ENGLISH

28

TECHNICAL MANUAL

8. MACHINE COMPONENTS

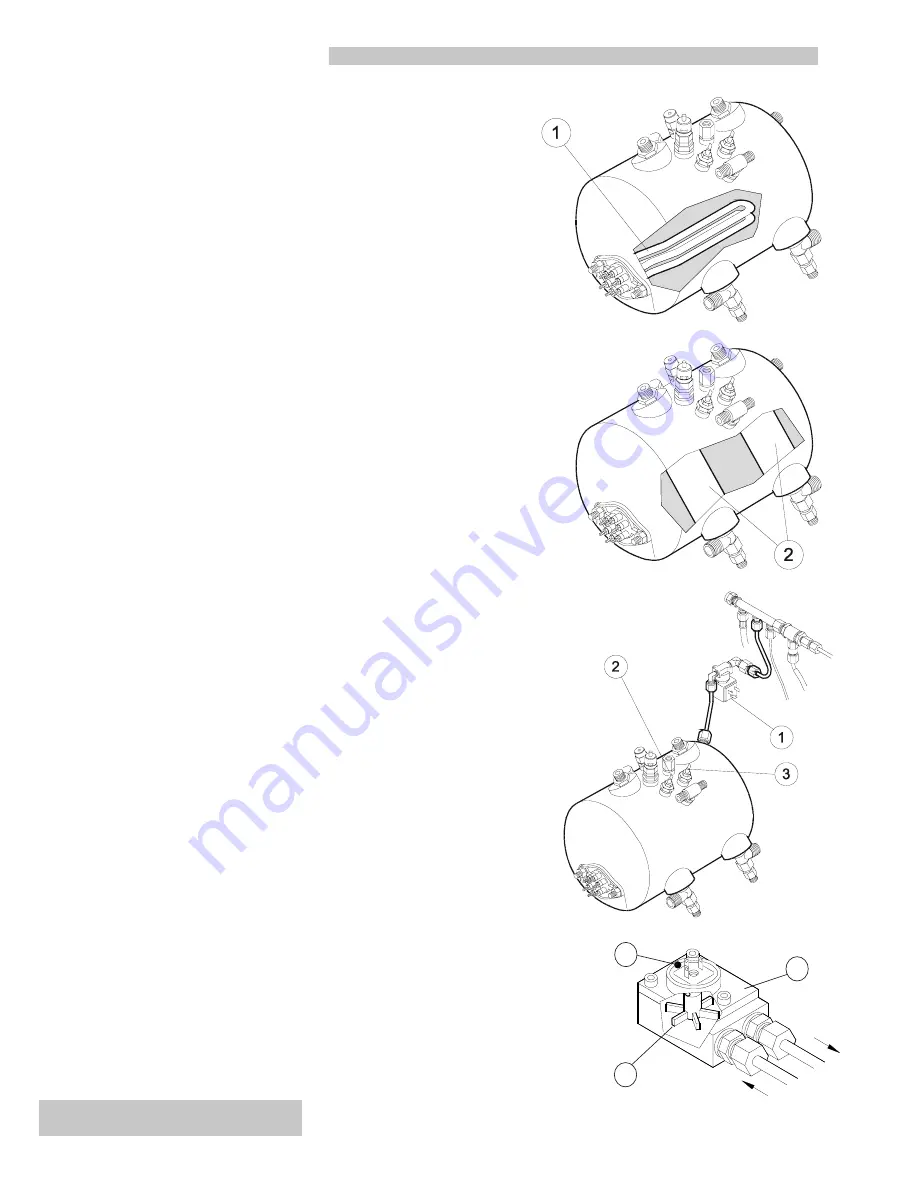

8.1 Boiler

The boiler is made to copper plate inside which the heat exchangers and the

electric heating element (

1

) are housed. The heating element heats the water in

the boiler.

Water to make coffee is taken from the heat exchanger while it is taken from

the boiler if hot water is wanted. Steam is taken from the top of the boiler.

8.2 Heat exchanger

The heat exchangers (

2

) make it possible to heat the water up to an ideal

temperature for a perfect cup of espresso coffee.

The heat exchangers function is to produce an exchange of thermal energy

between the water inside it and the water inside the boiler.

This component cannot be replaced.

8.3 Automatic Water Inlet

The AEA system (automatic water inlet) is used to control boiler level. It

consists of:

l

a working level probe (

3

);

l

a minimum safety level probe (

2

);

l

an electronic level regulator in the electronic control unit;

l

a hydraulic circuit with a solenoid valve (

1

) controlled by the control unit.

The level probes act as a pole in the low voltage electrical circuit: when

the level of the water drops the circuit interrupts itself and the electronic

control unit sends an impulse to the AEAs solenoid valve (

1

) and to the motor

pump which sees to the automatic fillng up with water, keeping the level in the

boiler constant.

8.4 Volumetric doser

The volumetric doser (

5

) measures the quantity of water sent to the unit for making

espresso coffee.

It consists of a Hall-effect type turbine (

6

) which, by turning, generates an electric

impulse that is sent to the electronic control unit.

This impulse is read by the control unit and stored during dose programming.

Each flash of the LED (

4

) on the volumetric doser indicates that the doser is working

properly.

6

4

5

All manuals and user guides at all-guides.com