Connecting the Power and I/O Breakout Cable

CAUTION

:

To reduce emissions, connect the far end of the Breakout cable shield to frame ground.

Note

:

l

Perform wiring or adjustments to I/O devices when the vision system is not receiving power.

l

You can clip unused wires short or use a tie made of non-conductive material to tie them back. Keep bare

wires separated from the +24VDC wire.

1. Verify that the 24VDC power supply is unplugged and not receiving power.

2. Attach the Power and I/O Breakout cable's +24VDC and Ground wires to the corresponding terminals on the

power supply. For more information, see

3. Attach the Power and I/O Breakout Cable's M12 connector to the vision system's 24 VDC connector.

4. Restore power to the 24VDC power supply and turn it on if necessary.

Indicator LEDs

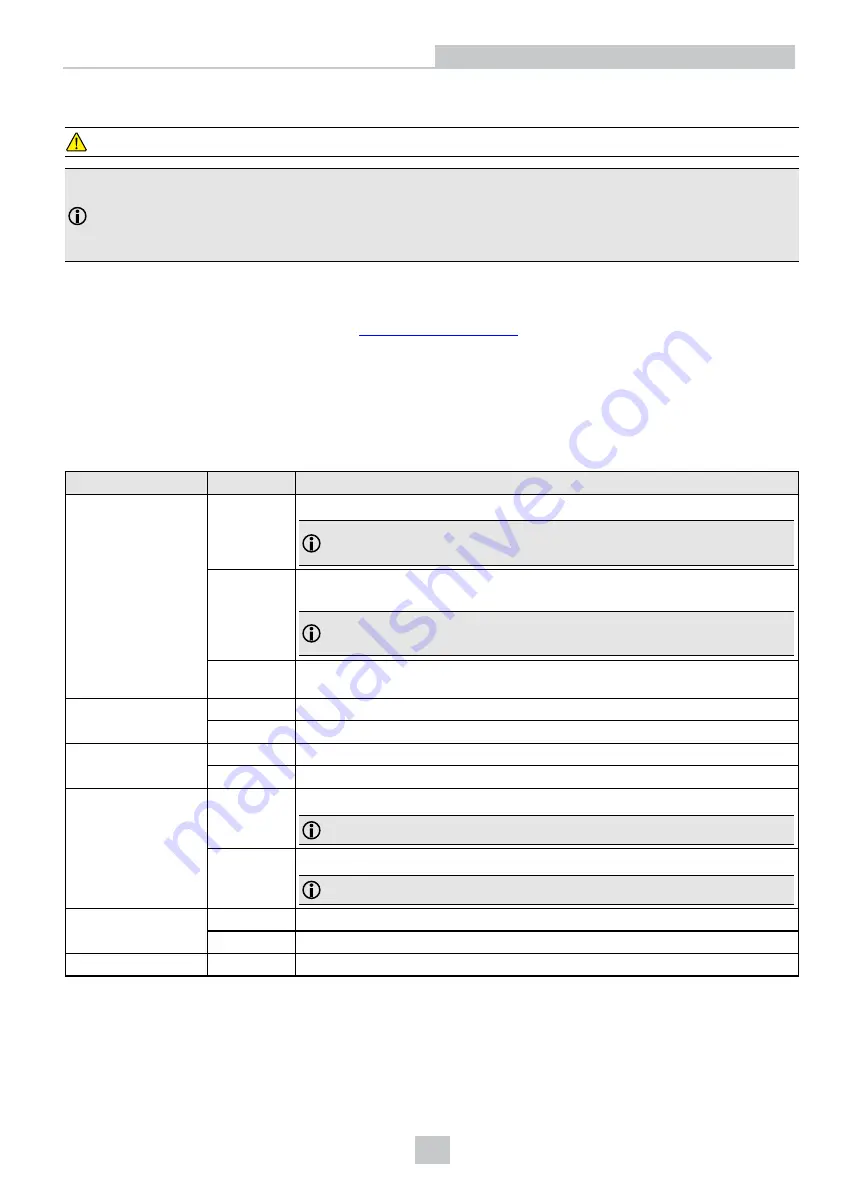

The table summarizes the functions of the In-Sight 2800's indicator LEDs.

Indicator

Color/Status

Meaning

User indicator LEDs

GREEN,

blinking

Light edges blink in green when the device performs a good read.

Note

: In case of a good read, the Good/Bad read indicator LED is also

blinking in green.

RED,

blinking

Light edges blink in red when the device performs a bad read when it does not

find a decoding after a timeout.

Note

: In case of a bad read, the Good/Bad read indicator LED is also

blinking in red.

WHITE

Light edges are white when you trigger the Identify function in In-Sight. For more

information, see In-Sight Reference Manual.

Power indicator LED

ON

The device is on.

OFF

The device is off.

Train/Trigger status

indicator LED

ON

If the device has a trained code, this LED is green.

OFF

If the device has no trained code, this LED is off.

Good/Bad read

indicator LED

GREEN,

blinking

The device performs a good read.

Note

: In case of a good read, light edges are also blinking in green.

RED,

blinking

The device performs a bad read when it does not find a decoding after a timeout.

Note

: In case of a bad read, light edges are also blinking in red.

Communication

ON

This LED is on when the In-Sight 2800 established the Ethernet connection.

OFF

This LED is off when there is no Ethernet connection.

Error

ON

This LED is on if the In-Sight 2800 detects an error.

35