Page 4

823036EN

02/11/2014

Cleco

®

Product Information

Remove the hammer from the vise and slip the cam

shaft and related components from the rear of the cam.

Remove the shock absorber (slight press fit) from the

rear of the cam shaft. The will allow removal of the

insulator, butt plate, cam roller and cam roller shaft.

Slip the cam from the rear of the hammer using caution

not to lose the timing pin.

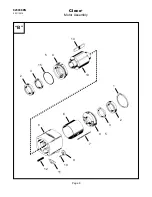

Motor Unit Disassembly:

Place the front of the motor housing on a cylinder (4-1/2”

I.D. x 5” long) and using a driver with a 2-1/8” O.D. drive

the rotor out of the rear bearing. This will allow removal

of the front bearing plate, rotor blades and rotor from the

housing.

Invert the housing on the fixture and use the rotor to

drive the rear bearing plate assembly from the housing.

The cylinder should not be removed from the housing

unless replacement is necessary. If cylinder replacement

is necessary, a 4-5/32” O.D. bushing driver (with a

suitable relief for the alignment key) should be used to

press the cylinder out of the housing.

Remove the rotor bearings from the bearing plates. It

is recommended that the rotor shaft seals be replaced

every time the tool is serviced.

Note: Unless the o-rings located on the O.D. of the

bearing plates are severely damaged, they should

not be removed. If o-ring replacement is required, the

new o-rings must be installed using a fast cure contact

adhesive such as Loctite 404.

For cleaning and inspection of the muffler plates, remove

the retainer screw.

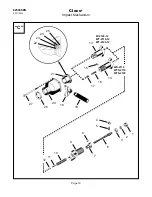

Handle Disassembly:

Disassembly of the inside trigger and outside trigger

models are the same procedure.

Removing the air inlet bushing will allow removal of

the o-ring, air inlet screen, throttle valve spring, throttle

valve, throttle valve seal and throttle valve pin.

Do not remove the throttle pin bushing unless

replacement is necessary. To remove the throttle pin

bushing, tap the I.D. of the bushing using a 1/4”-20

thread tap and then insert a 1/4”-20 bolt of adequate

length and clamp the bolt in a vise. Carefully drive the

handle away from the vise using a soft mallet.

If the trigger requires replacement, only the trigger pin

needs to be removed.

Maintenance - Reassembly:

Cleaning and Inspection:

Clean all parts in a solvent and inspect for excessive

wear or damage. If the rotor blades measure less than

7/16” wide on either end they must be replaced. Rotor

bearings should be replaced if they feel rough after

cleaning or show excessive looseness.

Handle Assembly:

When installing the trigger use a pin slightly smaller than

the hole in the handle to locate the trigger when driving

the trigger pin into the handle.

If the throttle valve bushing was removed, the replacement

bushing must be pressed in to a depth of 1-15/16” plus

or minus 1/64” from the bottom face of the handle.

Inspect the throttle valve seal for wear or damage. If

replacement is necessary, push the new seal (cupped

face first) onto the throttle valve from the tapered end.

Clean the threads on the air inlet bushing and replace the

o-ring if necessary. Apply Loctite® # 271 to the threads.

Install the throttle valve pin and throttle valve assembly

into the handle. Place the air inlet screen and throttle

valve spring into the air inlet bushing and assemble into

the handle. Tighten the air inlet bushing to a minimum of

80 ft. lbs. torque.

Motor Unit Assembly:

Install the muffler plates into the motor housing and

secure with the retaining screw.

During reassembly of the bearing plates, the rotor

shaft seals should be installed with their “lips” facing

out (visible after installation). When installing the rotor

bearings press on the bearing’s outer race. Lubricate

both the seals and rotor bearings with 30W oil before

assembly into the motor unit.

Inspect the o-ring on the front bearing plate and replace

if necessary.

Note: The bearing plates are identical.

However, this o-ring is only used on the front bearing

plate.

If the cylinder was removed, the new cylinder (with

alignment key in position) must be pressed in from the

rear of the motor housing to a depth of 5/8” from the rear

face of the motor housing.

Lubricate the o-rings on the O.D. of the rear bearing

plate and press this assembly into the motor housing.

During installation, make sure the o-rings line up with

the air ports in the motor housing.