A D J U S T A R M T O S U I T

W E I G H T O F M O N I T O R

8

F O L D

F O L D

F O L D

Turn adjuster screw

until monitor ‘floats’

in all height positions

U S E F U L T I P

Adjustment will be easier and more precise if

arm is positioned as shown below whilst adjusting

8A

The arm setting indicator

allows for quick installation

of multiple monitors

You can quickly ‘dial in’ to

the same setting, then if

necessary, fine tune the

adjustment to balance the

monitor

8B

Ca.

Ca.

-

Lighter

monitors

Use 6mm

Allen Key

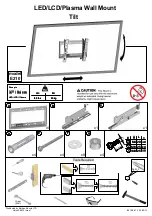

F I X I N G P O S T T O D E S K O P T I O N S

1

UNI/CSG100/K

UNI/CSG50/K

DESK CL AMP

A

THROUGH DESK

B

Cast Grommet

Back

of desk

C

CAST GROMMET

Follow one

of the Desk and

Post fixing options

described below

UNI/50S12/K

UNI/100S12/K

A S S E M B L E P O S T M O U N T C O M P O N E N T S

2

F I T M O N I T O R A R M

O N T O C L A M P B R A C K E T

4

M O U N T M O N I T O R T O A R M

6

Screws under-

inserted

I M P O R T A N T

It is the responsibility of the installer to ensure all mounting

screws are properly engaged with a minimum of 4 x 360˚ turns

into the display. Under or over insertion may cause damage to

the equipment or injury to personnel.

M A X

SCREEN WEIGHT

9KG/19.8LB

Use screws supplied

4 x

4 x

A T T A C H M O N I T O R M O U N T

P L A T E T O M O N I T O R

5

I M P O R T A N T

Raise arm to uppermost position before removing monitor

otherwise it may spring up when unloaded

Screws over-

inserted

T O R E M O V E M O N I T O R

7

I M P O R T A N T

Ensure you leave enough

free cable to avoid

stretching or snagging

at all positions

I N S T A L L M O N I T O R C A B L E S I N T O

C A B L E M A N A G E M E N T F E A T U R E S

9

Install plastic

bush

Ensure the washer is

orientated correctly

for required 90°

stop position

No 90° stop

function

For 90°

stop

function

I M P O R T A N T

Refer to individual

instructions

UNI/SMC

UNI/LCLM38

UNI/TAC

UNI/HLC

I M P O R T A N T

Please see compatibility table overleaf

for guidance on recommended

desk fixings

Install optional security

screw if required

6B

6A

90°

90°

+ Heavier

monitors

Install

Grub screw

to secure

3B

Install Clamp

bracket to

Post

3A

See also step if 90⁰ stop needs

to be reconfigured or removed

2

A T T A C H C L A M P B R A C K E T T O P O S T

3

Go straight to step

See also step

before continuing to step

Ensure that stud is fully

screwed into post before

installing

30mm

Approx

S I N G L E

C O N F I G U R A T I O N

D U A L

C O N F I G U R A T I O N

2

2

11

P R I N T S I Z E - A 3 4 2 0 M M X 2 9 7 M M

FOLD

FOLD