23

Note: Never operate saw without bearing cover in place.

For normal conditions the grease should conform to the NLGI grade two consistency

and be free of any chemical impurities such as free acid or free alkali, dust, rust, metal

particles or abrasives.

For best results, the bearings should be lubricated while in operation.

Note:

Due caution for personal safety must be observed when servicing rotating

equipment.

If necessary to lubricate while the bearing is idle, refer to lubrication table for the

maximum grease capacity for the bearings.

LUBRICATION OF SEALMASTER BEARINGS

Shaft Sizes

Maximum Grease Capacity of Bearing

Chamber in Ounces

1/2" to 3/4"

.09

7/8" to 1-3/16"

1/4

1-1/4" to 1-1/2"

3/8

1-11/16" to 1-15/16"

3/4

2” to 2-3/16"

1-1/8

E. Pump

The submersible pump is mechanically driven by the V-belts and the sealed bearings

require no lubrication. The pump is designed to run wet or dry, but for continued dry

cutting, disconnect the pump.

1. Be sure to keep the pump clean - do not allow sediment to cake in the pump and

clog it.

2. Keep all lines clean and running free.

3. Do not allow the Flex-cable to be pinched by the blade guard or anything else.

Damage to the flex cable by pinching is not covered under any warranty

Summary of Contents for BBC157

Page 1: ...OWNERS MANUAL COMPACT MASONRY SAW MODELS BBC157 BBC207 BBC547 FORM 7506 rev 2 2006...

Page 25: ...25 V PARTS LIST SECTION Power Plant BBC547 Gasoline S 1 S 2...

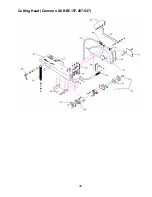

Page 28: ...28 Frame Common All BBC157 207 547...

Page 30: ...30 Cutting Head Common All BBC157 207 547...

Page 32: ...32 Cutting Table Common All BBC157 207 547...

Page 34: ...34 C Baldor Service Policy...

Page 35: ...35 D Honda Service Policy...