4

COLUMBIA SPECIFICATIONS

800.626.2117

columbiasinks.com

info@

columbiasinks.com

©2021 Columbia Products

CARE AND MAINTENANCE

Care and Maintenance

Regular cleaning will preserve the appearance and integrity of the surface. Stainless steel can

easily be cleaned and kept stain-free using various methods.

Recommendations:

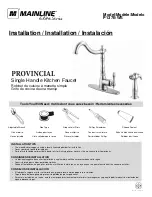

• Clean with an abrasive cleaner like, Bon-Ami or Zud weekly or bi-weekly. Always scrub in the

direction of the grain or polish lines. Another option is to use Baking soda. Make sure to

rinse well and dry. Illustration A

• Most soaps and detergents contain chlorides, we recommend rinsing the stainless-steel

sink with hot water after use, to prevent corrosion. Illustration B

• Regularly dry your sink to prevent water and surface rust marks. Illustration C

• Do not leave salt in the sink or near a saltwater environment.

• Use a quality stainless steel cleaner and follow cleaner instructions. Wipe along the grain

(NOT against). Illustration D

Things to Avoid:

• Avoid harsh abrasive cleaners and corrosive chemicals.

• Avoid abrasive scouring pads, carbon steel brushes and steel wool for cleaning as iron

particles left behind can lead to rust.

• Avoid the use of oily rags or greasy cloths when wiping the surface. To avoid water spots,

wipe dry after use.

Additional Tips:

• Regularly drying your sink works wonders to prevent water and surface rust marks.

• Wear rubber gloves when working with cleaners to protect your hands.

• Never mix cleaners. Some products react to create dangerous gases.

• There are thousands of blended or compound cleaners on the market. Users are advised to

contact suppliers of solvents for information on their applications on stainless steel.

• DO NOT USE SOLVENTS in closed spaces or while smoking.

• Note: Columbia does not recommend use with harsh chemicals.

Illustration A

Illustration B

Illustration C

Illustration D