5. Extended functions

12

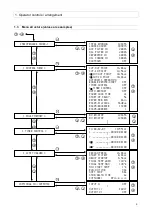

5.2 [ FAULT MEMORY ] sub-menu

Warning messages and faults are stored in the fault

memory. The last warning message or fault recorded is

always at the top. In order to distinguish between faults

and warning messages, faults are marked with

a !

.

You can use

or

to switch between the individual

memory areas in the fault memory.

The faults are displayed as follows:

03! EM-STOP 000100h

a)

b)

c)

d)

a) The same fault has occurred three times.

b) This relates to a fault.

c) Fault has occurred as a result of the emergency off

button being pressed.

d) Fault occurred at 100 running hours.

03 HIGH

TEMP 000100h

a)

b)

c)

a) The same warning has occurred three times.

b) Warning resulting from final compression

temperature being too high

c) Warning occurred at 100 running hours.

The last eight warning messages or faults recorded are

displayed in the fault memory. All messages/faults

occurring before that are however retained in the long-

term memory. The frequency with which a warning or

fault occurs is therefore always recorded.

However you can access more detailed information on

warning messages and faults that have been recorded -

in the fault memory. The following are saved for every

warning message/fault recorded:

- time and date

- compressor status (e.g. on-load)

- final compression temperature, final compression

pressure and network pressure

When accessed, these values flash to clearly show

that they are not the current display values.

To access this information please use

or

to go to

the warning message or fault that you are interested in

in the fault memory. Now press the

key. The day of

the week, date and accurate time are now displayed

(flashing) in the first row. Once the

key has been

pressed again, the status (at the time of the

warning/fault) of the compressor is displayed (flashing)

in the first row. If the

key is pressed again, the final

compression temperature, final compression pressure

and network pressure are displayed (flashing) in the

first display row. The

key then has to be pressed

again.

You are now in the normal fault memory view.

5.3 [ TIMER CONTROL ] sub-menu

Danger

When programming in standby, the machine may

start up at any time.

The timer allows you to switch the machine on and off

at permanently set (programmed) times. You can also

change over the pressure level (e.g. night-time

lowering).

5.3.1 Setting for timer units

You will have already set the time and date as

described in section 2.3. This setting serves as the

basis for accurate timer operations. If you have not yet

set the time and date, please do so now.

Please go to the

[

TIMER

CONTROL

]

sub-menu

where you can use

or

to select from seven

different timer units. The status line of each switching

unit is as follows:

a)

b)

c)

d)

1 _______ 00:00 00:00

a) Unit no.

b) Days of the week

[SMTWTFS]

= Sunday, Monday ..

c) Switch-in point

d) Switch-out point