN10xxx 01 23...

Page 33: ...User Manual 6414 Plus MAN10xxx 01 28...

Page 45: ...User Manual 6414 Plus MAN10xxx 01 40 5 2 Installing the Cutter The Overview of the Cutter...

Page 46: ...User Manual 6414 Plus MAN10xxx 01 41...

Page 49: ...User Manual 6414 Plus MAN10xxx 01 44 Pull open the knob ribbon could be easy to remove...

Page 51: ...User Manual 6414 Plus MAN10xxx 01 46 6 2 Adjusting the print line...

Page 54: ...User Manual 6414 Plus MAN10xxx 01 49 6 5 Adjusting the balance and print head tension...

Page 63: ......