IOM - TRUNNION BALL VALVES, UNIFLOW® BV BT-B9

©COMEV

AL

V

AL

VE SYSTEMS

Technical Dept. Ref. IOM - UNIFLOW BV BT

-B9 - Ed.18/03

Comeval V

alve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly updated data on www

.comeval.es

Page 3

4.4 Technical data – remarks

Check valve selection, material compatibility, pressure and temperature limits and other essential parameters. Ensure

proper safety devices/measures are implemented to prevent exceeding intended use of the product. Contact the ma-

nufacturer for advice in case of pressure tests exceeding the intended use. Refer to Data Sheet for data such as main

features, duties/limits of use, dimensions, weights, etc. and consult the manufacturer for further information.

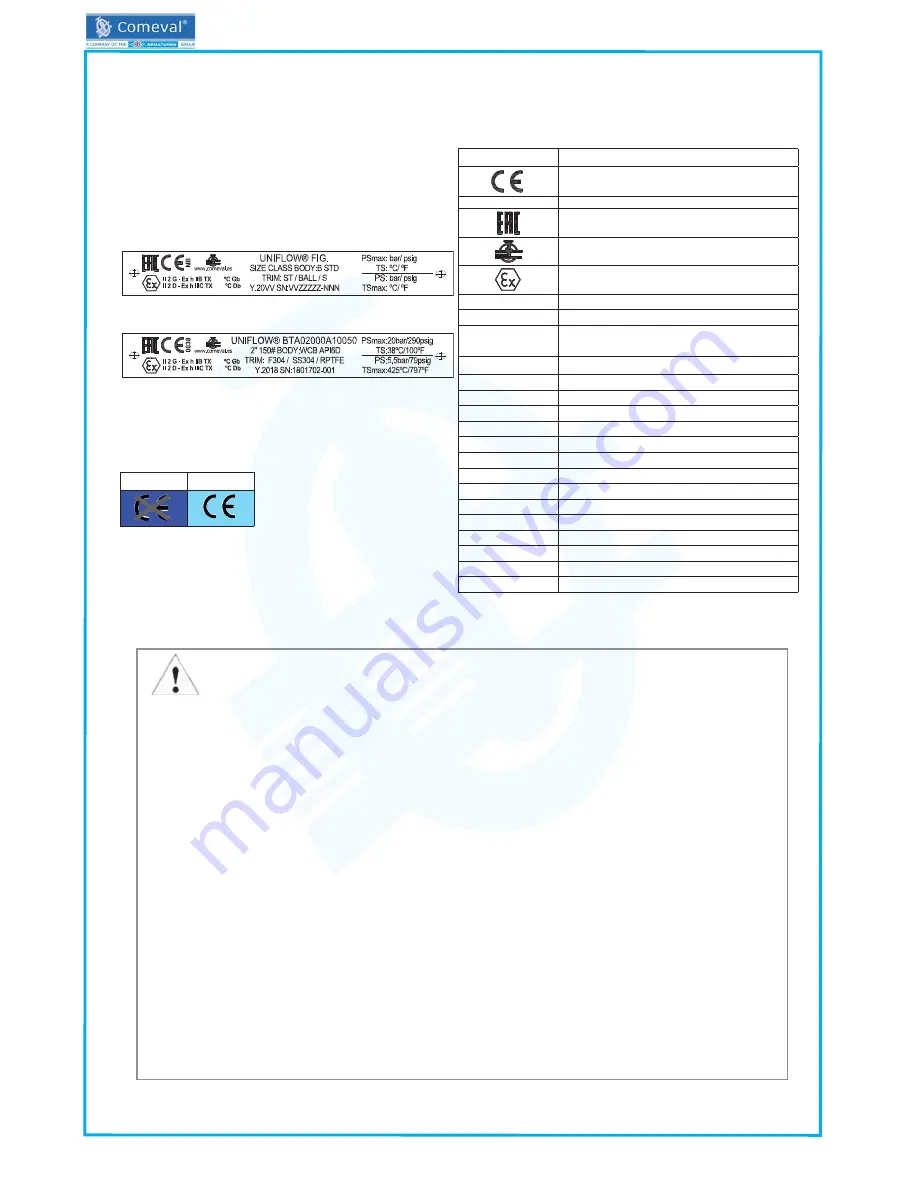

4.5 Marking/nameplate

Nameplate description of the valve:

4.6 marking

* See coding system on Data Sheet.

5. – INSTALLATION

5.1 General remarks on installation

The following points should be taken into account in addition to the general principles governing installation work:

ATTENTION!

- Before installation, make sure previous chapters are thoroughly followed.

- Ensure safe access and working conditions for proper performance.

- Only operate the valve while observing all the safety measures.

- Remove flange covers or any other remaining packing/storage protection if present.

- Lay pipelines such that damaging transverse, bending and torsional forces are avoided.

- Protect valves from dirt during construction work. The interior of the valve and the pipeline must be free of foreign

particles.

- Protect the valve soft parts from heating caused by welding works at the plant during commissioning.

- Avoid mechanical damage to the seats and ball.

- Valves are normally bidirectional. Some special designs are unidirectional, in such a case please follow the arow

in the body for flow direction. Valve optimal position is horizontal with stem pointing upwards. Valves can alterna

-

tively be installed in vertical pipelines. Try to avoid the stem pointing downwards.

- When using the valve as an end seal, the employers’ liability insurance association of the gas and waterworks

specifies the use of a safety precaution such as a plug-in disc, blind flange, etc. With a medium jet that freely exists,

you must secure the exit area.

- Valves should be installed with ball in open position

- When the valve is operated, there is a crushing hazard between the ball and the seats. Ensure the valve is not

under operation in case hands are introduced inside the valve.

- When installing the valve, there is a crushing hazard between valve and pipe system. Mind the hands to avoid it.

Flanged ends valves:

- Make sure that counterflanges are compatible with the standard of the valve flanges. When matching up flanges,

avoid gradients, rotation and pipe misalignment that could cause pipe and valve stress and leakage once installed.

Flanges should fit smoothly. Select the proper flange face gaskets according to duty and centre them on the flange

face properly. Do not force the counterflanges and do not try to tighten the bolts when a gap exists between valve

and pipe or if misalignment is observed. Tighten in a crosswise, moderate and uniform manner.

DN≤25

DN>25

Mark

Description

CE-Marking

NB

Number of notify body

EAC marking (compliance with

TR/CU 032/2013 & TR CU 010/2011)

Manufacturer logo

Explosion protected mark for EU free circulation

(see separate instructions for code)

www.comeval.es

Website of manufacturer

UNIFLOW®

Brand

PED 2014/68/EU

Directive 2014/68/EU

FIG.

Valve code*

SEP

Sound Engineering Practice

Y.20VV

Manufacturing year

SN: VVZZZZZ-N

Batch / Serial no.

SIZE

Valve size

CLASS

Valve class

B

Body material

STD

Main manufacturing standard

ST

Stem material

BALL

Ball material

S

Seat material

PSmax

Max. pressure

TS

Max. temperature at max. pressure

PS

Max. pressure at max. temperature

TSmax

Max. temperature