IOM -

SELF-ACTING DIAPHRAGM VALVES

MAXOMATIC VMXBERL24C

©COMEV

AL

V

A

L

VE SYSTEMS

T

echnical Dept. Ref. IOM-SELF-ACTING DIAPHRAGM V

A

L

VES, MAXOMA

TIC VMXBXERL24C-Ed.15/05

Comeval V

alve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly u

pdated data on www

.comeval.es

8. – TROUBLESHOOTING

In the event of malfunction or faulty operating performance, check that the installation and adjustment work has been

carried out and completed in accordance with this Manual.

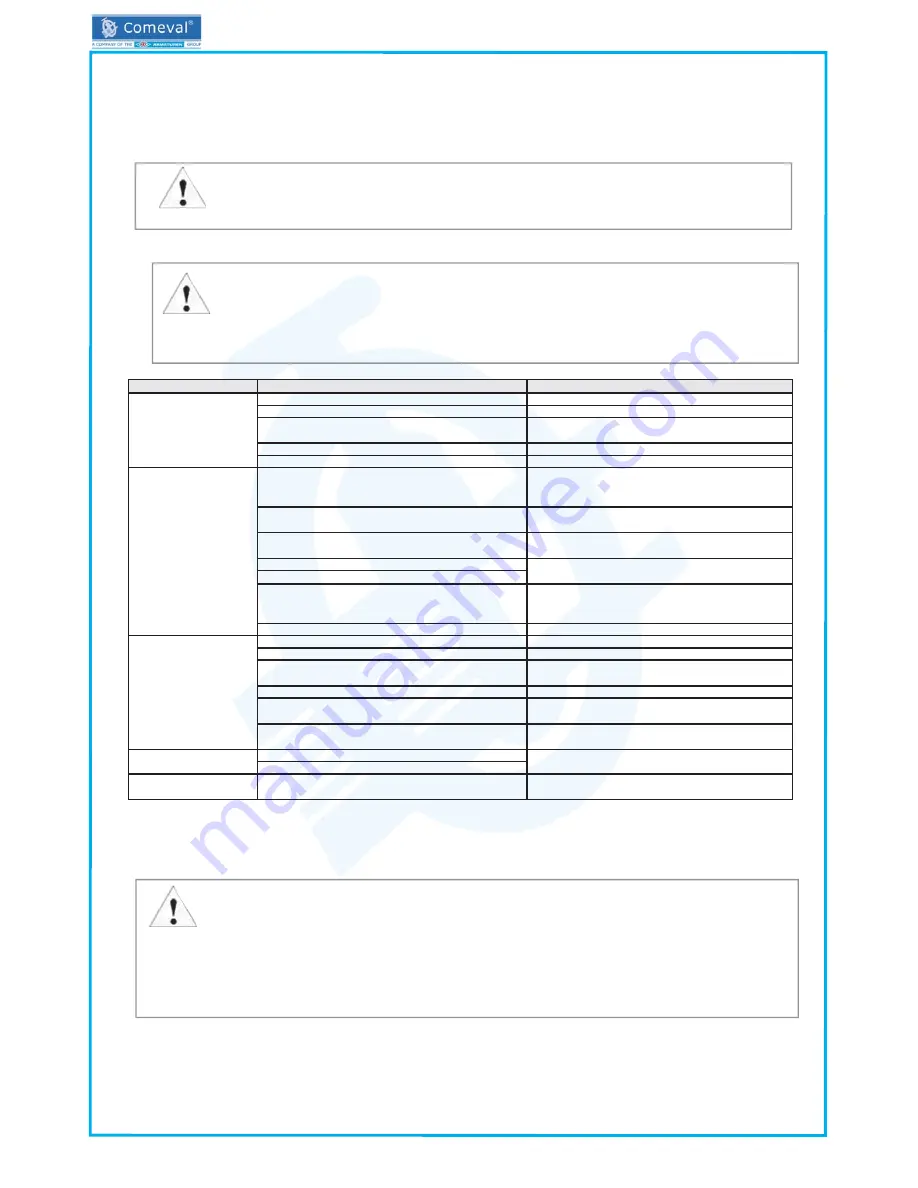

9. – TROUBLESHOOTING TABLE

FAULT

POSSIBLE CAUSE

CORRECTING MEASURES

No fl ow

Not enough fl ow

-Flange covers or protection not removed.

-Clear valve entrances.

-Isolating valves of Pilot circuit or of pipeline closed.

-Open the valves.

-Normal pipeline pressure is not enough to overcome

diaphragm rigidity.

-Check pipeline pressure in relation to selected dia-

phragm and the condition of the diaphragm itself.

-Piping clogged.

-Check piping system.

-Solenoids calcifi ed or with impurities.

-Check the Solenoid clean or replace if needed.

Valve is not closing or is

not tight at closing

-The Pilot is not operating correctly or is not well ad-

justed. The Pilot does not stop the drainage of the

activation chamber (observe the exhaust of the Pilot).

-Check the closing with the manual valve or with the

Solenoid valve if any.

-Check adjustment and condition of the Pilot. Chan-

ge if needed.

-Dirt/deposits trapped between the diaphragm and

body seat.

-Open and close again trying to eliminate dirt trap-

ped.

-Diaphragm damaged.

-Disassemble and inspect the body and diaphragm,

clean or replace parts.

-Body seat wear.

-Strainer or Pilot circuit clogged.

-Check if the fl uid reaches the activation chamber,

by unplugging the corresponding connection. Revise

fi ltering and Pilot circuit.

-Solenoids calcifi ed or with impurities.

-Check the Solenoid core, clean or replace if needed.

Valve is not regulating

properly

-Pilot is not well adjusted.

-Check tightening of Pilot adjusting screw.

-Valve is oversized.

-Check valve sizing.

-The adjusting point is out of the Pilot adjusting range

or out of the diaphragm working range.

-Check operation conditions in relation to Pilot and

diaphragm.

-Strainer or Pilot circuit clogged.

-Check fi ltering and Pilot circuit.

-Pilot working failure.

-Tighten/loosen the Pilot adjusting screw to observe

if there is any reaction. Inspect/replace it if needed.

-Opening/closing speed not suitable (large size val-

ves with accelarator Pilot).

-Check adjustment of adjusting screw of accelerator

Pilot.

Broken fl ange

-Bolts not properly tightened.

-Realign piping and fi t new valve.

-Mating fl anges not properly aligned.

Leakage between body

and cover

-Cover bolts loose or diaphragm damaged.

-Retighten bonnet bolts or change diaphragm.

Technical support always available through our website www.comeval.es or your local distributor.

10. – DISMANTLING THE VALVE OR THE COVER

Page 7

ATTENTION!

- Read chapters 10 & 11 before carrying out installation and repair work!

- Read chapter 6 before recommissioning!

ATTENTION!

The following points must be observed:

- Pressureless pipe system

- Medium must be cool

- Plant must be drained

- Purge pipe systems in case of toxic, corrosive, fl ammable or caustic media

ATTENTION!

- It is essential that the safety regulations are observed when identifying faults.