www.colmac.ie

8

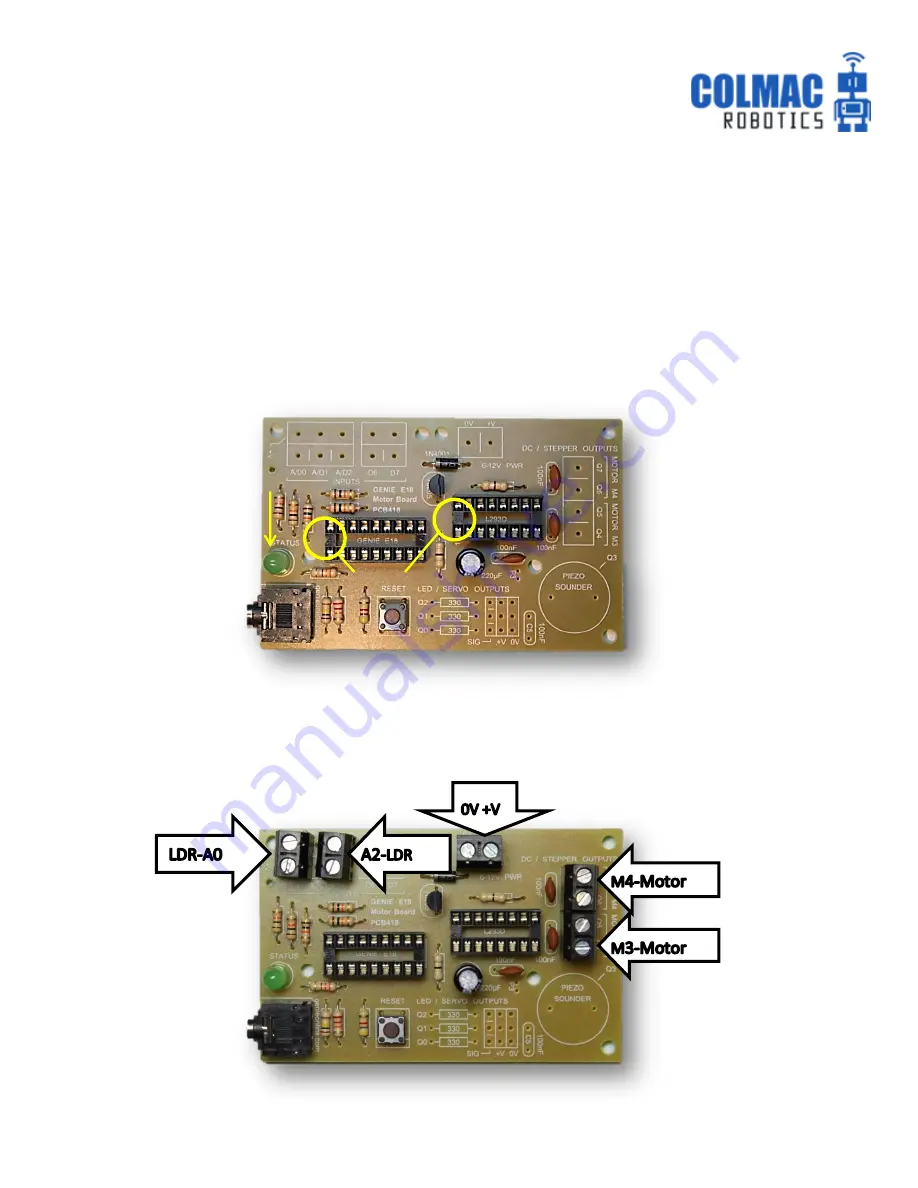

Step 5: Solder the status LED and chip sockets

Insert the green status LED as shown below – flat side is negative.

The chip sockets to hold the GENIE E18 microcontroller and L293D motor driver microchips should

be inserted as shown. The L293D chip allows the motor turn both clockwise and anti-clockwise

which gives forward/reverse and turning motion in the line follower robot.

Step 6: Solder the cable terminal blocks.

Insert the terminal blocks as shown – arrows indicate where flying lead cables will be inserted.

Notch

Flat side -