M03Q40G6-03 30/07/08

pag

31

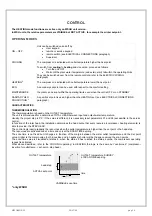

SET-POINT COMPENSATIONS

The compensations are evolved functions to protect the compressors and to adapt, as far as possible, the unit operating to the

installation and use characteristics.

The compensations prolong the compressor operating time and limit the start number; to do this they delay the compressor

insertion point adding an offset.

COMPENSATED compressor activation point

non compensated compressor activation point

s

o

e

O

offset by compensation

ACTUAL set point

•

The compensation on the DURATION is useful when the installation water content is limited.

•

The compensation on the CHARGE is useful if the variable charge is present.

For the enabling and the configuration is necessary the parameter modification with reserved access to the service centres.

In industrial applications where is requested a temperature check is possible to disable the COMPENSATIONS.

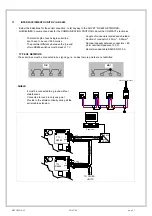

SET-POINT CORRECTIONS

The correction aim is to optimize the unit energetic efficiency.

To do this the corrections modify the set point in a dynamic way in function of determined variables: for example in summer

operating with low external temperatures, so with a reduced charge, is possible to obtain the internal comfort also with set

point higher than standard, obtaining an higher energetic efficiency.

CORRECTION

ACTUAL or correct set point

(visible at status 1)

static

set point

The static set point can so be modified in a dynamic way by two CORRECTIONS based on as many unit external factors:

•

correction based on the ext. temp. / enthalpy

•

correction based on the Water reset (4-20 mA signal provided by the Client)

The correct set point, to whom have been summed or removed the corrections, is named ACTUAL set-point and it is visible at

status n°1.

The STATA menu visualizes the compensation value on the ext. temperature (status 5) and WR (status 6)

For further details see the ELECTRICAL CONNECTIONS section.

CIRCULATION PUMP

The pump is always activated with the units ON.

The delivery capacity is variable to soften the thermal shock to the compressors when the plant temperature is close to the

threshold limits.

Delivery capacity depends on the intake temperature:

•

SUMMER: high water temperature reduces delivery

•

WINTER: low water temperature reduces delivery

CIRCULATION PUMP – CONDENSER (RUNNING WATER)

The pump is started BEFORE the compressor start and stopped AFTER the condenser stop.

SET POINT

SET POINT

SUMMER - WINTER

The thermoregulator manages two set points:

•

SUMMER set-point for cooling (parameter 32)

•

WINTER set-point for heating (parameter 33)

The control is performed on the OUTLET TEMPERATURE, comparing it with the actual set-point value (visible at status 1).

SET-POINT CALCULATION:

•

desired medium outlet water temperature = 7°C

•

Project temperature differential = 5°C (that is inlet water = 12°C)

•

¼ of the project temperature differential = 5 / 4 = 1.25°C

•

set-point to be set = 7 – 1.25 = 5.7°C