COLUMBUS

McKINNON

15

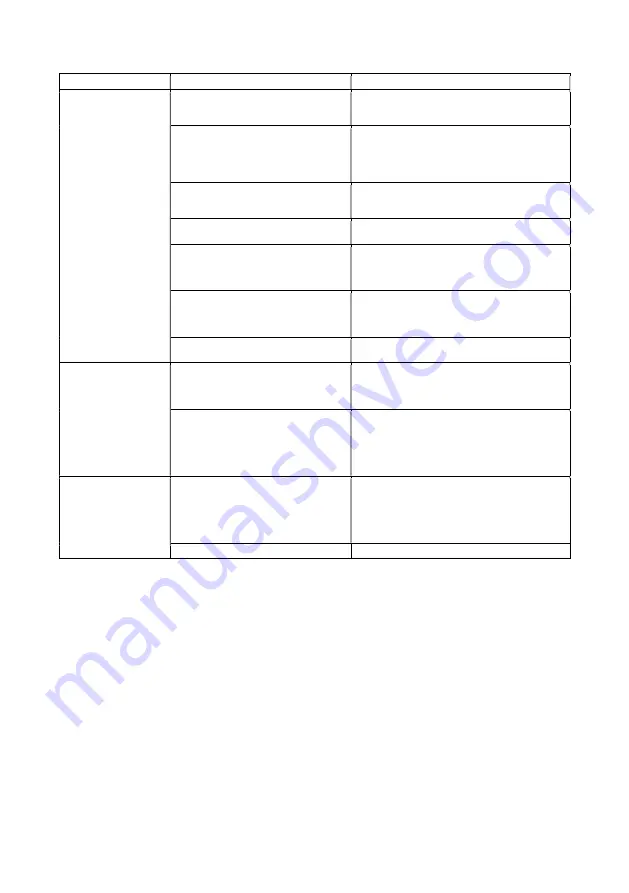

Troubleshooting chart

Symptom

Possible cause(s)

Corrective action

Hoist is hard to operate in

either direction.

1. Load chain worn long to gauge, thus

binding between liftwheel and chain

guide.

1. Check chain, and replace if worn excessively.

2. Load chain rusty, corroded or clogged

with foreign matter such as cement or

mud.

2. Clean chain by tumble polishing or using a

non-acid or non-caustic type solvent. Check

chain for gouges, damaged or bent links. Lubricate

with Lubriplate® Bar and Chain Oil 10-R (Fiske

Bros. Refning Co.) or equal lubricant.

3. Bushings clogged with matter such as

cement or dust.

3. Disassemble and clean liftwheel bushings and

bushings in gear cover and side plate (gear side).

Any parts worn excessively should be replaced.

4. Lever binding.

4. Clean by removing any foreign matter which may

be between the lever and the brake cover.

5. Brake parts corroded or clogged with

foreign matter.

5. Disassemble brake and clean thoroughly (by

wiping with a cloth - not by washing in a solvent).

Replace ratchet assembly if too gummy, worn or

scored. Keep brake surfaces clean and dry.

6. Liftwheel pockets clogged with foreign

matter or worn excessively causing chain

to bind between liftwheel and chain

guide.

6. Clean out pockets and use if not worn excessively.

Replace liftwheel if pockets are worn.

7. Liftwheel twisted or bent - gear teeth

bent.

7. Excessive overload had been applied. Replace

damaged parts.

Hoist is hard to operate in

down direction.

1. Brake parts corroded or clogged with

foreign matter.

1. Disassemble brake and clean thoroughly (by

wiping with a cloth - not by washing in a solvent).

Replace ratchet assembly if too gummy, worn or

scored. Keep brake surfaces clean and dry.

2. Chain binding.

2. Check chain, and replace if worn excessively.

Clean chain by tumble polishing or using a

non-acid or non-caustic type solvent. Check chain

for gouges, damaged or bent links. Lubricate with

Lubriplate® Bar and Chain Oil 10-R (Fiske Bros.

Refning Co.) or equal lubricant.

Hoist is hard to operate in

up direction.

1. Chain binding.

1. Check chain, and replace if worn excessively.

Clean chain by tumble polishing or using a

non-acid or non-caustic type solvent. Check chain

for gouges, damaged or bent links. Lubricate with

Lubriplate® Bar and Chain Oil 10-R (Fiske Bros.

Refning Co.) or equal lubricant.

2. Overload.

2. Reduce load or use correct capacity unit.

Summary of Contents for Yale ERGO 360

Page 19: ...COLUMBUS McKINNON 19 EXPLOSION DRAWING YaleERGO 360 0 8t 1...

Page 21: ...COLUMBUS McKINNON 21 EXPLOSION DRAWING YaleERGO 360 1 6t 1...

Page 23: ...COLUMBUS McKINNON 23 EXPLOSION DRAWING YaleERGO 360 3 2t 1...

Page 25: ...COLUMBUS McKINNON 25 EXPLOSION DRAWING YaleERGO 360 6 0t 2...

Page 27: ...COLUMBUS McKINNON 27 EXPLOSION DRAWING YaleERGO 360 9 0t 3...

Page 32: ......

Page 33: ...YaleERGO 360 85005206AC 2019 05...

Page 36: ...4 COLUMBUS McKINNON 10 50 0 C 2 3 WLL...

Page 37: ...COLUMBUS McKINNON 5...

Page 38: ...6 COLUMBUS McKINNON...

Page 39: ...COLUMBUS McKINNON 7 0...

Page 40: ...8 COLUMBUS McKINNON 800kg 3200kg 6000kg 9000kg a N b c 30 60 d...

Page 41: ...COLUMBUS McKINNON 9 30 45 ERGO...

Page 42: ...10 COLUMBUS McKINNON Yale 25 15...

Page 45: ...COLUMBUS McKINNON 13 12 1 10 5...

Page 48: ...16 COLUMBUS McKINNON 0...

Page 50: ...18 COLUMBUS McKINNON COLUMBUS McKINNON 1 2 3...

Page 51: ...COLUMBUS McKINNON 19 YaleERGO 360 0 8t 1...

Page 53: ...COLUMBUS McKINNON 21 YaleERGO 360 1 6t 1...

Page 55: ...COLUMBUS McKINNON 23 YaleERGO 360 3 2t 1...

Page 57: ...COLUMBUS McKINNON 25 YaleERGO 360 6 0t 2...

Page 59: ...COLUMBUS McKINNON 27 YaleERGO 360 9 0t 3...

Page 64: ......