10

Caution!

Keep all objects clear of the drive roller when you press the

FEED

button.

4.

Confirm that the label taken sensor is unobstructed. Clean away

any obstruction with a soft brush if necessary.

5.

Load media as required, or if there is already media in the printer,

lower and lock the printhead and press the

FEED

button once.

Cleaning the cutter

WARNING!

Don’t clean the cutter with the printhead down. Turn the

printer

OFF

and raise the printhead first.

Never

push objects

into the front of the printer while the printhead is down.

Clean the cutter with 98% to 99% pure isopropyl or denatured alcohol

and cotton tipped swabs as follows:

1.

Confirm that the printer is turned

OFF

, then open the media cover.

2.

Press the two printhead releases toward the rear of the printer to

unlock the printhead. Lift the printhead until it is fully raised.

3.

Remove any installed label media.

4.

Using a cotton swab moistened with alcohol, clean all dirt and

label residue from the cutter bar and the cutter rotary blade.

5.

Check the paper path for label debris or obstructions. Clean the

paper path as required.

6.

Reinstall the label media.

7.

Lower the printhead and press it down until it locks closed.

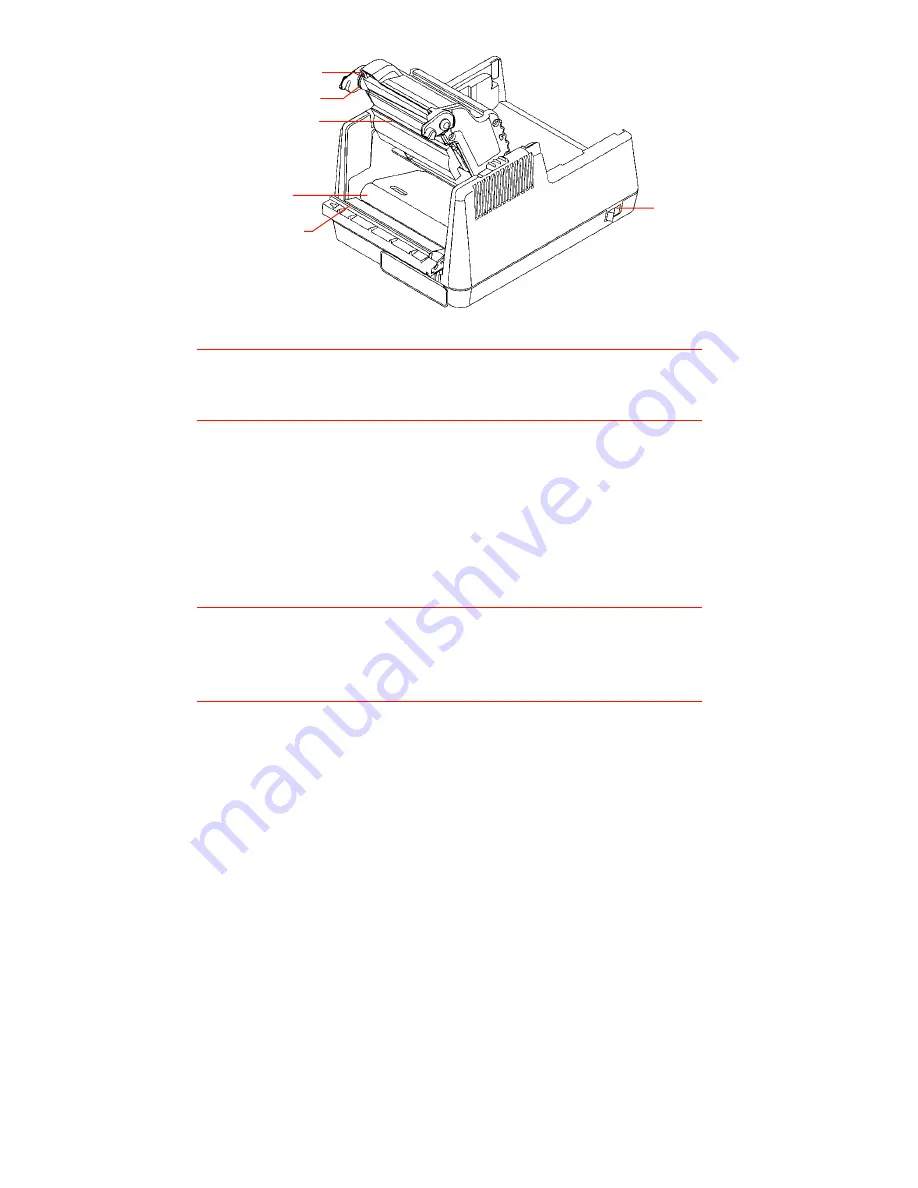

Figure 5. Printer open for cleaning

Label taken sensor

Cutter rotary blade

Printhead

Cutter bar

Drive roller

Power switch