Page 3

823036EN

02/11/2014

Cleco

®

Product Information

The original language of this manual is English.

Product Safety Information:

Intended Use:

This air assembly tool is intended for tightening of

threaded joints or running down fasteners. Use only for

their designated purpose. Do not use as a hammer, lever

or other improper usage that can cause tool damage

and operator injury.

For additional product safety information refer to Apex

Tool Group, LLC or Apex Tool Group GmbH & Co. OHG

document CE-2004, General Safety Impact Wrenches.

This air assembly tool must not be modified unless

approved in writing by Apex Tool Group, LLC or Apex

Tool Group GmbH & Co. OHG. All safety devices must

be properly installed and maintained in good working

order.

Air Line Lubrication:

Use Apex Tool Group, LLC or Apex Tool Group GmbH

& Co. OHG’s lightweight air tool oil 500021 (available

in quantities shown in the following chart) or an SAE-5

lightweight spindle oil.

Oil Reservoir (30W):

The oil reservoir marked “30W Oil” should not require

attention until the tool is disassembled for regular

inspection and maintenance. However, it is suggested

that the oil level be checked periodically. If oil is required,

approximately 1.25 fluid ounces of a good grade 30W oil

should be added to the reservoir.

Air Supply Line:

Service and Repair:

Tool service and repair should be performed by a

properly trained technician or an authorized Apex

Tool Group, LLC or Apex Tool Group GmbH & Co.

OHG Center. Refer to the last page of this manual for

locations.

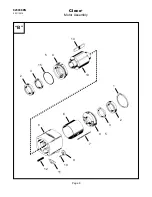

General Disassembly:

Always disconnect the air supply before performing any

maintenance on these tools.

Remove the four (4) hex nuts and washers from the

handle area. Remove the handle assembly, reversing

valve, handle gasket and the motor clamp seal from the

motor housing.

Drive the four housing bolts out the front of the motor

assembly. The anvil housing assembly can now be

removed allowing the impacting mechanism to slip out

the front of the motor assembly. It may be necessary to

rotate the anvil housing to clear the anvil and hammer

lugs.

Anvil Housing Disassembly:

It is recommended that the anvil housing seal (867993)

be replaced every time the tool is serviced. The seal can

be pried out using a screwdriver.

The anvil housing seal must be removed if the anvil

housing bushing requires replacement. The anvil

housing bushing can be pressed out the rear of the anvil

housing using a 2-3/16” diameter bushing driver.

Impact Mechanism Disassembly:

Clamp the hammer, horizontally, in a soft jawed vise

and drive the anvil away from the hammer using a soft

mallet. This will permit the anvil pin, spring clip and

hammer spring to be removed from the front of the cam

shaft.

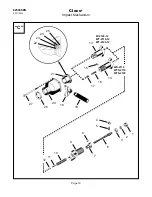

Note: Spline drive models, if any of the socket retainer

parts require replacement, a 5/32” hole should be drilled

in the socket retainer plunger. Refer to the following

illustration. Insert a pin punch into the drilled hole and

lightly tap the punch under the socket retainer pin. Pry

on the punch to pop the pin out of the pocket in the

plunger.

WARNING

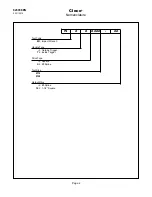

Part No.

Packaged

Designation

540397

1 Quart (0.94 liter)

Airlube 10W/NR-420LB DR

533485 1 US Gallon (3.78 liter) Airlube 10W/NR-420LB DR

Parameter

Description

Air Hose

Hose diameter: 1/2" (12,7 mm)

Maximum length: 16.4' (5 m)

Working pressure

range

58 to 101.5 psi (400 to 700 kPa)

Recommended: 90 psi (620 kPa)

Compressed air

Air quality according to ISO 8573-1,

quality class 2.4.3

The compressed air must be clean and dry.

5/32” Drilled Hole