Page 27 of 29

© 2017 CommScope, Inc. All Rights Reserved

14.2. Cleaning DLX connector and adapter

14.2.1. DLX connector cleaning

14.2.1.1. Clean both the optical port adapter and the

drop cable connector (requires accessory kit FHD-ACC-

CLNKIT1) as specified in ADCP-96-163.

14.2.1.2. Examine the end of the drop cable connector,

note the position of the protrusions on the connector.

14.2.1.3. Locate the cleaning tape cassette that is

provided with the cleaning kit.

14.2.1.4. Open the tape shutter by squeezing the lever

on the underside of the cassette and then keep the shut-

ter open by continuing to squeeze the lever.

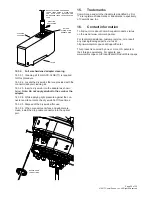

14.2.1.5. Hold connector facing you with the protrusions

perpendicular to the length of the cleaning cassette, tilt

the connector to the right (no more than 8-degrees) this

places the connector in the correct position for cleaning.

Note:

The drop cable connector uses angled SC type

connectors. Make sure the connector end-face is point-

ing in the correct direction before starting the cleaning

motion

.

14.2.1.6. With light pressure, slide the connector end-

face once across the tape in the direction shown using a

smooth linear motion. Do not press too hard and do not

repeat the cleaning motion with the same tape.

14.2.1.7. Release the lever on the underside of the cas-

sette to close the tape shutter.

14.2.1.8. Repeat Step 11.4.2.3 through Step 11.4.2.6 until

the connector has been cleaned three times.

14.2.1.9. When the connector and the adapter are clean,

install the connector into optical port.

CASSETTE

CLEANING

TAPE

DIRECTION

OF CONNECTOR

MOTION

ANGLED CONNECTOR

DETAIL DRAWING

PROTRUSIONS

PROTRUSIONS

14. Maintenance

The maintenance of the indexing terminal installation

includes cleaning :

14.1. HMFOC cleaning

14.1.1. Inspect the complete multi fiber ferrule on the

adapter side as well as on the connector side with a low

resolution microscope as specified in IEC 61300-3-35

with floodlight (side illumination). If dirt is detected, follow

cleaning instructions below.

14.1.2. CommScope recommends dry cleaning first

with a tool such as the US CONEC IBC brand cleaning

tool - MT Series (PN 15639). Follow the cleaning instruc-

tions included with the tool.

14.1.3. To clean the connector on the tail (female, plug,

non-pinned) place the blue plug adapter on the end of the

tool, align the keys of the tool and the connector, rotate

the thumb wheel clock wise two ‘clicks’.

14.1.4. To clean the adapter on the terminal (male,

jack, pinned) place the red plug adapter on the end of the

tool, align the keys of the tool (slot) and the adapter

(square notch), rotate the thumb wheel clock wise two

‘clicks’.

14.1.5. If dry cleaning does not produce the desired

results, use a small amount of solvent on one or more

Chemtronics ® Covenrty ™ 2.5mm fiber optic swabs.

A non isopropyl alcohol (IPA) solvent is recommended

(such as Chemtronix PX Wash). Using the swabs, re-

move contaminates/dirt from the ferrule end face. Always

use a new swab for each connector.

14.1.6. If there is a need to moisten a connector end

face, it must be blown dry with clean compressed air,

then dry clean the connector as detailed described in step

14.1.2 untill step 14.1.4.

14.1.7. After cleaning, inspect the multi fiber ferrule on

adapter and connector side again.