MAN10294

‐

R01

3

4247Z03Plus

‐

QSG

level of the menu.

ENTER

The Enter function is available when the Configuration Menu or

Operator Print Tests Menu is displayed. Pressing ENTER selects the

displayed option. The Enter function is also used during some of the

tests.

LINE FEED

Press LINE FEED to cause the printer to advance the forms one print

line, based on the current LPI setting. If you hold LINE FEED more

than four seconds, the forms move continuously until you release the

key.

PARK/PATH

Pressing this key causes the printer to enter the Park function in either

the ready and not ready state. The continuous forms will backup

(reverse the process direction of) the forms in the forms path.

FORM FEED

This key advances the forms so that the next form is at the top of form

position. The Form Feed function is available when the printer is not

ready.

SET TOP OF

FORM

This should only be used when printing occurred and no Top-of-Forms

commands have been passed to the printer (such as Form Feed or

Printer initialization). The Set Top of Form function is available only

when the printer is not ready, and the paper is loaded to the print line.

This key can be used only for the continuous forms paper sources.

Press SET TOP OF FORM to set the top of form position for

continuous paper sources only.

CANCEL PRINT

When this key is pressed while the printer is active and on line, the

attachment sends a “cancel request” to the host.

For any attachment option, the CANCEL PRINT button clears all print

data and buffers. This function is valid only when the printer is not

ready.

LOAD/EJECT

The LOAD/EJECT function depends on what active form path you

have selected. This section describes the function for each of the

paper paths.

The LOAD/EJECT key performs the following functions:

-Automatically loads forms After the forms are loaded under the

sensor and onto the tractors at the bottom of the forms device press

LOAD/EJECT to automatically load the forms to the top of form

position.

- Moves forms to the tear-off position

STOP

If the printer is in a ready state, press STOP to:

-Make the printer not ready and cause the READY message to

disappear from the operator panel display

-Stop printing as soon as possible without losing print data

-Stop a test if the printer is in test mode

-Stop the printer alarm from beeping

-Allow you to use the other printer function keys If an error condition

appears on the operator panel display, press STOP to:

-Clear the error message from the display

-Stop the printer alarm from beeping.

START

Press START to perform the following functions:

-Make the printer ready and cause the READY message to appearing

the operator panel display.

-Exit the Configuration Menu and make the printer ready. If a partial

reset is required, it is performed to put configuration changes into

effect before the printer becomes ready.

MENU

Use the Menu function key to enter the Configuration Menu. This

function key is valid when the printer is not ready or the printer is ready

and no job is in progress. After you enter the Configuration Menu,

paper movement functions are not available.

Printing the First Document

The Quick Reference is a popular print test that may help familiarize

you with the operator panel keys and the configuration menu you can

set. The Quick Reference printout allows you to check print quality

and printer operations.

1. Each key is listed with a corresponding description to the right.

2. Each parameter is shown with the corresponding values you can

select printed to the right.

3. Ensure that the printer is off line. If the printer is ready, press

STOP

to make the printer not ready

4. Press

TEST

Press

SCROLL/MICRO Up

or

SCROLL/MICRO

Down

until the printer displays:

OPERATOR PRINT

TESTS

Quick Reference

5. Press

ENTER

or

START

to print this test. The READY indicator

comes on and printing begins. Press

STOP

if you want stop the Print

Test before it completes printing.

6. Wait for the printer to stop printing and the READY indicator to go

off.

7. Press

FORM FEED

until you can remove the printout. The printout

should be clear and readable.

YOU HAVE JUST COMPLETED A SETUP AND CHECK OUT OF

THE PRINTER.

We recommend that you now print your printer configuration defaults.

Save this printout for future reference. You can create a printout of the

printer configuration by following these steps:

1.Press

SCROLL/MICRO Up

or

SCROLL/MICRO Down

until the

printer displays:

OPERATOR PRINT

TESTS

Print Customs Sets

To exit Print Test, press

RETURN

to make the printer not ready or

CANCEL PRINT

to make the printer ready.

Press

ENTER

or

START

to print this test. See “Print Custom Sets” in

the User's Guide for more information about this printout.

