POWER GUN SUCTION BLAST TOOLS

Page 4

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24189, Rev. C 06/18

3.0 SETUP

3.1 General

Setup

3.1.1

An air filter is recommended in the air supply to

remove condensed moisture from the air line.

3.1.2

Connect the Power Gun’s air hose to a 3/4” or

larger air supply line. An isolation valve is required at the

air source to enable depressurization.

3.1.3

Secure all compressed-air supply hose

connections with safety lock pins and safety cables to

prevent accidental disconnection. Lock pins and safety

cables are listed in Section 9.1.

WARNING

Hose disconnection while under pressure can

cause serious injury or death. Use safety lock

pins or safety wire to lock twist-on claw type

couplings together and prevent accidental

separation, and safety cables to prevent hose

from whipping should separation occur

.

3.1.4

Make sure the setscrews securing the nozzle,

jet, and gun assembly are tight.

3.2

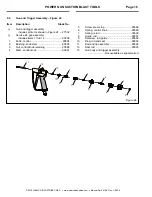

Water Connection (H2O Model), Figure 5

3.2.1

Connect the water hose to a water faucet.

3.2.2

Make sure the water valve is in the OFF

position, handle perpendicular to the valve.

Figure

5

3.2.3

Loosen the air-induction tensioning knob and

rotate the sleeve to close the induction port. Tighten the

knob to secure.

3.2.4

Connect the water hose to a faucet; use a

garden hose if additional hose is needed.

3.2.5

Open the faucet to supply water to the Power

Gun.

3.2.6

Begin dry blasting per Section 4.5. After dry

blasting adjustments are made, open the water valve as

needed to regulate water flow. Open the valve only

enough to water to suppress dust and prevent it from

being airborne.

4.0 OPERATION

NOTE: Unless noted otherwise, the sequence of

operation in Sections 4.1 through 4.4 may be done in

any order that is best suited for the application.

4.1

Start Compressed Air Supply

4.1.1

For onsite blasting, locate the compressor

upwind and away from the blasting operation.

4.1.2

Make sure that all compressed-air supply-hose

claw-type couplings are secure with safety lock pins and

safety cables to prevent accidental disconnection. Lock

pins and safety cables are listed in Section 9.1.

WARNING

Hose disconnection while under pressure can

cause serious injury or death. Use safety lock

pins and safety cables on all blast hose and air

hose coupling connections to help prevent

hose couplings from accidental disconnection.

4.1.3

Close the air-supply valve, start the compressor

and bring it up to operating temperature and pressure.

4.1.4

Slowly open the compressor air valve to

pressurize the air-supply line. Listen for noise that

indicates any open lines or leaks.

4.1.5

Do not allow anyone around the blasting area

who is not appropriately fitted with approved personal

protective equipment, per Section 4.2.

Air Induction Valve

Tensioning Knob

Water Valve

Shown fully Closed.

Water Connection

(Garden hose swivel)

Water Hose

Air Induction Port

Shown open.