408-8738

Instruction Sheet

www.commscope.com

Page 4 of 6

5. Crimping Procedure

Before proceeding, refer to the applicable Application Specification: 114-22008 (Category 5E EMT) or

114-13035 and 114-93006 (Category 6 shielded), and ensure the following:

Modular plug and cable are compatible

Cable polarity is properly maintained

Modular plug is properly crimped and assembled

CAUTION:

Make sure that the modular plug shield is fully bottomed onto the body. With some cables

containing shielded twisted pairs, this is especially IMPORTANT to check.

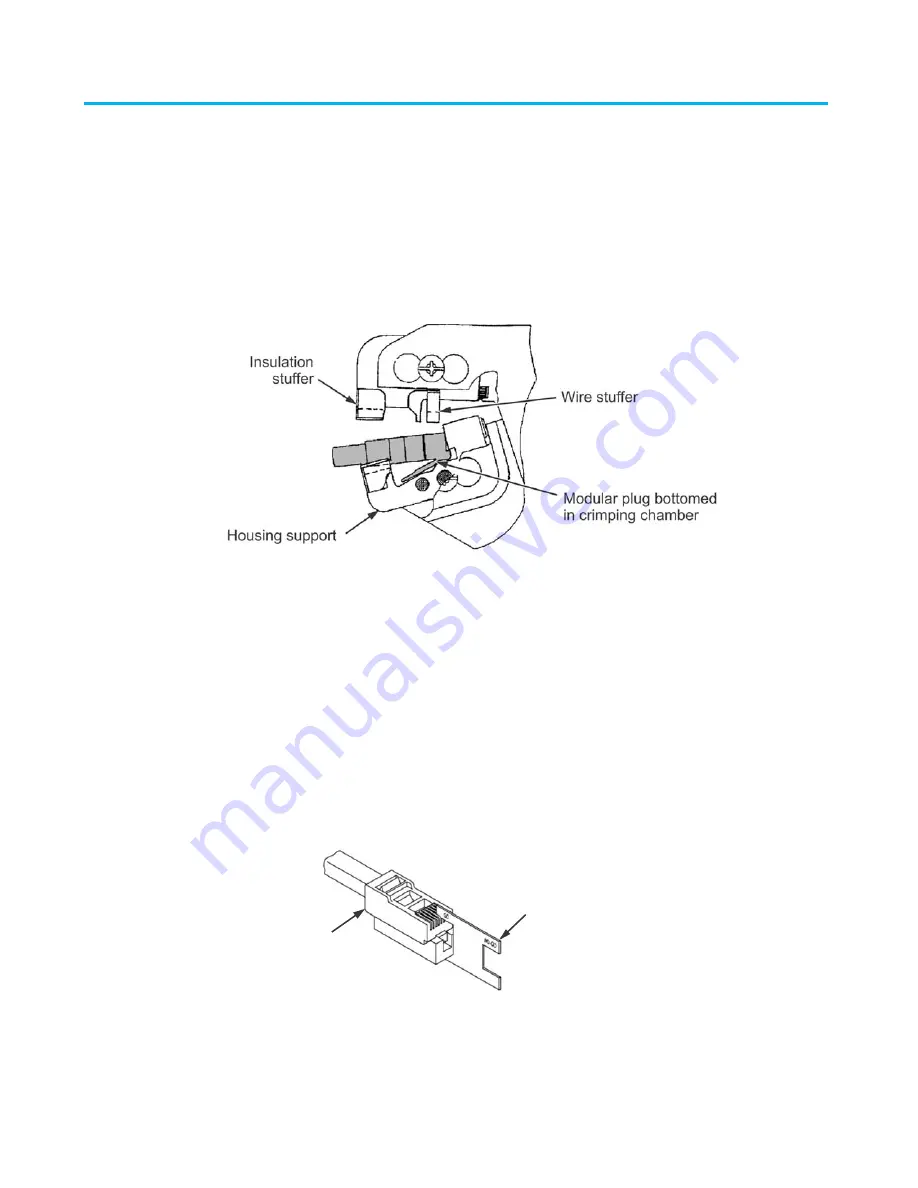

Figure 3. Position of Modular Plug Before Crimping

1. Close the tool handles until the ratchet releases, then allow the handles to open FULLY.

2. Hold the tool so that the back is facing you. Insert the modular plug (including shield and cable) in the crimping

chamber until it bottoms. Refer to Figure 3.

3. While holding the assembly, carefully close the tool handles until the ratchet releases, then allow the handles

to open FULLY.

Note:

This tool terminates three areas of the modular plug. For proper alignment, make sure to apply forward

pressure on the cable while closing the tool handles.

4. Remove the modular plug from the tool, and make sure that the crimp requirements are met according to the

applicable application specification (refer to first paragraph of Section 5).

If necessary, adjust the tool ratchet according to Paragraph 6.1 to obtain the proper crimp height.

Figure 4. Crimp Height Gauge

Note:

Crimp Height Gauge 904170-1 can be used as a quick verification of acceptable crimp height as shown in

Figure 4. Refer to Instruction Sheet 408-4389 for instructions on using the gauge.

Crimp height

gauge (ref)

Modular plug

(ref)