Configuring the Printer

See the User's Guide on the CD-ROM for information about how to

make and save printer configuration setting changes

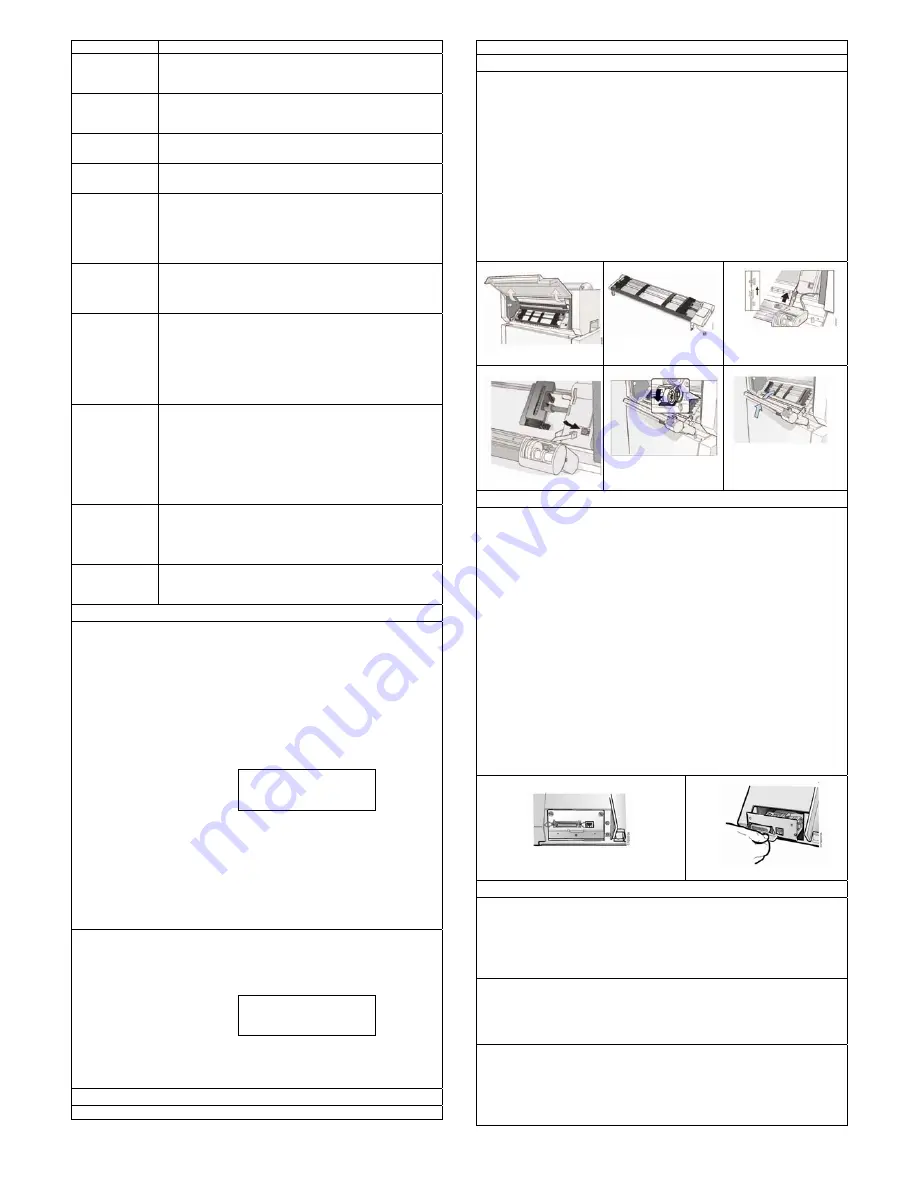

Installing the optional second tractor

A second optional tractor is available for your printer. This tractor may

be installed on the first (standard) front tractor.

1.Open the tractor area cover.

2.Unpack the second tractor.

3.Align the hooks on both sides of the second tractor with the pins on

the first tractor. Push the second tractor on the pins until it is fully

engaged.

4.Connect the second tractor to the first using the electrical

cable/connector provided on the tractor.

5.Rotate the tractor gear protection cover downwards to free the gear.

6.Rotate the second tractor into the closed operating position.

7.To load paper onto the first tractor when the second tractor is

installed, rotate the second tractor outstands insert paper between the

two tractors.

Removing and Installing the Controller Board

The printer is shipped with the controller board already installed.

The following operations explain how to remove the controller and

install a new one into the proper slot in the back of the printer before it

can be used.

Attention

: Do not remove the Controller Board from the protective

package until instructed to do so. Static electricity, though harmless to

you, can damage sensitive Controller Board components.

Attention

: Ensure that the printer is powered off before installing or

removing the Controller Board.

1. Use the screwdriver that came in the Controller Board box to

remove the controller board on the back of the printer by unscrewing

the two screws.

2. Align the left and right sides of the Controller Board with the guides

in the printer and slide it into the slot.

3. Gently push the new Controller Board into the printer until it is

seated in the connector inside the printer. The Controller Board is

correctly seated in the printer when the Controller Board metal plate is

aligned with the back profile of the slot.

4. Firmly fix the Controller Board with the two captured screws using

the screwdriver that came in the Controller Board box.

Maintenance - Cleaning the printer

Periodic cleaning will help keep your printer in top condition so that it

will always provide optimal performance. Before you clean the printer:

1. Turn off the printer.

2. Unplug the power cord.

3. Wait at least 15 minutes for the printhead to cool before starting this

procedure

Cleaning inside the Printer

Every few months, use a soft brush and a vacuum cleaner to remove

dust, ribbon lint, and pieces of paper. Remove the ribbon cartridge to

prevent the ribbon from going into the vacuum cleaner. Vacuum any

dust from around the print head and in the printer cavity.

Cleaning the outside covers

Clean the outside of the printer with a damp cloth and mild soap. Do

not use any spray-type or chemical cleaners anywhere on your printer.

Do not put any liquids or spray near the air vents. For stubborn ink

stains on the cover, use a commercial mechanic's hand cleaner.

Do not use an abrasive cloth, alcohol, paint thinner, or similar agents